Alimak Hek ... providing a total elevator package

Alimak Hek ... providing a total elevator package

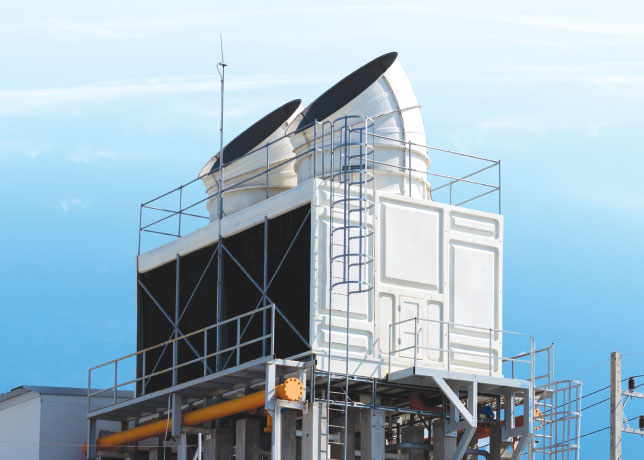

The Alimak Hek Group specialises in rack and pinion-driven elevators for industrial locations and has more than 40 years' experience in oil and gas applications. The elevators, which are available in explosion protected designs, provide reliable and convenient access in oil refineries, natural gas processing plants, petrochemical plants, LNG storage tanks as well as derricks, hull columns and platform modules of offshore platforms.

The product range includes Alimak elevators. The modular-built elevators are adaptable in size and capacity and do not need a machine room or elevator shaft. Alimak Hek provides a total elevator package from concept design and construction to comprehensive through-life after-sales support globally.

Alimak Hek has been supplying rack and pinion elevators to the oil and gas industry since 1974 when the first offshore elevator was installed on a semi-submersible platform in the North Sea. So far, more than 1,000 Alimak oil and gas elevators have been delivered worldwide. The elevators complement potentially hazardous stairways, ladders and cranes to provide convenient access to process critical areas for people and material.

Reducing Cost and Time

Loss of production due to unplanned as well as planned maintenance stops, is becoming more and more expensive. Many field studies have shown that the installation and usage of Alimak rack and pinion elevators is extremely profitable, says a company spokesperson. Even for very low lifting heights, the break-even point to invest in an Alimak elevator compared to staircase is reached very quickly, he adds.

Elevator Design

Alimak elevators are based on a modular design enabling specific customer requirements to be met with proven standard components. The system provides a variable range of lifting heights, car sizes and capacities capable of meeting the most stringent specifications. The elevator car and drive system are completely assembled and tested at the factory before delivery which ensures fast installation at the jobsite. The modular Alimak passenger and freight elevator range is designed for endurance and functioning in any type of industrial environment, no matter climate, the spokesperson explains.

Alimak rack and pinion elevators are: made for tough environments; no elevator-shaft needed; no separate machine room; simple and cost efficient installation; easy to install to almost any structure; small footprint; can be installed on inclined and curved surfaces; indoor or outdoor installation; durable and easy to service and maintain; explosion protected elevators for hazardous areas; operation not affected by rolls, pitches or heaves and easy to retrofit to existing structures.

Their payload capacity is 300 kg – 12,000 kg; travelling speed is up to 1 m per second; lifting height up to 250 m (increased lifting height on request) and ex standard version available in protection class Atex: Zone 1 or 2, Gas group I, IIA or IIB, Temp class T1–T3 (T4); protection class NEC: class 1, division 2, Gas group C or D, Temp class T1–T3 (T4) and dust, NEC: class 2, division 2, Dust group F.

Easy to Retrofit to Existing Structures

Alimak elevators can easily be installed on any structure and are ideal for retrofitting on existing oil-rigs that are undergoing upgrading, or retrofitted in existing refineries or petrochemical plants. It has actively been involved in a wide range of modernisation projects.

Quality Conscious

Alimak industrial elevators are produced in Skellefteå, Sweden. Quality has always been the hallmark of Alimak and Hek rack and pinion products. In 1993, the manufacturing units in the Alimak Hek Group received the ISO 9001 quality certification for design, development, manufacturing and service.

“Since then we have integrated and enhanced the certification demands into the way we work, also encompassing our suppliers. This means that we meet and exceed the high demands raised in special projects, many times verified by independent bodies such as Lloyds, DNV and ABS,” says the spokesperson.

“We are committed to providing rack and pinion solutions to be used in the harshest and most hostile environments, where quality is a necessity. Nothing leaves the factories without the required testing. All critical components are subject to wear and tear testing. For example, all Alimak over-speed safety devices (the most vital safety component) are verified in specially designed testing facilities prior to delivery,” he adds.

Alimak Hek engineers have long and vast experience from projects with high demands and are able to handle special project through all stages. They are trained and organised to provide project plans and risk analyses, carry through approval and inspection procedures and deliver correct, complete documentation on time.

Worldwide Organisation

Alimak rack and pinion elevators are provided through a worldwide network of Alimak Hek sales companies and distributors. Local service and support is provided in more than 60 countries around the world. This means easy access to support, spare parts and skilled service technicians at nearby locations.