When Jasmine Water and Beverages Factory, a large water and beverage factory based 120 km west from Riyadh city, needed a reliable and uninterrupted power supply for its 24/7 operations, it turned to Atlas Copco’s partner GCC Olayan for a solution.

Jasmine Water and Beverages Factory’s plant is in a remote location in the desert, without access to stable power grid. Therefore, the company was facing frequent power failures, making the continuous production line difficult. That is why Jasmine Water and Beverages required a reliable generator.

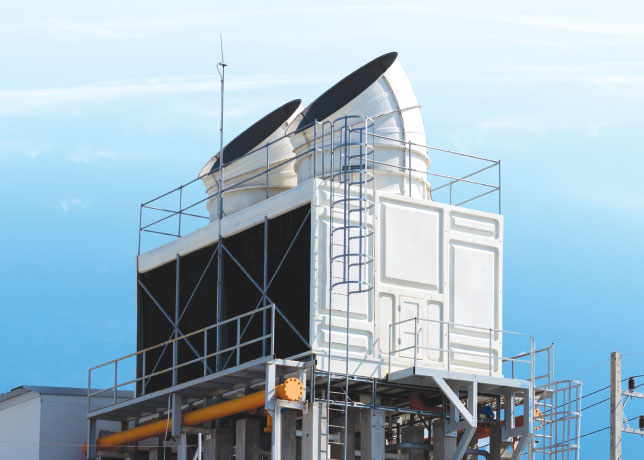

To overcome the challenge, GCC Olayan, Atlas Copco Power and Flow’s official distributor in Saudi Arabia recommended four TwinPower generators. The TwinPower from Atlas Copco is a unique containerised portable generator that delivers unrivalled versatility, fuel economy, and twice the amount of on-site power than conventional Independent Power Plants (IPPS).

Atlas Copco TwinPower is a 20-ft ISO containerised unit housing two compact 500-kVA generators; powered by compact Scania engines. This configuration, with an advanced control system, allows the two generators to work independently or in parallel with each other. This makes it ideally suited for applications that have variable power needs, whether due to the time of day or the current usage requirement.

“The QAC 1100 TwinPower is perfect for applications that require intensive use because it delivers high performance while maximising fuel efficiency, cutting associated running costs, and low-cost of ownership, amongst other benefits. Also, thanks to its flexible design of two generators in one platform, it gives our client flexibility and the QAC 1100 generator works in the harshest conditions, such as a very hot climate in a Saudi desert,” explained Ahmed Badawi, Regional Sales and Marketing Manager – Power and Light.

Jasmine Water and Beverages Factory needed 4,000 kVA to work in synchronisation, that is, working together and not as separate units. As a solution, Atlas Copco modified the totalization and distribution panel and fuel systems of the TwinPower units.

To ensure the best fuel optimisation, Atlas Copco recommended using the PMS (Power Management System) mode. The TwinPower is equipped with a centralised control and monitoring system that is both easy-to-use and configure. This is facilitated by two Qc4003 digital controllers that feature intuitive touchscreens, and a choice of island or PMS (Power Management System) modes.

“We are very pleased with the Atlas Copco QAC 1100 TwinPower. It provides us with the reliable power supply that our production line needed to run 24/7 without cuts while offering us the best fuel optimisation for our plant,” stated Ashraf El-Nahas, Factory General Manager - Jasmine Water and Beverages Factory,’

“We highly recommend working with GCC Olayan and Atlas Copco because all the projects have run smoothly and in a timely manner,” concluded El-Nahas.

Atlas Copco TwinPower is designed for easy service. Large access doors and custom service tools make for effortless maintenance and assured uptime. The positioning of the motor and alternator sets on opposite sides enable multiple access points to all the main components.

Eng Ibrahim Nazih, Atlas Copco division manager- GCC Olayan commented: “We are delighted Jasmine Water and Beverages Factory Ltd Co trusted us with this project, and we look forward to continuing working with them via our service package.” –Tradearabia News Service