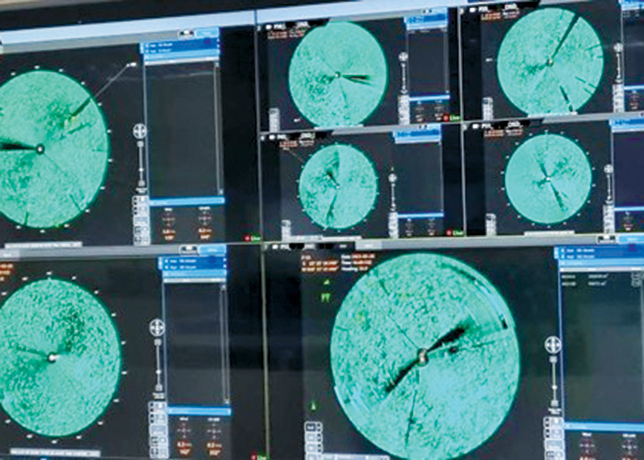

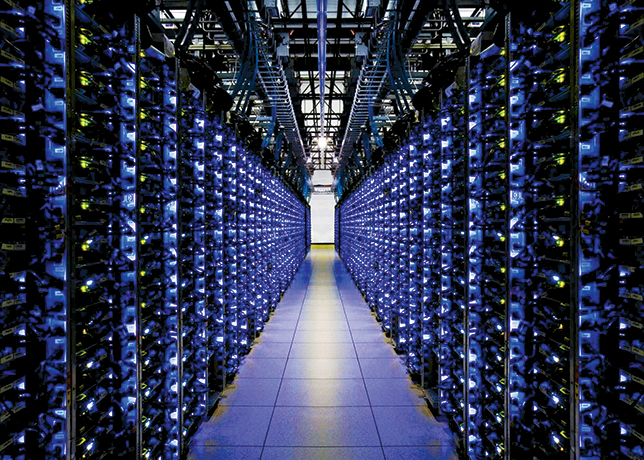

ENTIS offers remote monitoring capabilities

ENTIS offers remote monitoring capabilities

The ENTIS inventory system uses the latest tank management and custody transfer technologies to reduce inventory uncertainty, increase efficiency and mitigate risks

Honeywell has announced new capabilities that further improve integration and security, and enable compliant, reliable and accurate tank inventory operations for oil storage terminal operations.

Built on the proven Experion advanced automation platform, the ENTIS Inventory System uses the latest tank management and custody transfer technologies to reduce inventory uncertainty, increase efficiency and mitigate risks. Designed for intuitive and easy-to-use operations, ENTIS helps operators manage against product losses and focus on safety.

The new capabilities of the ENTIS inventory system include:

• Real-time visualisation of tank inventory calculations in compliance with the American Petroleum Institute (API) and the American Society of Testing and Materials (ASTM).

• Legal metrology certification for custody transfer, accounting and reporting.

• Intuitive alarms and event management to protect personnel and assets.

• High availability leveraging redundant Communication Interface Units (CIU) and ENTIS redundancy.

• Real-time and historical trend data enabling operators to check tank usage quickly and easily.

• Customisation of reporting formats, including inventory, tank detail and audit trails

• Automation of routine tasks, such as scheduling gauge commands and reports.

Commenting on the new system, Bob Ell, Global Marketing Director, Oil and Gas, Honeywell Process Solutions, says: "Unlike traditional tank inventory systems, which are complicated to operate, difficult to integrate and non-redundant, ENTIS has long served as the class benchmark for tank inventory systems, helping users reduce costs, increase efficiency and improve profitability."

"These upgrades provide versatility for refining, terminal operators, including chemical companies that require accurate, compliant inventory data to run their tank farms not only safely but also efficiently."

Users also gain a variety of safety and productivity benefits from the Experion platform on which ENTIS resides. These include the integration of Honeywell video surveillance and fire and gas systems for tank farms and terminals; a powerful, intuitive operator interface that supports ASM Consortium guidelines; and the capability to build custom displays using Honeywell’s state-of-the-art HMIWeb display builder.

Also, ENTIS offers secure remote monitoring capabilities with a subscription-based business model which enables access to tank gauging information anytime, everywhere.

Developed with more than half a century’s experience in tank gauging and inventory management, the ENTIS Inventory System is one of the most trusted industry solutions, with over 2,000 installations globally. Powerful, modular and easy to use, it provides accurate, secure inventory data, avoids overfills, facilitates leak detection, and helps prevent disasters, protecting people and the environment. ENTIS is suitable for all types of distribution and bulk terminals.

Honeywell is a Fortune 100 technology company that delivers industry-specific solutions that include aerospace products and services; control technologies for buildings and industry; and performance materials globally.

Honeywell Process Solutions is a pioneer in automation control, instrumentation and services for the oil and gas; refining; energy; pulp and paper; industrial power generation; chemicals and petrochemicals; biofuels; life sciences; and metals, minerals and mining industries.

The company is a leader in providing software solutions and instrumentation that help manufacturers find value and competitive advantage in through Honeywell Connected Plant, Honeywell’s Industrial Internet of Things (IIoT) solution.

Process Solutions is part of Honeywell’s Performance Materials and Technologies strategic business group, which also includes Honeywell UOP, a leading international supplier and licensor of process technology, catalysts, adsorbents, equipment, and consulting services to the petroleum refining, petrochemical, and gas processing industries.