PetroHab’s HWSE System

PetroHab’s HWSE System

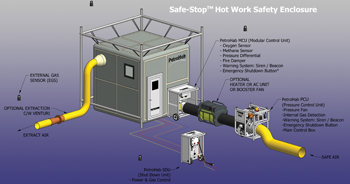

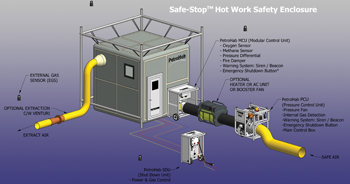

PetroHab, the world’s premier provider of Hot Work Safety Enclosures (HWSE), otherwise known as habitats, announced that its Safe-Stop and Safe-Work HWSE Systems have achieved ATEX & IECEx 3rd party certification.

The standard to which PetroHab’s HWSE Systems are approved is IEC 60079-13, the international standard governing the use of pressurised rooms in explosive areas.

Whenever hot work is conducted near potential flammables, such as in ATEX Zone 1 rated hazardous areas on oil rigs and at refineries, PetroHab’s HWSE System provides unrivalled safety. By continuously monitoring the pressure inside the HWSE, the fully automated Safe-Stop Modular Shut Down System (MSDS) enhances safety by only allowing hot work to be conducted inside the HWSE when there is a positive pressure environment.

This serves to prevent unwanted flammable gases from entering the enclosure, which allows hot work to be safely undertaken in the PetroHab HWSE, without the need to shut down the facility where the hot work is to take place.

Hermann Twickler of PetroHab in the UK, said: "Electrical Equipment operated in an explosive atmosphere is regulated by the International Electrotechnical Commission (IEC), and the international standard for Pressurised Rooms is IEC 60079–13. Only Pressurised Rooms that are 3rd party accredited to this standard can be operated within Zone 1 areas safely.

Twickler continued: "PetroHab’s Safe-Stop & Safe-Work HWSE Systems are the only 3rd party ATEX and IECEx certified HWSE Systems with automatic control systems and fit-for-purpose heat resistant panels in the world. Our HWSE Systems are compact & lightweight, and their innovation and certification surpass all other outdated systems on the market."

Samer Al-Azem of PetroHab in USA, said: "PetroHab has always had the best Hot Work Safety Enclosures (otherwise known as habitats) on the market. Our patented Quadra-Lock panel attachment system is unparalleled, allowing virtually limitless modularity and configurability, which practically renders obsolete the failure prone zippered "A" and "B" type panels currently used throughout the HWSE industry. Manufactured from a premium ANSI/FM4950 certified, US-made silicone-coated fiberglass cloth, our panels can withstand continuous temperatures of up to 1,000°F (540°C).

Al-Azem continued: "Moreover, our panels are stitched with virtually fireproof Kevlar thread to ensure their strength and high temperature resistance. These features make our HWSE the industry standard for safety."