3D printing reduces lead times for replacement components by 50 per cent

3D printing reduces lead times for replacement components by 50 per cent

Adnoc Gas has developed a digital library of critical components for the energy industry, which can be manufactured on demand using advanced 3D printing technology.

Over 3,500 items have been scanned and stored in a secure digital warehouse, generating an expected benefit of $50 million by 2028.

This technology, known as additive manufacturing, has reduced production lead times by 50 per cent, reducing operational downtime and allowing for greater inventory flexibility.

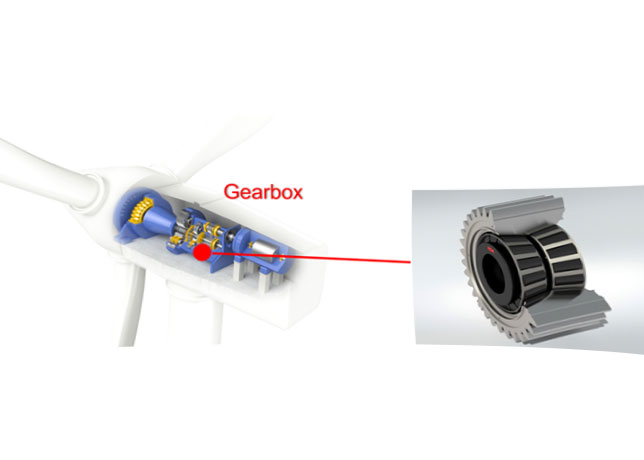

Adnoc Gas has used 3D printing technology provided by Immensa, a UAE-based market leader in additive printing and digital warehousing, to manufacture critical replacement components at its Das Island and Habshan gas processing sites.

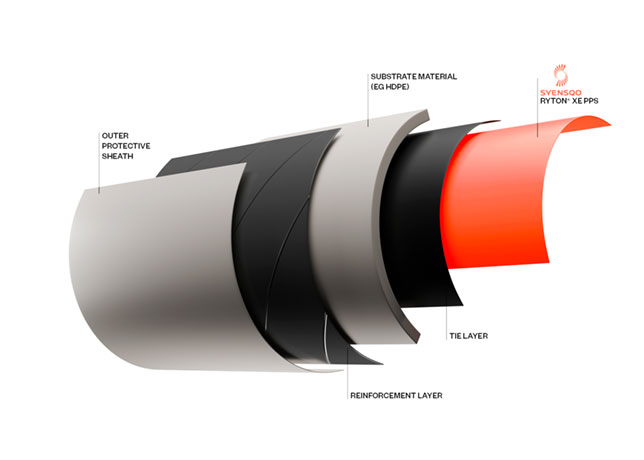

This approach has eliminated the need for overseas shipping, reduced CO2 emissions, and significantly reduced on-site inventories.

Dr Ahmed Alebri, Chief Executive Officer of Adnoc Gas, said: "3D printing provides an advanced digital solution for designing and producing components, optimising the company’s supply chain, enhancing performance, and reducing costs. It enables the creation of complex geometries and precise features impossible to achieve with traditional manufacturing methods. By leading the way in integrating additive manufacturing into our operations, we are driving forward operational excellence and delivering exceptional value to our stakeholders."

Adnoc Gas is exploring onsite 3D manufacturing to optimise operations and cut CO2 emissions and is partnering with Immensa to create and optimise 3D printing solutions specifically for the energy industry.

The company is harnessing the power of big data analytics, supercomputing, and artificial intelligence (AI) to optimise efficiency and sustainability across its operations and deliver greater shareholder value. Adnoc Gas expects AI to deliver benefits of $400 million a year for the next five years.