The transported modules weighed 18,535 tonnes

The transported modules weighed 18,535 tonnes

Sarens, a leader in heavy lifting, engineered transport and crane rental, has transported and installed 34 modules, with a total weight of 18,535 tonnes, in addition to te transportation and lifting of 108 heavy items, with a total weight of 12,283 tonnes, for the Jafurah Gas Plant Project.

Jafurah is one of the largest unconventional gas field development projects in the Middle East. Covering an area of 17,000 sq km, it contains around 200 trillion cu ft of gas and is rich in liquids, such as ethane, propane, butane and condensates.

This is a key part of the Jafurah plant, along with the NGL fractionation plant, the gas compression system, and a network of approximately 1,500 km of main transfer pipelines, flow lines and gathering pipelines, which aim to ensure the reliable supply of natural gas and condensates.

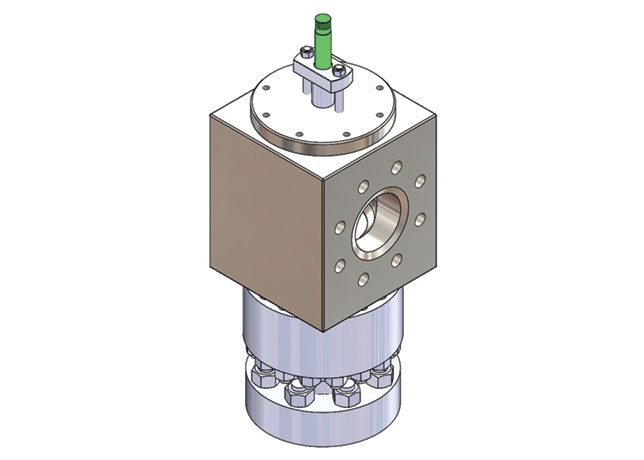

For the project, the Sarens engineering team selected three cranes with lifting capacities of 1,250, 600 and 150 tonnes, as well as a 120-axle SPMT (self propelled modular transport).

The main work was the transportation and lifting of a total of 34 modules, 30 piperacks and four process unit modules with electrical and mechanical equipment, with a total weight of 18,535 tonnes.

The heaviest module weighed 1,100 tonnes and the tallest was up to 42 m.

The 108 heavy items to be transported and lifted weighed a total of 12,283 tons, with the heaviest item weighing 493 tonnes.

To build the modules, a new Aramco external assembly yard was established near the gas field, where the units were manufactured and tested, using more than 11,000 tonnes of steel in the process.

Once completed, the modules were transported to the plant via SPMT.

The main challenge of the operation is the location of the plant, which is in a remote area of the desert, about 80 km from the nearest town, and exposed to adverse weather conditions.