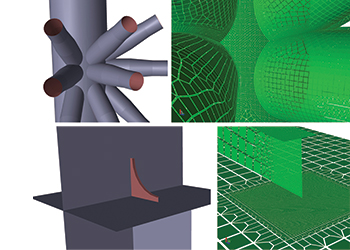

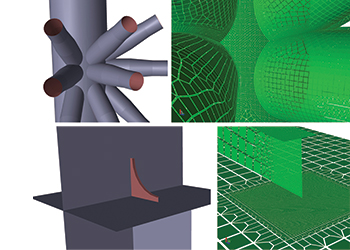

DNV tubular joint (top) and coarse bracket model

DNV tubular joint (top) and coarse bracket model

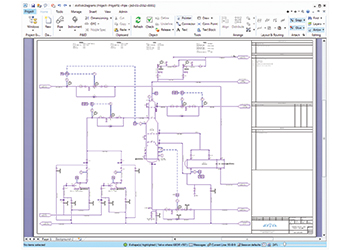

With energy prices under pressure, the oil and gas industry is looking for new ways to improve engineering efficiency. DNV GL says its new Sesam GeniE 7 release saves significant time and cost with its new meshing capabilities, a breakthrough in engineering software for offshore and ship structures.

When engineers use the finite element method (FEM) to calculate the strength needed for offshore and ship structures to withstand forces such as wind and waves, optimal results are dependent on creating an accurate mesh representation in a 3D model. This has been a time-consuming operation when implementing design changes. With the new Sesam GeniE, engineers can save significant time and gain accuracy in their results using partial meshing.

The new meshing features of Sesam GeniE can be used on floating and fixed structures for all types of linear analysis. "This will help users save significant meshing time during re-meshing after a change in structure or mesh settings," says Ole Jan Nekstad, Sesam product director at DNV GL - Software, who is currently training Sesam users all over the world to use the new features.

Engineers now have control of the mesh, and are able to gain high precision by manually changing it and refining the grid. They can edit node positions while moving, collapsing or deleting elements, while continuously getting feedback on the mesh quality. For analysis of jackets and topsides, partial meshing leads to a constant finite element numbering system that saves time for re-meshing. "The response out in the field has been great," says Nekstad. "When I show people what Sesam GeniE can do now, they’re amazed."

In addition, the new Sesam GeniE 7 can make automatic reports that include pictures of the structure, the finite element model and results. The pictures are automatically generated using view angles chosen by the users. "Many man-hours can be saved since it is not necessary to manually cut and paste pictures into a report," says Nekstad.