Aker Solutions will deliver 22 km of dynamic steel-tube umbilicals and distribution equipment

Aker Solutions will deliver 22 km of dynamic steel-tube umbilicals and distribution equipment

Aker Solutions has been contracted by Subsea 7 to deliver umbilicals to the King’s Quay company for the latter’s development in the deepwater US Gulf of Mexico.

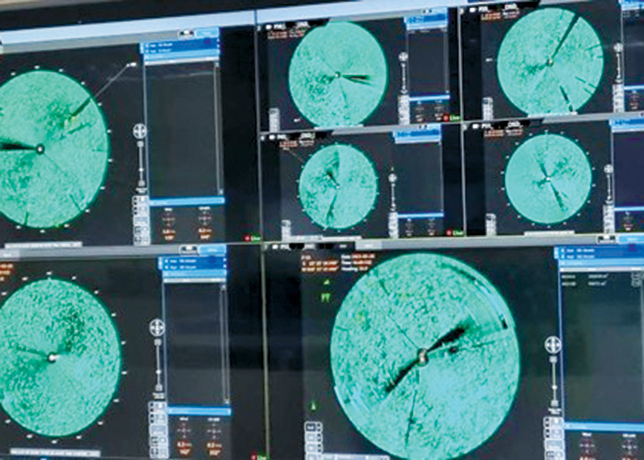

The work scope includes 22 km of dynamic steel-tube umbilicals and distribution equipment to connect the King’s Quay floating production system (FPS) to the Samurai, Khaleesi and Mormont deepwater developments.

The King's Quay semisubmersible FPS will be about 280 km south of New Orleans in the Green Canyon area.

The engineering, design, and manufacturing of the umbilicals and distribution equipment will take place at the company’s facility in Mobile, Alabama. Work starts immediately and the delivery is planned for 4Q 2021.

In another order, Aker Solutions and Norcem have signed an engineering, procurement and construction (EPC) agreement for delivery of a CO2 capture, liquification and intermediate storage plant at Norcem’s cement factory in Brevik, Norway.

The plant is part of the Norwegian carbon capture demonstration project and funded by the Norwegian government.

The 400,000 metric tons of captured CO2 from Norcem Brevik annually will be transported to the Northern Lights project for permanent storage.

Aker Solutions and Norcem continue to work closely on the project to prepare for the EPC phase. The project will use Aker Solutions’ Advanced Carbon Capture (ACC) technology and its HSE-friendly S26 amine solvent.

"We are excited to take another important step towards realizing the first industry-scale carbon capture plant at a cement production facility anywhere in the world, and a major EPC project for Aker Solutions," says Knut Nyborg, Executive Vice President, Front End, at Aker Solutions.

"Carbon capture, utilisation and storage will play a big part in cutting European CO2 emissions, and is an important segment in our 20/25/30 strategy."

Aker Solutions aims to generate 20 per cent of its revenue from renewables and 25 per cent from low-carbon solutions by 2030.