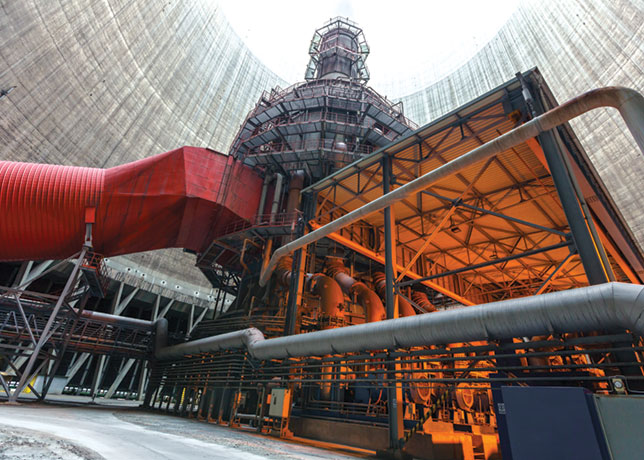

CB&I's design of a LH2 containment system for carriers. Image: CB&I/Alesandro14 – Shutterstock

CB&I's design of a LH2 containment system for carriers. Image: CB&I/Alesandro14 – Shutterstock

CB&I, Shell's and DNV have each leveraged their expertise to yield a design that has the potential to unlock expansive opportunities for the transportation of hydrogen on a massive scale

In a significant move towards revolutionising global hydrogen supply chains, CB&I, in partnership with Shell and with support from DNV, has achieved Approval in Principle (AiP) for a large-scale, liquid hydrogen (LH2) cargo containment system.

This breakthrough has the potential to unlock expansive opportunities for the transportation of hydrogen on a massive scale.

The AiP marks a pivotal moment in the journey towards establishing a robust infrastructure for hydrogen transportation.

Leveraging CB&I's expertise in onshore LH2 storage, Shell's experience in hydrogen carriers, and DNV's regulatory proficiency, the collaborative effort has yielded a design poised for further development.

Notably, this innovation promises to facilitate the transport of significantly larger quantities of hydrogen, thereby driving down the cost per unit of energy.

Hydrogen, heralded for its carbon-free properties, stands as a linchpin in global efforts to combat emissions, particularly when produced through electrolysis.

However, the logistical challenges inherent in its transportation necessitate innovative solutions.

While pipeline networks can suffice for certain regions, long-distance transportation—such as from Asia to Europe—demands alternative methods, making shipping indispensable.

The transportation of hydrogen in liquid form offers practical advantages over gaseous counterparts, primarily due to its higher energy density.

Yet, the intricacies of LH2 shipping pose unique challenges, particularly concerning safe storage.

Tom Klungseth Ostvold, Principal Engineer at DNV Maritime Advisory, underscores the complexities: 'To liquefy hydrogen, it must be cooled to minus-253 deg C. Once this is done, the liquefied hydrogen needs to be stored in tanks with the highest standards in vacuum insulation.'

Drawing from CB&I's extensive experience in land-based liquid hydrogen storage, the adaptation of established technology holds promise for elevating safety standards in LH2 transportation.

David Creech, Director of R&D at CB&I, explains: 'CB&I’s LH2 cargo containment system for LH2 carriers is based on our technology for large-scale onshore LH2 storage.'

The integration of proven designs, backed by over 60 years of operational history, instills confidence in the feasibility of LH2 transportation.

However, the transition from onshore to maritime applications necessitated nuanced adjustments to accommodate the rigors of shipping environments.

Notably, the presence of cyclic loads from ship motions posed a significant challenge.

Nevertheless, collaborative efforts between CB&I and Shell, supplemented by the expertise of DNV, facilitated the seamless adaptation of LH2 tank designs to meet maritime standards.

James Cocks, IRD Project Manager at Shell International Trading and Shipping Company, highlights the symbiotic nature of the collaboration. He says: 'CB&I would leverage their extensive experience in LH2 storage to develop the containment system, and Shell would provide much of the maritime expertise.'

This partnership culminated in the development of a concept design for a 20,000 cu m LH2 carrier, laying the groundwork for subsequent initiatives aimed at refining the design for maritime applications.

Navigating maritime regulations and safety codes proved to be a formidable task, particularly given the nascent nature of LH2 transportation technologies.

Despite the absence of specific guidelines for LH2 cargo containment systems, DNV's regulatory acumen played a pivotal role in bridging regulatory gaps and ensuring compliance with industry standards.

The achievement of AiP signifies a significant milestone in the evolution of LH2 transportation, setting the stage for further advancements in hydrogen supply chains.

Cocks emphasises the importance of expeditious progress, stating: 'To support the role of liquid hydrogen in the energy transition, it’s critical that its potential as a viable energy carrier is demonstrated with urgency.'

Looking ahead, the success of the collaboration has spurred discussions on scalability, with CB&I's technology poised to accommodate larger tank sizes capable of supporting carriers up to 200,000 cu m.

Furthermore, with hydrogen poised to play a pivotal role in the future energy mix, ongoing research and development efforts are imperative to drive technological innovations.

As the project exemplifies, collaboration with maritime experts will be indispensable in navigating regulatory landscapes and ensuring the safety and viability of LH2 transportation.

Ostvold affirms DNV's commitment to supporting technological advancements in hydrogen infrastructure, underscoring the paramount importance of safety in driving innovation forward.

In conclusion, the Approval in Principle for a large-scale LH2 cargo containment system represents a significant leap forward in the quest for sustainable energy solutions.

With collaborative efforts driving innovation, the stage is set for a transformative shift towards leveraging hydrogen as a cornerstone of the future energy paradigm.