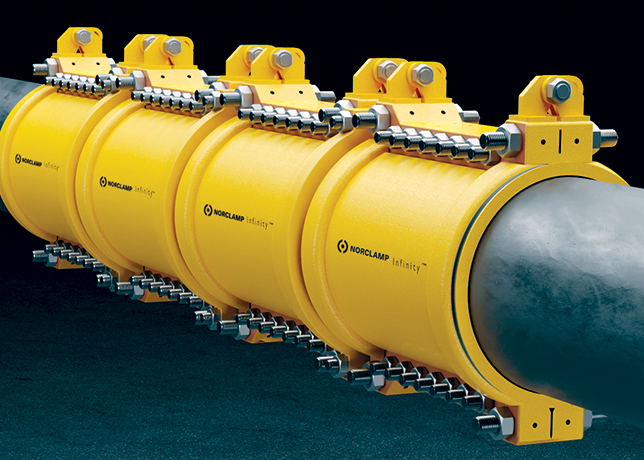

Norclamp’s infinity clamp is positioned over the damaged area, ready to be installed

Norclamp’s infinity clamp is positioned over the damaged area, ready to be installed

Norclamp’s sustainability initiatives show how businesses can turn this challenge into an advantage, finding opportunities to save money and enhance operations while reducing emissions

In the oil and gas industry, where public scrutiny and environmental regulations are intensifying, impactful sustainability initiatives are increasingly becoming critical to long-term success.

Operators face growing pressure from investors and stakeholders alike to reduce greenhouse gas emissions, minimise waste, and preserve natural resources.

Every link in the supply chain contributes to the oil and gas sector’s environmental footprint, from the energy-intensive processes of steel production to the logistics of transporting materials and maintaining infrastructure.

For technology companies, this means prioritising low-emission materials and optimising production processes to ensure they are still seen as preferred suppliers.

For service providers, it means developing solutions that extend the life of existing infrastructure, reducing the need for costly and resource-intensive replacements.

Together, these efforts can lead to significant cost savings, operational efficiencies, and enhanced reputational value.

In a pioneering pilot project, Terravera Foundation, a leading partner in third-party documentation of sustainability data, has demonstrated that it is possible to deliver both environmental and commercial gains in the oil and gas service sector.

This project proved this was possible by making strategic changes to the production process.

This industry-first project was undertaken in partnership with Norclamp, a specialist in standardised clamps, and ClimateAdvisor.

Norclamp’s sustainability initiatives show how businesses can turn this challenge into an advantage, finding opportunities to save money and enhance operations while reducing emissions.

Norclamp’s real breakthrough lies in how the company transformed its production process–cutting emissions and costs by rethinking how they source materials and manage resources.

It’s a clear example of how sustainability measures can drive both environmental progress and financial success.

SUSTAINABILITY IN PRACTICE

Steel production, a cornerstone of the industrial supply chain, is also one of its largest contributors to carbon emissions.

|

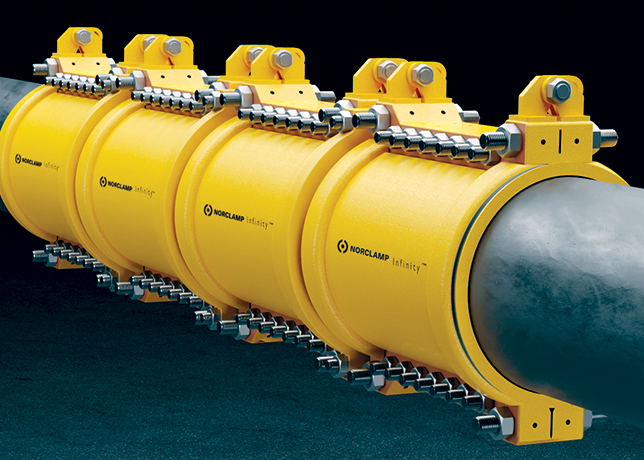

Four infinity clamps are now installed and sealed together to cover corrosion |

For Norclamp, as their clamps are built from steel, addressing this challenge meant not just tweaking its processes but rethinking its approach.

By optimising material usage, Norclamp achieved a 26 per cent reduction in steel-related emissions.

This change not only reduced the company’s carbon footprint but also slashed production costs by 27 per cent.

The pilot project spearheaded by the Terravera Foundation exemplifies how targeted sustainability efforts can yield significant results.

Terravera, known for its expertise in third-party documentation of sustainability data, collaborated with Norclamp to analyse the environmental impact of Norclamp’s production processes.

The initiative began with Terravera’s modelling team collecting and verifying detailed production data.

Using a digital value chain model, they simulated potential improvements to identify emissions hotspots and efficiency opportunities.

