Jan Strohmeier

Jan Strohmeier

Jan Strohmeier, Digitalisation Manager, Endress+Hauser, explores how Ethernet-APL connectivity is established, how critical data and insights are leveraged, and the prerequisites for adopting this cutting-edge technology in the process landscape

The introduction of Ethernet-APL marks a significant breakthrough in field device connectivity, enabling high-speed, multi-master communication that unlocks new possibilities for industrial automation.

This next-generation technology transforms the way field instruments connect and communicate, bridging the final stretch in digitalisation and empowering plants with faster, more reliable access to data, a spokesman for Endress+Hauser tells OGN energy magazine.

|

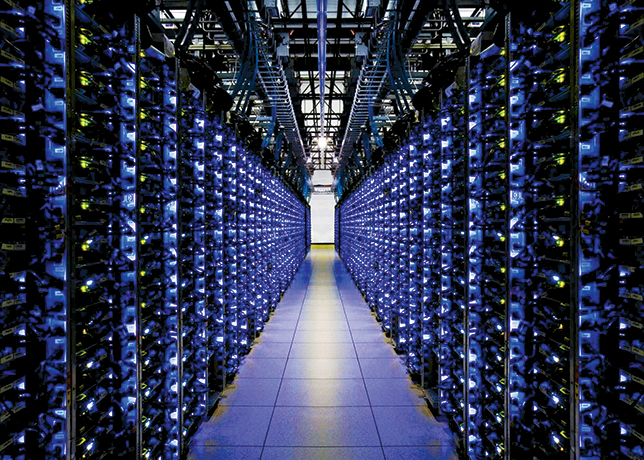

Unmanned planned operation is made easy through Ethernet-APL |

ETHERNET-APL AND PROFINET: SHAPING THE FUTURE OF INDUSTRIAL NETWORKS

Ethernet-APL (Advanced Physical Layer) enables long-distance, high-speed digital communication in the most demanding field environments.

Combined with PROFINET, one of the most robust and widely adopted industrial Ethernet protocols, it allows scalable, deterministic communication from the field to the control level.

The physical connection is a single twisted pair cable, which provides power and communication at the same time. The connection with communication over the same cable is best known to the industry as 4-20 mA Hart.

Enhancements on the communication speed, which is now 10Mbit/s, and Ethernet bases is opening the multi-master and multi-protocols over the same connection.

The Ethernet-APL connection is also certified to go into EX areas to have one connection type for any application and need.

This allows the communication on ProfiNet between the controller and the device to exchange measuring data and at the same time the connection to the build in web server in the device for any configuration and troubleshooting without the need of any service tool. Integration into an AMS system is now much as more data can be faster and easier exchanged.

|

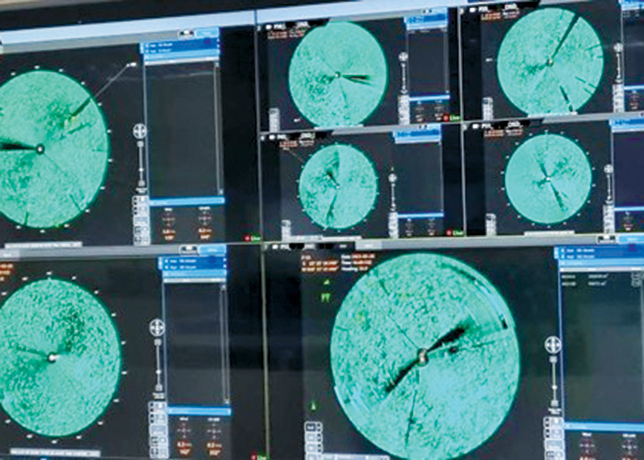

With Ethernet-APL it is possible to realise different topologies |

With the easy access to configuration and trouble shooting from anywhere in the network, the unmanned planned operation is now within reach.

ENABLING SEAMLESS CONNECTIVITY & BRIDGING THE OT & IT WORLD

Endress+Hauser’s FieldEdge SGC500 is a smart connectivity gateway engineered to enhance remote monitoring and industrial asset management.

Designed to connect seamlessly to field devices via PROFINET, the SGC500 acts as a bridge between operational technology (OT) and information technology (IT), enabling real-time data acquisition and transmission to the Netilion IIoT ecosystem.

Through this integration, users can monitor process variables, receive instant device diagnostics, and gain a holistic view of plant performance - all from a centralised cloud platform.

The SGC500 supports a wide variety of Ethernet-APL-enabled field instruments such as:

• Flowmeters.

• Pressure and temperature transmitters.

• Liquid and gas analysers.

• Level sensors.

The FieldEdge SGC500, fully compatible with both technologies, empowers plants to break data silos and unlock the true potential of digitalisation.

NETILION ECOSYSTEM & FIELDEDGE: UNLOCKING SMART INSIGHTS

|

The FieldEdge SGC500 enhances remote monitoring and industrial asset management |

More than just a gateway, the FieldEdge SGC500 is a key enabler in the Netilion ecosystem – Endress+Hauser’s suite of cloud-based industrial services.

With secure remote access, users can tap into tools like:

• Netilion Health, for real-time diagnostic alerts and recommendations.

• Netilion Analytics, for lifecycle and installed base optimisation.

• Netilion Library, a storage place for configuration, calibration and verification reports.

• Netilion Value, to track process values and monitor trends.

This level of visibility empowers predictive maintenance, reduces unplanned downtime, and ensures regulatory compliance with automatically generated verification reports and audit trails.

KEY USE CASES & BENEFITS

• Enhanced asset management: Get a clear view of all connected devices, their health status, and operating conditions.

• Secure remote access: Enable remote support, parameterisation, and diagnostics from anywhere.

• Lower operational costs: Minimise site visits with automated calibration reminders and condition-based maintenance.

• Sustainability: Reduced manual interventions and energy-efficient operations contribute to greener plant performance.

The FieldEdge SGC500, with its advanced PROFINET and Ethernet-APL capabilities, is a game-changer in the transition toward digital, data-driven industrial operations.

By integrating seamlessly with Endress+Hauser’s Netilion IIoT services, it delivers powerful insights that not only optimise plant performance but also support long-term strategic goals like sustainability, compliance, and cost-efficiency. As industries continue their digital transformation journey, solutions like the FieldEdge SGC500 will play a critical role in building smarter, safer, and more connected operations.