Intertek ... managing assets effectively

Intertek ... managing assets effectively

INSPECTION is integral to maintaining and protecting the operational integrity of facilities and assets in the oil and gas industry. Intertek is a global leader in inspecting complex equipment with its extensive experience and technical resources, and can help companies effectively manage their assets in order to gain maximum value.

Its strong presence in the Middle East means it has worked with many of the region’s major oil and gas suppliers. It understands how failure in equipment and unplanned shutdowns impacts safety, production levels and revenue, and why obtaining the right inspection capabilities can help firms avoid this.

So whether companies operate upstream, mid-stream or downstream, Intertek’s world class services in non-destructive testing (NDT) and risk-based inspection (RBI) can help them to manage the risk of asset failure. Other complementary services provided include erosion, corrosion and coating inspection and vendor inspection. Intertek has supported many major projects and operating plants throughout the Middle East, and recent work has included a piping integrity survey that required NDT, American Petroleum Institute (API) engineers and risk-based inspection, plus a long-term shutdown assignment.

Roger Kay, general manager, Intertek Inspec, says: “The demand for non-destructive testing has grown due to increased regulation and the need to extend asset lifespan. We can help our customers meet these challenges both onshore and offshore, and especially in fabrication yards for oil and gas rig construction.”

NDT encompasses a wide group of analysis techniques that do not permanently alter or damage the item being assessed. NDT techniques help assure safety and reliability through detection of any defects in industrial assets such as piping, pressure values and tank floors. It is a highly valuable technique that can save both time and money in asset evaluation. Intertek’s NDT techniques include, but are not limited to: radiography; ultrasonic testing; phased array; dye penetrant inspection; positive material identification; magnetic particle inspection; gamma ray radiographic testing; ferrite testing; rope access; and hardness testing.

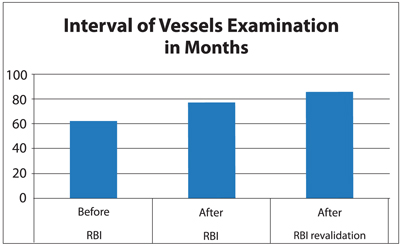

In addition, the company works with customers to implement risk-based inspections, an approach that minimises downtime and ensures equipment longevity. The methodology can evaluate both the likelihood and consequences of failure in assets, and provide the information needed to determine how often inspections should take place and the appropriate and cost-effective inspection techniques to use. By partnering with Intertek, it can help companies achieve their goals for asset integrity, safety, quality and performance. Discover the difference its NDT and inspection services, experience, knowledge and cutting-edge technology can make.