The AIM suite offers advanced equipment testing and inspection

The AIM suite offers advanced equipment testing and inspection

Element Materials Technology has introduced a new set of asset integrity management (AIM) services, aimed at providing advanced testing and inspection for equipment firms involved in the upstream and downstream processing and refining of oil and natural gas.

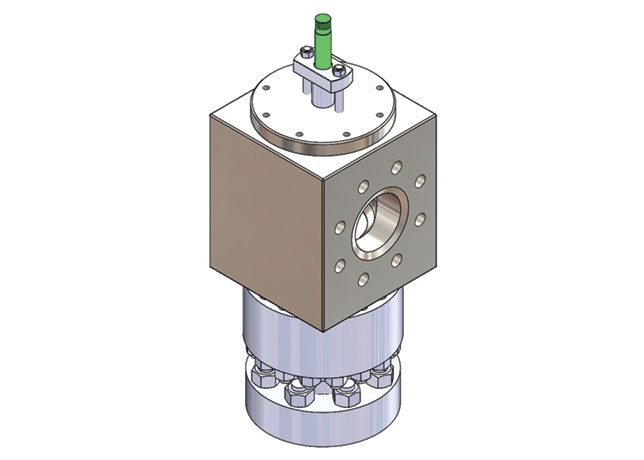

The suite includes condition monitoring with digital AI photography, onsite testing, structural analysis and corrosion monitoring.

Alongside the inspection services for ‘live’ equipment currently in service, Element now also offers failure analysis and remnant life assessment for parts and components that have failed prematurely.

Amongst the hub of services, Element has invested in cutting-edge, digital, AI-enabled visual examination technology from ABYSS Solutions.

Utilising advanced digital cameras and AI technology, Element can support with facility mapping, layout development for aging plants, as well as inspection reports on the severity of damaged, aging equipment.

ABYSS inspections include scanning for corrosion and cracking locations. Following this process, Element Digital Engineering performs the modelling, simulation and numerical analysis, as well as corrosion modelling.

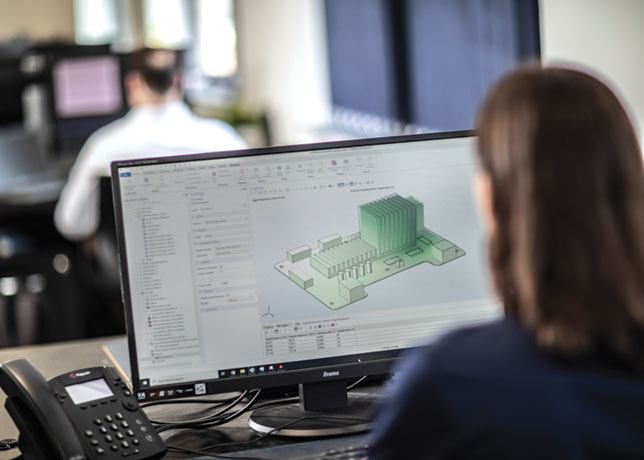

The leveraging of data, mathematics, and digital tools means Element is now able to support oil and gas operators with structural integrity assessments, and utilising CAD geometry and materials testing data to deliver high-quality technical insights.

Dr Basab Bhattacharya, Technical Lead for Energy, MEAP at Element Materials Technology said: "UAE, Qatar and Saudi Arabia are among the most important oil and gas refining hubs in the Middle East, and we are here to continue supporting businesses involved in the supply chain of this industry."

He added: "This is why we have developed a new suite of asset integrity management services, to support our wider testing and inspection services. It will enable us to ensure that plant and machinery stays in good condition, and any damage or potential failures can be spotted quickly before they become critically damaged.

Bhattacharya concluded: "We are also able to consult on why components may have failed prematurely. Our experts in our state-of-the-art laboratories and digital engineering teams can interpret the reasons for failures and offer advice on how to prevent the issue from occurring again."