Radian Oil and Gas ... improving its processes to exceed customer expectations

Radian Oil and Gas ... improving its processes to exceed customer expectations

RADIAN Oil and Gas (Radian O&G) services started operations in 2010, led by a strong team with years of experience in the Middle East market in sales of top level engineering products and consulting.

The company is committed to helping customers conserve energy and operate more efficiently through a broad range of product / service solutions which reduce carbon dioxide (CO2) emissions while saving fuel, water and electricity.

“As a company we are passionate about sustaining the energy needs of future generations coupled with the responsibility to protect and preserve the environment. That has been at the cornerstone of our business strategy,” says Radian Oil & Gas general manager Mansoor Khan.

He says Radian had achieved considerable success in a short span of two years with its proactive approach, close relationship with its customers and mutually beneficial partnerships with its principals.

Radian is characterised by an in-depth technical knowledge of the client’s requirements with the motivation to be a market leader and represents some of the world’s renowned companies having unique products in the areas of its operation.

|

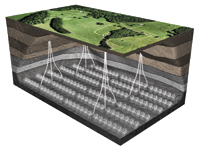

The company is an engineering solutions and specialty products provider for a wide spectrum of industries in areas such as heat transfer, combustion optimisation, energy conservation, solar power and solar water-heating systems.

The feedwater dearators that it supplies are of a patented single-shell design that can give 7 ppb (parts per billion) or less oxygen without the use of chemical scavengers and a steam loss of eight times less in comparison to the two-tank design.

It has more than 2,000 references worldwide.

Existing dearators can be retrofitted with minimum investment and short shutdown to give increased capacity, large turndown and greatly reduced operating costs.

To optimise combustion operations, Radian provides burners with lowest NOx (oxides of nitrogen) and best performance together with flame monitoring systems, combustion control (BMS – burner management systems) and fuel/air ratio control, igniters, fuel handling systems, and water level measurement (boilers). “All these work towards improved operations, reduced fuel consumption and emissions,” Khan says.

Many of Radian’s customers are aware that an imbalance in combustion contributes significantly to the high cost of ownership through poor process efficiency, poor process control, increased maintenance costs, unplanned shutdowns, high fuel costs and difficulty in meeting stringent pollution regulations.

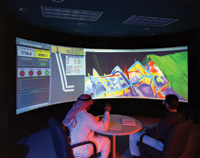

“To this end, our patented acoustic pyrometer is an advanced industrial non-intrusive high-end monitoring system that can help in balancing combustion,” says Khan.

He continues: “It’s a temperature mapping system that gives average gas temperatures along multiple acoustic paths (24 individual paths) within a process and provides real-time planar spatial temperature distribution profiles. These temperature maps which no other technology can provide give operators real-time pictures of the fundamental thermal characteristics of the process.

“This information is critical to optimisation of efficiency, reduction of emissions, and service life extension of plant and process equipment (detection of hot spots) and has successfully been used in boilers, process heaters in refinery and petrochemical plants.”

Most operating plants suffer from frequent failure of steam traps (failed open/closed) which result in large steam loss, erosion, corrosion ad water hammer in the condensate/ steam line, and poor heat transfer.

To address this persistent problem, Radian has introduced a patented dual strainer venturi orifice steam trap that comes with a 10 year warranty (expected life of 20 to 30 years) with improved efficiency and reduced maintenance costs thereby providing reduced boiler fuel costs, improved heat transfer in process equipment, reduced CO2 emissions and at the same time eliminating need for replacing failed steam traps.

In a recent survey of a petrochemical plant, Radian found more than 60 per cent of the traps had failed, replacing all the failed traps with the new technology has a pay back of less than a year in terms of steam costs alone with many additional benefits including no new replacement steam traps required for at least 10 years.

Radian is also marketing dual-purpose patented gas turbine (GT) upgrading technology which provides power augmentation (10 to 15 per cent) and NOx reduction (up to 45 per cent) and can be used both in high temperature and high humidity.

It’s applicable on any gas turbine and has a small footprint; and the company can supply turnkey delivery with full warranty resulting in a fast return on investment (ROI) for customers.

Another area of Radian’s focus is water reuse, wastewater treatment up to zero liquid discharge. “Working together with a world leader in the field, we are supporting our clients with cutting-edge, sustainable water purification systems and technologies to address the region’s water scarcity challenges while minimising life cycle costs and environmental footprint,” says Khan.

Waste energy in any industry is a concern, but waste energy in the form of steam, exhaust gases can be utilised to produce chilled water by using a vapour absorption machine (VAM), says Radian adding that it has got expertise in providing complete turnkey solution with a fast payback on investment.

In the same activity, Radian is working on renewable energy by providing complete solutions for solar power and solar water heating systems.

Radian is also promoting fuel cell technology with an electrochemical device that combines hydrogen fuel (from natural gas) and oxygen from the air to produce electricity, heat and water with a much higher efficiency than an internal combustion engine. “Fuel cells are among the cleanest energy-generation sources in the world and meet the strictest emission standards,” Khan adds.

“Radian will continue to strive to be the best in its areas of focus while keeping our customers in mind with every decision we make and every project we complete. We will continuously improve our processes to meet and exceed expectations and continue to create an environment throughout the company which causes this philosophy to become a way of life,” he concludes.

.jpg)