Perez ... transparency focus

Perez ... transparency focus

Finboot’s MARCO Track & Trace can mitigate risks and provide a competitive advantage for fuel producers to strengthen their market position and reputation, Juan Miguel Perez tells OGN

In today's industrial landscape, transparency in the supply chain is paramount, particularly within the realm of sustainable fuels.

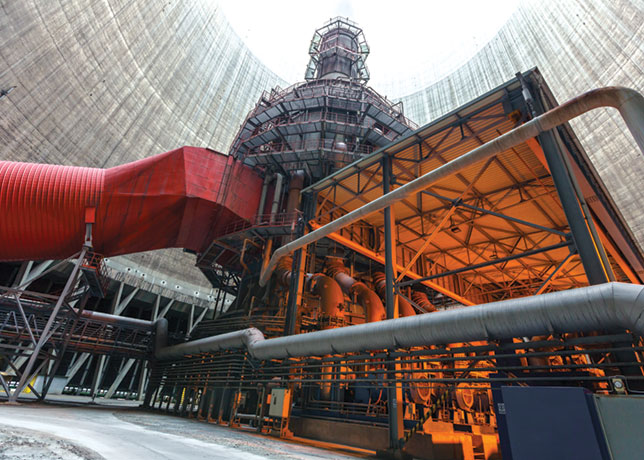

Finboot's MARCO Track & Trace solution is a cutting-edge digital traceability ecosystem designed to empower large industrial companies.

The technology enhances supply chain transparency by enabling the configuration of intricate industrial workflows for seamless supply chain mapping.

In an exclusive interview, Juan Miguel Perez, CEO and Co-Founder, Finboot, tells Abdulaziz Khattak of OGN energy magazine that at the core of the solution lies the simplification of data gathering throughout each stage of the sourcing, production, and distribution process.

By creating a digital representation of industrial processes, efficient data exchange is facilitated, ensuring comprehensive visibility and accountability.

The following are excerpts from the interview:

Can you provide an overview of the demonstrator project on sustainable fuels that Finboot is working on in collaboration with Repsol? What are the key goals and milestones of this project?

Global energy company, Repsol takes a technology-neutral/multi- multi-threaded approach to decarbonisation and the race to net-zero.

Its stance is that no single technology or solution alone can get solve the climate challenges we face.

|

There are concerns in Europe about imported virgin cooking oil being sold as used |

That is why as part of the company’s net-zero strategy efforts are being placed on electric mobility, hydrogen and transition fuels.

Transition fuels are temporary, or ‘stepping stone’, solutions to accelerate the transition to a low and net-zero carbon economy.

These include the likes of hydrotreated vegetable oil (HVO), sustainable aviation fuels (SAFs) and other plant or waste-based fuels.

The fact these fuels are made from plants and waste, is what makes their lifecycle emissions lower or even net-zero in comparison to fossil fuels.

But it means Repsol needs to monitor and trace the production process, the provenance of raw materials, and the end-to-end chain of custody is critical to ensure a transparent, and reliable decarbonisation.

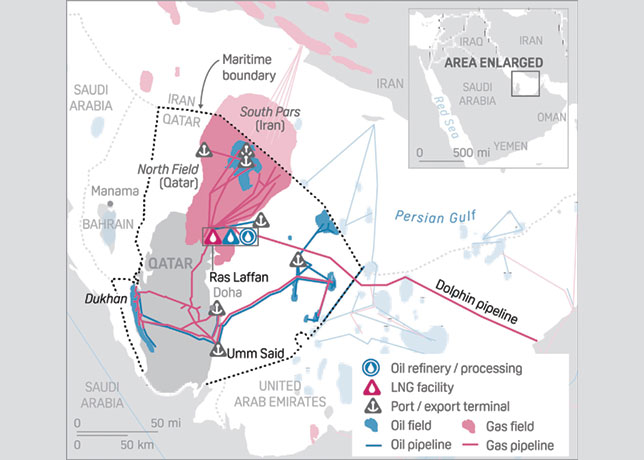

In 2023, Repsol launched an initial pilot for traceability of HVO.

Repsol expanded its use of Finboot’s traceability solution MARCO Track & Trace to cover the sourcing, distribution and consumption of HVO by one of their clients.

With MARCO, Repsol was able to gather an evidence trail throughout the supply chain, which included declarations of sustainability and certifications, such as International Sustainability and Carbon Certification (ISCC).

It also kept a real time watch on the chain of custody and monitored inflow and outflow of all storage facilities.

Lastly, taking advantage of its connected service station and connected vehicles; Repsol was able to monitor consumption of HVO, create a fully auditable link from the raw material (vegetable oil) to the exact vehicle that consumed the low carbon fuel.

