Actuators provide a viable solution for safety, positioning and diagnosis

Actuators provide a viable solution for safety, positioning and diagnosis

Actuators used in oil and gas have to withstand rigorous conditions like extreme temperatures, corrosive effects of chemicals, and explosive atmospheres for extended periods

The oil and gas industry relies heavily on automated flow and motion control mechanisms, be it upstream, midstream, or downstream applications. The device which makes this possible is the ‘actuator’.

These devices support a variety of mining and oil and gas applications and provide a viable solution for safety, positioning, diagnosis, and many other requirements.

HOW DO ACTUATORS WORK

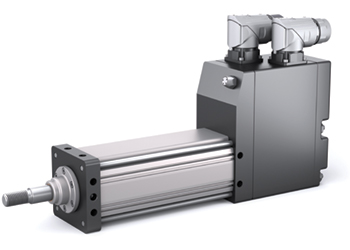

In simple words, an actuator is a part of a machine that converts energy into torque, which further moves or controls a system. This process is initiated after the actuator receives a command from a control signal.

To manage long distances between devices, data transmission via optical fibre is a viable solution.

After transferring the control signal, a source of energy is provided to the actuator. This helps the actuator to introduce motion as well as control it (Figure1).

MOTION OF ACTUATORS

The actuators can produce movement within a straight line back and forth, called linear motion; and can also make circular motion, called rotary motion.

Linear actuators facilitate reliable, secure, and accurate mobility, mainly when operators use them in combination with sensors.

This aids in accomplishing monotonous tasks with negligible manual involvement.

Since, liner motion (both vertical and horizontal) is the most-widely performed application across industries, linear actuators are in high demand.

Different types of actuators can be sorted according to the power source or system they use. Some common types of actuators according to energy source include:

• Hydraulic actuators: These operate by using a fluid-filled cylinder. Commonly, these actuators produce linear movements widely seen in exercise equipment, transport carriers, etc.

|

Figure1 … Functional diagram of the actuator |

• Pneumatic actuators: These actuators work by using pressurised gases to create movement. Companies that use machines where drives have to convert inflowing gas or liquid’s pressure into a rotary motion, use pneumatic actuators, such as vehicle brakes, vane motors, pressure sensors, pneumatic mailing systems, etc.

• Electric actuators: As the name suggests, these actuators require an electricity source to operate. Some common examples include electric cars, manufacturing machinery, and robotics equipment, etc. There are a few types of electrical actuators including electromechanical actuators, which convert electric signals into rotary or linear movements or a combination of both; and electrohydraulic actuators, which are powered electrically but give movement to hydraulic energy storage devices/ accumulators.

• Thermal actuators: These actuators use thermally-induced expansion and contraction of materials as a mechanism for the creation of motion. Typical thermostatic actuators consist of a temperature-sensors that convert thermal energy into kinetic energy, or motion.

• Magnetic actuators: Most magnetic actuators can produce a wide and powerful range of motion while remaining lightweight. These actuators use magnetic effects to generate forces that impact the motion of a part in the actuator.

• Mechanical actuators: Rack and pinion systems are some examples of these kind of actuators. Rack and pinion system is widely used component in railways and consists of a pinion/circular gear with a rack/linear gear. Mechanical actuators work by converting a revolving motion (via gears) into linear motion.

Out of the aforementioned types, electric actuators are the most-preferred across industries, owing to their multiple benefits including precision, scalability, customisation, and cost-control.

APPLICATIONS OF ACTUATORS IN O&G

The oil and gas industry holds just a small share of the actuators market globally. However, they are used in a wide range of activities in oil and gas, including drilling, extraction, storage, transportation, refining/processing, Inspection procedures, etc.

|

Figure 2 … Global market growth forecast of actuators |

In the upstream segment, actuators are used for the flow of fluids and gases. In the midstream segment, they are used for the storage and transportation of resources. And in the downstream segment, they are used in refining process and distribution of oil and gas to a number of end users.

Actuators used in the oil and gas industry withstand rigorous conditions like extreme temperatures — from drought or high-rainfall environments, remote areas in deserts or the arctic — the corrosive effects of chemicals, explosive atmospheres, etc for extended periods.

ACTUATORS AND METHANE EMISSIONS REDUCTION

The oil and gas industry is currently responsible for about 40 per cent of global methane emissions, says a report of the International Energy Agency (IEA).

In this industry, methane (CH4) is one of the key greenhouse gases with a higher impact on global warming than CO2.

Over 100 countries including the US and Canada are supporting the Global Methane Pledge, which aims to reduce global methane emissions by, at least, 30 per cent from the 2020 levels by 2030. This could reduce over 0.2 deg C warming by 2050.

Actuators have the ability to reduce methane emissions and that helps in maintaining the equipment, saving operator’s return on investment and profits.

APPLICATIONS OTHER THAN O&G

Actuators impact our lives on a daily basis, to the extent we are unaware of. A very basic example is the car we drive.

A modern passenger is equipped with more than 120 motors to control various application, such as seat adjustment, HVAC system, coolant and refrigerant valves, headlight positioning, etc.

With the rise of autonomous vehicles, more and more actuators will play crucial roles in enhancing safety and comfort of the passengers.

The automotive industry is also thus the biggest consumer of actuators, among other numerous applications, catering to nearly half of the worldwide sales of actuators.

Another application, which has found prominence since 2019 is healthcare industry. Raising and lowering the hospital beds, and movements in scanners, laser positioning, hospital lifts, dental chairs, etc, are all controlled by actuators.

Other notable industries that actuators are marine, aerospace, defence, and electronics.

Among all applications, the automotive industry creates nearly half of the above-mentioned demand for actuators worldwide. Figure 2 shows the global market growth estimation of actuators.

In 2021, approximately $55 billion worth of actuators were sold globally. The report on the Global Actuators market suggests that the annual market for actuators will reach $75 billion in 2027, growing annually at 5.2 per cent.

SMART ACTUATORS – THE FUTURE

Getting the most from a motion system means finding the best actuator that works efficiently, and is sturdy and reliable.

An improved version of actuators are ‘smart actuators’.

A smart actuator is an integrated actuator that includes onboard controls, improved communication capabilities, position control and feedback, and fault detection.

These features make the actuator easy to install, use, programme, and monitor while eliminating the need for external controls.

Other innovations and cutting-edge technologies like artificial intelligence (AI), internet of things (IOT), 3D printing, etc, are taking the performance of actuators to the next level.

With the growing demand in the sectors like robotics, medical advancements (prosthetics, etc), actuators are getting a facelift with advancements in their size, durability, intelligence, energy efficiency, and more.

To view full Actuators Market Size, Share, Trend, Growth, Forecast & Industry Analysis (2022-2027) report, visit https://www.stratviewresearch.com/549/actuators-market.html