Cortec's guide will help rig operators avoid loss from equipment corrosion during extended shutdown

Cortec's guide will help rig operators avoid loss from equipment corrosion during extended shutdown

With the major shocks the oil and gas industry has experienced in recent months, today’s rig count is significantly lower than last year. Land-based oil drilling rigs are typically the first to be affected and shut down during market lows, leaving operators in critical need of practical solutions for preservation.

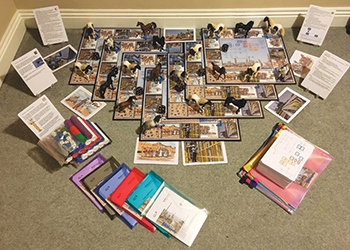

To help rig operators avoid loss from equipment corrosion during extended shutdown, Cortec Corporation has published a detailed guide to ‘Layup of Land Based Drilling Rigs’. The guide offers step by step instructions using preservation materials that in many cases do not require extensive removal prior to startup, simplifying preservation and minimizing or eliminating disposal concerns.

The layup guide goes into detail about how to use VpCI Technology to protect mud pumps and boilers, top drives and draw works, different sizes of HPUs and electricals/electronics, and much more. These include diesel engines, roughnecks, hydraulic catwalks, AC traction motors, VFD and MCC Houses, mud pits, water tanks, choke manifolds and gas busters, air compressors, drill pipes, and winches.

Recommended protective materials include Cortec oil additives, VpCI Emitters, VpCI-126 HP UV Shrink Film or MilCorr VpCI Shrink Film, VpCI-649, and VpCI-337.

CorrLube VpCI Lithium EP Grease serves as an all-purpose corrosion inhibiting lubricant for the many grease purge points found on equipment, while CorShield VpCI-369 is a versatile wet-film corrosion inhibitor that can be used on a variety of connectors or moving components.

One common strategy outlined in Cortec’s land rig layup guide is to spray ElectriCorr VpCI-239 inside electrical/electronic enclosures and apply VpCI-105 Emitters, VpCI-111 Emitters, or VpCI-308 Pouches according to the space’s volume. These materials are useful for protecting the many sensitive and critical components such as computers, touch screen HMIs, battery packs, and AC drives found on a drilling rig. Products are extremely easy to remove at startup, if they need to be removed at all, and some may continue to be used for corrosion protection during operation.

For the pervasive lube, oil, and gear systems of drill rig equipment, the guide repeatedly references Cortec’s range of corrosion inhibiting additives for compatibility with different oil types: PAG, PAO, or mineral-oil based. These additives play an important role in effective preservation for hidden but critical systems and can be easily removed if required. Other corrosion-inhibiting additives, coatings, or injectable products listed in the guide address the needs of cooling systems, fuel systems, and both insulated and non-insulated piping on a drilling rig.

For anyone who finds themselves in a time of crisis in the oil and gas industry, wondering what to do next and how to protect assets in the meantime, this guide will be an important tool to successful asset value preservation amidst uncertainty.

Cortec Corporation is the global leader in innovative, environmentally responsible VpCI and MCI corrosion control technologies for the packaging, metalworking, construction, electronics, water treatment, oil and gas, and other industries. Headquartered in St Paul, Minnesota, Cortec manufactures over 400 products distributed worldwide, and is ISO 9001, ISO 14001:2004, and ISO 17025 certified.