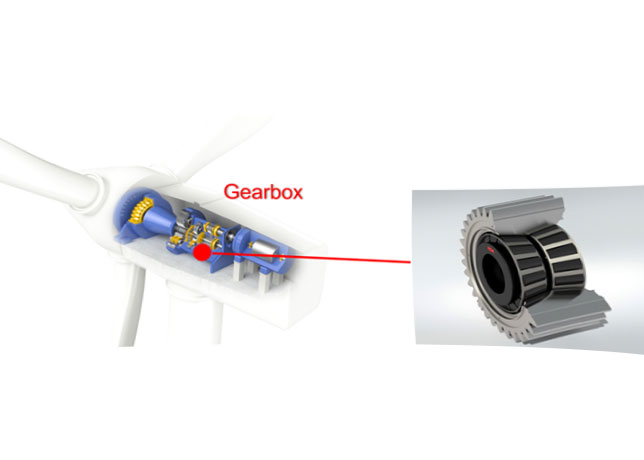

The gearbox of a wind turbine and the new NSK high-load tapered roller bearing

The gearbox of a wind turbine and the new NSK high-load tapered roller bearing

European wind turbine manufacturer NSK is set to use high-load-capacity tapered roller bearings in its 15 MW class offshore wind turbines.

The decision to use these bearings was based on several factors, including an increase in load capacity by 25 per cent over conventional products, longer bearing life, and lighter weight, which are ideal for reducing construction and maintenance costs.

The EU committed to 111 GW of offshore renewable energy by 2030 with 26 member states signing the European Wind Charter in 2023.

The high-load-capacity tapered roller bearing can overcome engineering challenges specific to wind turbines.

The optimised shape of the roller crown helps withstand the demanding operating conditions of wind turbine gearboxes.

NSK's numerical simulation expertise was used to derive the shape and equalise contact surface pressure between rollers and inner and outer rings, preventing excessive surface pressure at the roller ends, facilitating 25 per cent more load capacity and more than double the service life of the conventional product.

This results in a weight reduction of more than 30 per cent under the same usage conditions. NSK's expertise in production engineering led to the development of a new high-productivity processing technique to create the product's intricate crowning shape.