Pemex facility ... upgrades changing the face of Mexican petroleum industry

Pemex facility ... upgrades changing the face of Mexican petroleum industry

Pemex’s (Petroblas Mexicanos’) oil refinery expansion in Cadereyta, Mexico, is continuing apace ready for an upturn in diesel and gasoline sales.

For a year previously to its implementation the plant had been undergoing tests to guarantee safety and efficiency.

The Cadereyta Refinery Reconfiguration Project (CRRP) is improving the structure of the Mexican petroleum industry, which is set for an upturn in sales of gasoline and diesel in northern Mexico. It was an unprecedented huge-scale construction, building ten new plants, expanding four plants and constructing a crude oil pipeline covering 1,317km. Fourteen other plants, including a refinery plant producing 155,000 barrels per day of fuel and a 65,000 barrels per day fluidised catalytic cracking plant, have been revamped, modernised and expanded.

The project was delayed twice. The first time was for a year in 1997, when Pemex extended the bid submission date up to October 1997, even though the tender documents were issued in the middle of 1996. The second time was for a year in 2000 because of Force Maejure, Pemex Acts and Omission and additional works requested by Pemex.

Pemex granted an extension to the completion date from 2nd July 2000 to April 21st, 2001. The work was carried out under a public works financing project that had not been used before in Mexico. As soon as the plant was completed, the consortium CONPROCA handed the refinery back over to Pemex.

The general objective of Mexican government’s five-year development plan is to strengthen the energy sector to promote economic and social growth. The policy has three main objectives: to achieve a rapid and efficient expansion of the energy sector, eliminating present lags; to promote key investment for long-term growth with strong private participation; and to strengthen and improve the efficiency of public-sector enterprises.

The upgraded and expanded Cadereyta refinery is now able to increase gasoline production and cut down on the 100 thousand barrels per day of high-grade gasoline it previously imported. The project has boosted the northern refinery’s output of unleaded and cleaner diesel, reduced sulphur emissions, and can better process heavy crudes.

The winning consortium, CONPROCA, led by SK Engineering and Construction was awarded the contract in November 1997. SKEC was in charge of financing, engineering, procurement, construction and commissioning for the whole project as a Consortium leader.

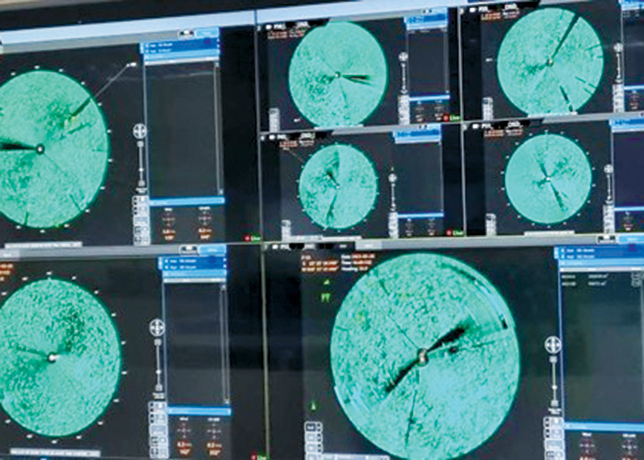

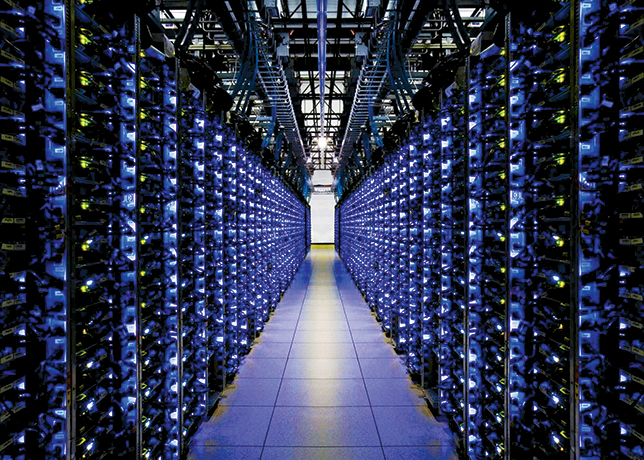

Other leading members were Siemens, who covered the engineering and construction of all electrical instrumentation. Siemens’ role in this project was to modernise and install the control systems for the refinery, enabling the plant to double production of gasoline, diesel, and kerosene. It implemented the automation systems for point-of-sale terminals and the Scada system for pump station monitoring and remote control. It also divided the Cadereyta crude oil pipeline into various sections.

Siemens have awarded a contract to ILF Consulting Engineers for a 1,200km 24in crude oil pipeline. The company has provided extensive consultation in process hydraulics, operation commissioning and line-fill of the pipeline system. They have also provided a definition of the automation concept, issue of detailed logistics, contract management for application-specific software and consulting regarding contractual matters. The pipeline will transport oil to the refinery from the oil production areas in south eastern Mexico, and also improves the capacity of other pipelines in the area.

Rotork Houston successfully bidded to supply 800 IQ actuators and Pakscan systems for the refinery. It won the contract despite fierce competition from Europe and the USA, all of which were bidding aggressively. Tribasa began to construct the long distance crude line, but went bankrupt in October 1998. Since then,SKEC has taken over all responsibilities of Tribasa for the Cadereyta Project and carried out all construction works for the long distance pipeline.