Shepherd ... focusing on an integrated systems model

Shepherd ... focusing on an integrated systems model

When viewed as a vehicle for process transformation, metering opens the possibility to produce energy safely with zero carbon intensity and the least possible environmental impact, Mike Shepherd tells OGN

The idea of the energy trilemma has been around for nearly a generation and remains largely unsolved to date.

The central question remains: How can affordable, reliable energy with lower carbon dioxide emissions be ensure?

Mike Shepherd, Group Business Development Director, Alderley says: "One of the most overlooked areas in our energy systems that can make the biggest impact in addressing the challenge of the energy trilemma is understanding the value of energy, and this is done by metering."

He says by accurately measuring the flow of energy in either liquid or gaseous form, that is, ‘flow measurement’, the quantity, quality, and impact of the energy or gaseous emissions, such as CO2, in a particular system can be determined.

"But if we think of metering as a tailored solution and consider the value of the data in a measurement system rather than just as a piece of ‘kit’, we will be able to make serious inroads in ensuring that the energy produced in a particular system is processed, distributed, and consumed at the optimum value and efficiency."

This entails viewing metering and measurement as a vehicle for organisational and process transformation rather than simply a commodity for compliance.

It opens the possibility to produce energy safely and efficiently with diminishing or zero carbon intensity and the least possible environmental impact.

It means that the energy is the optimum quality for its purpose and is without contamination, and that the energy is transferred and distributed effectively without loss.

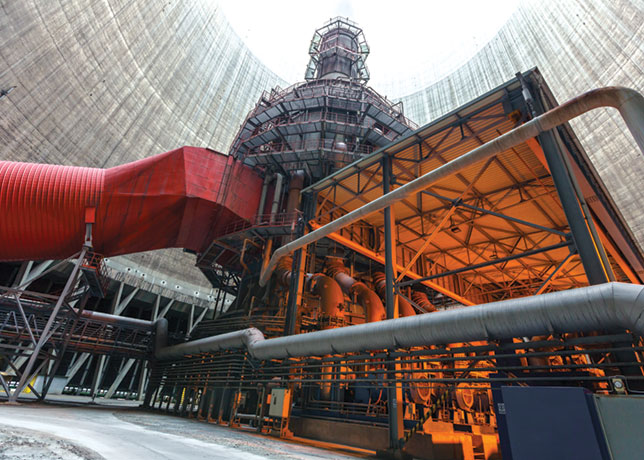

INTEGRATED SYSTEMS MODEL

Shepherd says the point around an integrated systems model is important because "we are talking about energy produced on a global scale".

|

A holistic approach to metering can help organisations obtain huge operational efficiencies |

Therefore, if energy production can be improved through efficiency measures that deliver an improvement of a few percentage points the results could be significant.

He adds: "If we get this right, we can revolutionise the performance of an organisation’s energy assets."

Measuring the production outputs using accurate metering systems will provide the tool to improve efficiency in terms of costs and emissions.

It is not without good reason that the Fatih Birol, Executive Director of the International Energy Agency (IEA), has consistently called for energy efficiency to be elevated as part of the energy transition.

Birol has said previously: "At IEA, we call energy efficiency ‘the first fuel’ – which shows the significance of energy efficiency."

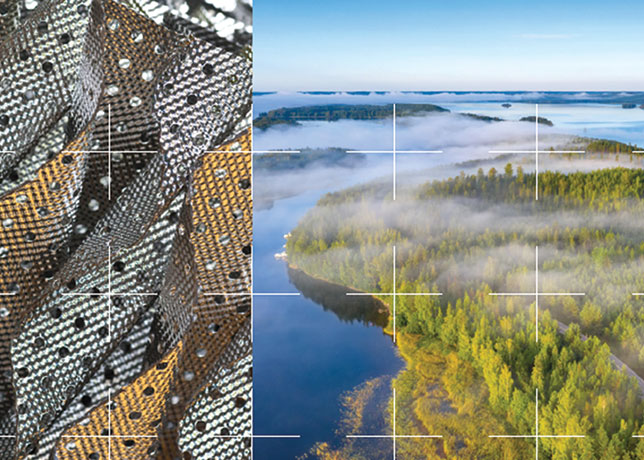

Furthermore, the principle of energy efficiency covers all energy sources as global systems cannot rely on one source alone.

