The first semi-finished part made of Ultramid Advanced N

The first semi-finished part made of Ultramid Advanced N

The Ultramid Advanced N is a suitable material for extruding pre-fabricated components and small assemblies with many applications in the automotive industry, mechanical engineering and kitchen appliances

BASF has developed Ultramid Advanced N5H UN, a polyphthalamide (PPA) that can be manufactured into semi-finished parts by extrusion.

Ultramid Advanced N offers excellent mechanics at elevated temperatures due to its semi-aromatic chemical structure. It shows excellent resistance to chemicals and hydrolysis, even in aggressive environments, as well as good sliding friction properties – and all this at temperatures above 100 deg C.

Due to its low water uptake its mechanical properties remain stable over a wide temperature range. Even in humid environments, the long-chain high-performance material shows a dimensional stability that belongs to the highest of all polyamides.

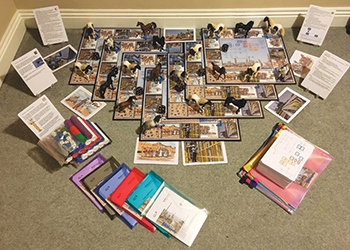

This property profile makes Ultramid Advanced N the perfect material for extruding pre-fabricated components and small assemblies but also for many applications in the automotive industry, in mechanical engineering and in kitchen appliances. During machining, the behavior of the semi-finished products lies between a polyamide and a polyoxymethylene copolymer, with steady and consistent chip formation and removal.

German plastics company GEHR is using the new PPA to produce extruded stock shapes with a diameter of 50 mm.

"GEHR is the first company to successfully use a PPA for extrusion. With its expertise in extrusion, GEHR has developed stock shapes that can be produced without any voids," says Philipp Wenz, Group Head in Sales of BASF’s Performance Materials division.

"We can't say for certain whether it’s the world’s first semi-finished part made from polyphthalamide. The high-performance material has definitely not yet played an important role in the market for semi-finished parts. One reason for this might be that usual polyphthalamides cannot be extruded very well."

Thus Ultramid Advanced N5H closes a gap in the market between semi-finished parts made of polyetheretherketones and polyarylsulfones on the one hand and semi-finished products made from engineering plastics on the other hand. In comparison to the latter it can be used at continuous operating temperatures well above 120 deg C. The BASF material is also suitable for profiles other than rods.

Bernhard Grosskinsky, Head of Application Technology at GEHR, explains: "BASF’s polyphthalamide is far easier to process compared to other PPAs on the market. It gives us a wide processing window with at the same time a high melt stability. The quality of the material always remains the same so that we can maintain a stable production of our semi-finished parts. Last but not least, another advantage of BASF’s PPA: It is easy to produce finished components from the semi-finished products by post-processing."

A wide range of applications can be manufactured from GEHR’s extruded rods: Components with very high operating temperatures and pump parts requiring exact dimensional stability are just as feasible as gear wheels, thermostat housings and sliding rails. In the automotive industry, the material is particularly suitable for components that come into contact with motor and transmission oils, coolants, acids, salts and de-icing fluids. Parts that require high sliding friction properties can be used even at high temperatures due to the material’s high impact resistance and very low wear rate.

BASF’s PPA portfolio is based on the four polymers Ultramid Advanced N (PA9T), Ultramid Advanced T1000 (PA6T/6I), Ultramid Advanced T2000 (PA6T/66), and the long-standing Ultramid T KR (PA6T/6). They open the door to the next generation of lightweight, high-performance plastic components in many different sectors including the automotive industry, electronics and electric devices, mechanical engineering and consumer goods.

The PPA portfolio is available globally and complemented by BASF’s Ultrasim simulation tool and extensive experience in application development. It includes more than 50 compounded grades for injection molding and extrusion, products with or without flame retardants. The compounds are available in different colors, from colorless to laser-markable black, with short-glass, long-glass or carbon fiber reinforcement, and with various heat stabilizers.

BASF’s Performance Materials division encompasses the entire materials’ know-how of BASF regarding innovative, customised plastics under one roof. Globally active in four major industry sectors – transportation, construction, industrial applications and consumer goods – the division has a strong portfolio of products and services combined with deep understanding of application-oriented system solutions. In 2019, the Performance Materials division achieved global sales of €6.06 billion ($6.81 billion).

BASF’s portfolio is organised into six segments: Chemicals, Materials, Industrial Solutions, Surface Technologies, Nutrition & Care and Agricultural Solutions. In 2019, the company generated sales of €59 billion.