The same technology can be extended to SAF for air travel and to similar technologies that are being developed for maritime shipping.

How does Finboot's expertise in digital traceability ecosystems contribute to the development and implementation of sustainable fuels in the energy sector, particularly in collaboration with Repsol?

In layman’s terms, Finboot’s expertise helps keep energy companies’ honest when it comes to their environmental, social and governance (ESG) and sustainability claims.

As the production volumes of low carbon products quickly accelerates to meet market demands, so do the supply chain risks and the need for more robust visibility and data sharing solutions that will mitigate any wrongdoing throughout the value chain.

What typically was being managed by manual oversight and recordkeeping, now needs to evolve to a more scalable digital traceability ecosystem.

This is exactly where Finboot’s technology plays a key role.

Finboot’s expertise on traceability also helps companies guarantee there is no misplacement of emissions.

Another huge challenge of the energy transition is where alternatives such as electrification can be counterproductive if we don’t trace the source of the electricity and the provenance of battery raw materials.

Finboot’s has been working with Repsol for over six years now, and we have been collaborating with multiple business units and with solutions that have been scaled and are used by hundreds of users across Repsol’s industrial sites in Spain and Portugal.

In what ways does Finboot's digital traceability ecosystem enhance supply chain transparency for large industrial companies, especially in the context of sustainable fuels?

Our technology enables the configuration of complex industrial workflows for supply chain mapping.

Basically, we help our clients by creating a digital representation of their industrial process, and by simplifying the way data is gathered through each sourcing, production and distribution stage.

Our solution includes web applications, which clients can use to provide supplier and customer portals to gather and share data.

We also include integration capabilities and are fully interoperable with legacy systems, such as ERPs (Enterprise Resource Planning) or SCMs (Supply Chain Management) tools.

When it comes to sustainable fuels, this is critical, especially with the provenance of raw materials being of special importance to guarantee the sustainability of the fuel.

As an example, according to Transport & Environment, Europe’s leading clean transport campaign group, 80 per cent of Europe’s used cooking oil (one of the raw materials used to produce HVO and SAF) is imported; raising concerns over fraud where virgin oils can be sold as "used".

Adopting Finboot’s MARCO Track & Trace mitigates these risks and provides a competitive advantage for fuel producers to strengthen their market position and reputation.

Given the pressure on the transport sector to decarbonise, how does Finboot envision its collaborative efforts with Repsol impacting the journey to net-zero emissions, specifically in air, land and maritime transport?

We at Finboot are very aligned with Repsol in that multi-threaded/technology-neutral approach.

We believe transition fuels will play a crucial role over the next few years, as greener technologies improve their maturity and scalability capabilities.

Moreover, our view is regardless of the technology used for decarbonisation, digital traceability will be a must-have.

All net-zero, ESG, and sustainability claims must be backed by substantial and reliable data. Finboot’s technology can help provide that digital ecosystem.

Could you elaborate on the technological solutions or innovations that Finboot is bringing to the table in the development of sustainable fuels, and how these solutions differentiate themselves in the market?

Finboot’s solutions are focused on three major unique selling points:

• We optimise supply chain efficiency by improving visibility, managing documentation and data accuracy, and engaging with suppliers and customers.

• We facilitate compliance to both regulatory requirements like RED II and voluntary frameworks like ISCC.

• We enable Digital Product Passports to provide customer and consumer facing data to ultimately enhance brand value.

What do you foresee as the potential impact of the sustainable fuels demonstrator project on the market in the short- to medium-term, and how might it influence broader trends in the energy and transport sectors?

The short-term goal is to align all stakeholders on the importance of transition fuels and position them as a reliable alternative for rapid decarbonisation, for which traceability is key.

The medium-term the goal is to scale this initial demonstrator as, in parallel, energy players scale production of these fuels.

As we continue to succeed in these initiatives, we envision digital traceability becoming standard practice to substantiate sustainability credentials in this and any other low-carbon solutions.

From a global perspective, how do you see the role of sustainable fuels in mitigating climate change, and what opportunities do you believe exist for Finboot to contribute to a more sustainable future?

Finboot has shown that it has the technology and the industry know-how to lead the way in the deployment and adoption of digital traceability solutions for sustainable supply chains.

We have strong customer relationships in our three core segments of energy, chemicals and steel with several global players like Repsol, SABIC and Cepsa.

Our technology has been proven to solve real pain points for these industrial clients, and to scale to meet the strict requirements of enterprise policies on data and cybersecurity.

We now move to accelerate the commercial adoption of our technology which will help consolidate Finboot’s leading role as we transition to a more sustainable future.

By Abdulaziz Khattak