Their analysis revealed that steel production accounted for the vast majority of emissions.

Armed with this insight, Norclamp implemented strategic changes that dramatically reduced both emissions and costs.

'This project is a testament to Terravera’s commitment to empowering data-driven sustainability decisions for organisations,' says Elisabeth Kjerstad Boe, CEO of the Terravera Foundation.

'By verifying emissions data, we provided Norclamp with actionable insights to guide their sustainability strategy.'

BEYOND COMPLIANCE: SETTING NEW STANDARDS

One of the most striking aspects of this pilot project is how it goes beyond the EU’s CSRD regulations that will come into force in 2025.

Norclamp’s proactive approach–validating its value chain two years ahead of regulatory requirements–demonstrates its commitment to leadership in sustainability.

'Connecting verified emissions data to financial metrics ensures that sustainability efforts also bring commercial benefits,' explains Kristin Hidle Vinje, CEO of ClimateAdvisor.

'This project exemplifies how companies can meet emerging standards while simultaneously driving business value.'

The results achieved by Norclamp and its partners underscore the importance of integrating sustainability into business strategies.

By taking a data-driven approach, the company has not only reduced emissions and costs but also positioned itself as a pioneer in sustainable practices within the oil and gas service sector.

'This pilot project represents a significant step toward more sustainable production in the oil and gas industry,' says Adrian Gamman, Chairman of the Board at Norclamp.

'It sets a new standard for how data-driven sustainability models can yield measurable results.'

By focusing on actionable data, companies can make strategic changes that reduce emissions, cut costs, and enhance operational efficiency. These efforts not only meet the demands of stakeholders and regulators but also create long-term value for businesses.

THE BIGGER PICTURE

|

A corroding pipe with a leak in need pf repair |

Furthermore, the global shift to cleaner energy is transforming the oil and gas industry in several ways, one being a prompt to find innovative uses for existing infrastructure and prolonging its lifespan.

Maximising the use of existing infrastructure like pipelines often proves more advantageous than starting from scratch.

It reduces costs, saves time, and minimises environmental impacts, all while aligning with sustainability goals.

As pipelines age, they face a convergence of risks. Corrosion is one of the most pervasive issues caused by a combination of environmental exposure, the chemical composition of transported materials, and physical wear.

Corrosion not only weakens pipelines but also increases the likelihood of leaks and ruptures–events that can devastate ecosystems and contaminate water supplies, while emissions from compromised infrastructure undermine global decarbonisation goals.

For operators, the financial impact is also significant, as repairs, regulatory penalties, and the risk of reputational damage all add up.

Yet, despite these challenges, pipelines remain indispensable. Global energy demand continues to grow in parallel with population increases and industrial expansion.

Meeting this demand while managing the risks of aging infrastructure requires a dual focus on innovative solutions and sustainability.

One such innovation, Norclamp’s Infinity Clamp, represents a breakthrough in how operators can maintain and repair aging pipelines efficiently and sustainably.

The Infinity Clamp is more than just a practical tool. By enabling targeted repairs, it reduces the need for full-scale replacements, saving operators millions in capital expenditures.

Its rapid deployment minimises production downtime, ensuring that pipelines can return to service quickly and efficiently. In addition, Norclamp’s commitment to sustainability further enhances the clamp’s value.

EXCEEDING EXPECTATIONS

'We are proud to embed sustainability into our operations, and the results have exceeded our expectations,' says Gamman.

By extending the life of pipelines, Norclamp contributes to the industry’s alignment with global net-zero goals, proving that sustainability is not just an ethical imperative but also a practical business strategy.

Looking ahead, Norclamp plans to build on the success of this pilot project by embedding sustainability even further into its processes and operations.

With a clear roadmap in hand, the company is well-positioned to lead the charge toward a greener, more efficient industry.

The Infinity Clamp and the broader sustainability initiatives undertaken by Norclamp and its partners offer a compelling case study of the power of innovation and data-driven decision-making.

By tackling emissions at their source and rethinking traditional production methods, Norclamp has demonstrated that environmental and commercial goals are not mutually exclusive.

This pilot project represents a significant step toward more sustainable production in the oil and gas industry and sets a new standard for how data-driven sustainability models can yield measurable results in both emissions reduction and cost savings.

As industries worldwide grapple with the realities of climate change, this project serves as a reminder that sustainability audits are not just tools for compliance but pathways to transformative change.

For industries like oil and gas, the transition to sustainable practices is both a challenge and an opportunity.

Companies must balance the immediate demands of maintaining operations with the long-term need to reduce their environmental impact. Norclamp’s success highlights the potential of sustainability audits to uncover areas of inefficiency and drive meaningful change.

By Abdulaziz Khattak