The new generation AmaDrainer 3 submersible grey water pumps

The new generation AmaDrainer 3 submersible grey water pumps

The AmaDrainer 3 type series is very robust and offers a high operating reliability, while a new hardware addition to KSB Guard monitoring system allows pumps for use in potentially explosive Zone 1 areas

The KSB Group has launched the youngest generation of its time-tested submersible grey water pumps on the market: the AmaDrainer 3 type series.

The new development of these pumps, available in four sizes, is the manufacturer's response to customer requests for a design that is more compact and easy to handle.

Its compact design, integrated float switch, and a diameter of no more than 155 mm make the type series suitable for narrow spaces such as light wells, for example. The maximum head is 11.3 m.

"The submersible motor pumps are very robust and provide a high operating reliability. All four sizes are designed for continuous duty at a fluid temperature of up to 70 deg C and briefly even up to 90 deg C," says a company spokesman.

A novelty is the integrated low water level intake: By removing the suction strainer the two smaller pump sizes can achieve residual water levels as low as 2 mm. The larger pump sizes are characterised by free passages of up to 35 mm, so they can also transport coarse matter contained in the waste water. For aggressive water and other fluids handled, a special variant is available for all sizes.

All pump sets feature a high-quality plastic casing. They are low in weight and highly corrosion-resistant. A jacket-cooled motor permits operation even when the motor is not submerged.

In addition, AmaDrainer 3 comes with integrated motor protection. Fitted with a 10-m power cable as standard, the pump set allows for more flexible handling.

The new submersible grey water pumps are versatile in use. They can be used for draining shafts and cellar rooms as well as for extracting water from reservoirs and rivers, for emergency drainage and other applications such as draining outside basement stairwells and underground passages. The pump sets are supplied ready to be plugged in, enabling fast installation and commissioning.

EXPLOSION-PROOF SOLUTIONS

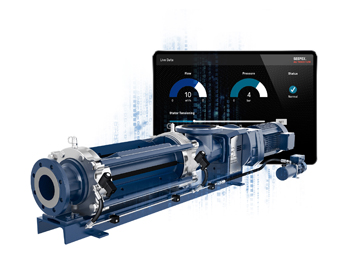

KSB offers smart monitoring solutions for pumps and other rotating equipment used in potentially explosive atmospheres

Over the last two years, KSB has developed a wide range of solutions to ensure pumps are ready for the digital age, including the product portfolio for the KSB Guard monitoring solution. Both the KSB Guard data interface and the KSB Guard monitoring service were launched on the market with great success and have proven their effectiveness in countless applications.

The company has now added a new hardware version to the solution for use in potentially explosive atmospheres (ATEX zone 1 with gas atmosphere).

The KSB Guard smart monitoring solution is designed for monitoring already installed pumps and is thus ideal for retrofitting – regardless of pump make.

A sensor unit, comprising a vibration sensor and a temperature sensor, attached to the pump’s bearing bracket and/or drive lantern or to other rotating equipment records the relevant data.

The transmission and battery unit wirelessly transmits the measurement data to a gateway which, in turn, transfers the data via encrypted mobile communication to the KSB Cloud. This is where the data is evaluated and processed. The user can then view the information in the KSB Guard app and on the KSB Guard web portal.

A brand new feature of the KSB Guard solution is the use of ATEX-certified hardware. The KSB Guard ATEX gateway is supplied in a flameproof enclosure. The external antennas can be screwed on directly or positioned elsewhere via an extension cable if necessary.

The KSB Guard ATEX sensor unit and KSB Guard ATEX transmission and battery unit are intrinsically safe (Ex-i). Both solutions are also suitable for outdoor installation thanks to robust lithium thionyl chloride batteries with a service life of 5 to 8 years in conjunction with 60-minute measurement intervals.

Users of the KSB Guard solution benefit from higher operating reliability and transparency, for example by being notified whenever limit values are exceeded.

Thanks to trend analyses, impending damage can be detected at an early stage and prevented. The measured data can be viewed via the web portal or the app anytime, anywhere, enabling maintenance work to be better planned.

As well as making it easy for users to change from reactive to proactive maintenance, the solution also helps to identify potential energy savings.

KSB Guard paves the way for the world of Industry 4.0 which is based on innovative technologies such as artificial intelligence and machine learning. A data science team ensures that the algorithms in the KSB Cloud and the data evaluation are continuously optimised.