Renewables, hydrogen, nuclear and hydrocarbons all have a role to play in powering our modern highly industrialised economies.

When one factors in the impact of new digital technologies that can improve the measurement capability of specific instruments, it is easy to see how maximising the performance and efficiency of energy assets represent such a huge opportunity to contribute to a global energy system in transition.

Alderley’s role within this is instructive; the company acts as an interface operating between end-user operators and original equipment manufacturers (OEM).

"We help our clients understand the importance of accurate metering and the associated uncertainty of measurement to provide data to improve efficiencies. This is an important contractual component of many agreements, specifications, and international regulations," says Shepherd.

What brings home metering’s significance is its potential financial impact.

FINANCIAL RAMIFICATIONS OFTEN OVERLOOKED

In financial terms, the expression of uncertainty allows us to estimate the degree of exposure caused by a measurement.

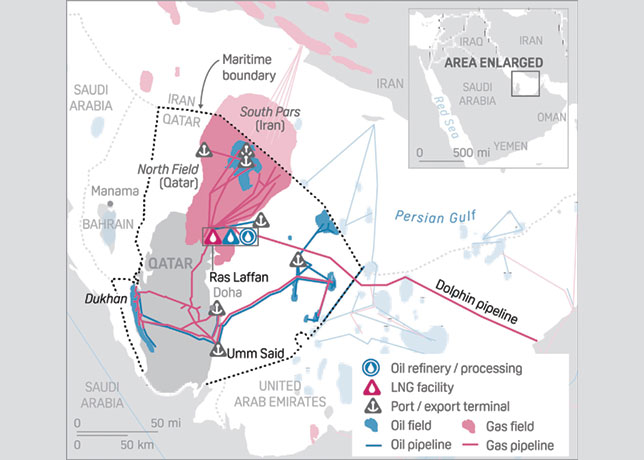

For example, if a platform produces 50,000 barrels per day (bpd) measured at an uncertainty of 5 per cent, the true value of the production could be between 47,500 and 52,500 bpd.

At a price of $100 per barrel, this is a potential exposure of +/- $250,000 per day or in financial terms nearly $100 million per year.

If selling hydrocarbons, for example, you could be handing over $100 million more than you get paid for; or if buying, you could get $100 million less than you paid for. The figures speak for themselves.

The role of a measurement engineer is crucial in today’s changing energy system as they will ensure that the uncertainty of a given system is aligned to the agreed uncertainty in any given sales contract, production agreement or international regulations.

Understanding and controlling uncertainty is more than just compliance.

Better control of uncertainty provides a better assessment of the organisation’s energy operations in terms of efficiency, performance and future improvement.

THE LOWER THE UNCERTAINTY, THE BETTER

The lower the uncertainty, the better the performance and reduced risk. This in turns equates to improved value and efficiency.

Measurement can detect deviations in performance between stations but only when the uncertainty is managed.

In the previous example, an organisation might lose nearly $100 million per year and be completely unaware of the loss.

This is even without considering the environmental impact of the unaccounted-for energy or the consequences of a similar deviation between reported and actual CO2 emissions.

So, when the performance is managed, the value of energy assets is maximised and loss minimised. Other benefits include:

• Proving compliance with regulations and agreements.

• Supporting optimal operation of products.

• Helping the detection, prevention and elimination of faults.

• Reducing opex and unnecessary intervention.

• Health, safety and environmental improvements.

What is more, for emerging technologies like hydrogen or CCUS, the potential for uncertainty is high given the relative immaturity and lack of guidelines and standards in the respective sectors.

When trust is low and technology immaturity high, industry needs partners with whom to work with to provide the best available insight and maximise value and efficiency.

That’s where Alderley comes in as it offers end-to-end cost-competitive metering solutions that are designed with digital capability and performance management at its core.

It is supported in this endeavour by its fellow group company Kelton.

By focusing on a holistic approach to metering, organisations in the global energy sector will be able to focus on making huge efficiencies to their operations.

By instituting change at a systemic level, flow measurement can embed itself as a driver of change across an energy sector in transition.