Championing EOR at Harweel

Championing EOR at Harweel

Petroleum Development Oman (PDO) has a number of pioneering enhanced oil recovery (EOR) projects in different phases of planning and operation. PDO recently released its report ‘EOR – Breaking New Ground in Oil Recovery’, an exhaustive bilingual dossier encapsulating the brief history of EOR and the company’s various related projects.

Talking about the importance of EOR, PDO’s managing director Raoul Restucci states: EOR is the future not only for PDO but for just about every company seeking to meet the world’s growing energy needs in the coming decades. The fact that Oman is regarded as a global centre of excellence for EOR is a source of pride to us at PDO, but perhaps more importantly it represents a tremendous opportunity to develop Omani skills and homegrown technologies that can be exported to the rest of the world, thus further diversifying the national economy."

PDO is one of the few oil companies in the world currently implementing EOR projects based on all three of the main available technologies – miscible-gas injection, steam injection and polymer flooding. The company is currently executing 16 EOR projects and trials, with a further six under concept review, putting PDO at the forefront of EOR delivery and placing Oman in the global spotlight.

At present, EOR accounts for around 11 per cent of PDO’s daily production, but the company expects this to rise to 33 per cent by 2023, an indication of how vital EOR is for the PDO. According to the report, PDO is ramping up its efforts to devise and test EOR technologies with the ultimate goal of providing all its fields with a suitable EOR roadmap, ensuring that oil and gas production remains an important contributor to Oman’s economy and PDO continues to play its part in meeting the world’s energy needs well into the future.

The report presents an valuable reference point of in-depth information on PDO’s four successful EOR field developments – miscible gas injection at Harweel, polymer injection at Marmul, and steam injection at Qarn Alam and Amal.

Miscible gas injection at Harweel: The Harweel miscible gas injection project came on stream in 2012 and by the end of 2013 production had risen to 30,000 barrels per day (bpd). PDO originally earmarked an additional 160 million barrels of oil that could be produced through miscible gas EOR at Harweel (2AB), but now the company is targeting a further 250 million barrels that will be delivered by a new, $1 billion plus project at Rabab Harweel.

This follow-up project, which is one- and-a-half times bigger than the existing Harweel (2AB) scheme, will see miscible gas injected into the seven Harweel oil reservoirs. It will also involve recycling sour gas in the neighbouring Rabab field to develop condensate, which is a low density liquid hydrocarbon associated with natural gas. Production from the Rabab-Harweel EOR project is expected to begin in 2019.

Polymer injection at Marmul: PDO launched the Marmul project in early 2010 and since then has been injecting some 100,000 barrels of polymer solution each day into the reservoir, with the aim of increasing daily oil production by 8,000 barrels and boosting the ultimate recovery factor from the reservoir to above 30 per cent. Thanks to the successful polymer flooding EOR project, by December 2013 Marmul had achieved the milestone of one million cubic metres (equivalent to 6.3 million barrels) of incremental oil production.

PDO now intends to expand the Marmul flooding operation in a move that will see the daily polymer injection increase to around 500,000 barrels, thus creating one of the largest projects of its kind in the world. PDO has also successfully launched a highly viscous polymer flood trial at its Nimr field, with plans to increase the scope of that project already in progress. And it is testing a different EOR technique called alkaline-surfactant- polymer, also at Marmul. This works in tandem with the established polymer technique, since the alkaline-surfactant mixture releases oil trapped in the reservoir, which is then swept from the reservoir using a polymer flood.

|

EOR in Qarn Alam |

Steam Injection at Qarn Alam: Thermal EOR takes several forms, many well established, but at Qarn Alam PDO has successfully created a world first in this area, one that is currently contributing around 25,000 bpd of production. It uses a procedure called thermally assisted gas-oil gravity drainage (TAGOGD), which has never previously been deployed on this scale in a reservoir featuring fractured carbonate rock. TAGOGD is ideal for highly fractured reservoir rock like that found in Qarn Alam, because the steam can be injected directly into the fractures, where it heats the surrounding rock and lowers the viscosity of the oil by a factor of up to 100 times.

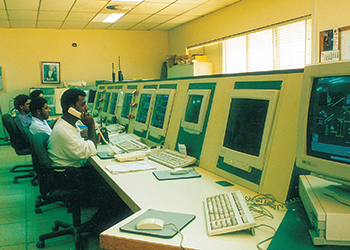

One of the keys to success at Qarn Alam has been the highly advanced reservoir surveillance, modelling and management systems PDO has put in place to help it make the right decisions in running the project. The company has drilled observation wells from which it could obtain data on reservoir pressures and temperatures, while further data are gathered from microseismic monitoring (where sensors pick up and record minute rock movements) and regular fluid sampling in its lab. All these data can be analysed and modelled in real time, enabling us to keep on top of progress at Qarn Alam 24/7.

Having recovered only around 4 per cent of the estimated reserves in Qarn Alam since PDO discovered the field back in the mid-1970s, the company expects the thermal EOR project to boost that figure beyond 30 per cent in the coming years, enabling Qarn Alam to finally fulfil its vast potential. PDO is also hoping to replicate the success of the ground-breaking Qarn Alam project in the rest of the fractured carbonate reservoirs in the North of Oman, including with a new TAGOGD trial in its Fahud field, which contains oil that is less viscous but where the reservoir rock is equally heavily fractured.

Amal Solar Steam: In its twin fields in Amal – Amal East and Amal West – PDO is injecting steam into the reservoir rock to encourage the viscous oil to flow more freely. As at Qarn Alam, steam is generated in Amal through recycled heat from the power generation process as well as conventional steam boilers that utilise fuel gas. But gas is a precious commodity in Oman, so as part of its ‘Energy Efficiency Strategy’ and its drive to reduce the carbon footprint, PDO sought alternatives to natural gas for generating the steam required for its thermal EOR projects – starting with solar steam.

The Amal West solar steam plant is based on an established technology called concentrated solar power, or CSP. Here mirrors are used to direct the sun’s rays onto steel collecting tubes, which heat up to around 300 degrees centigrade, acting like a kettle element that turns water pumped through it into steam. A faultless first year of operation saw the plant save almost a million cubic metres of gas (compared with conventional, fossil fuel steam generation), while at the same time reducing the carbon footprint by some 1,800 tonnes of carbon dioxide.

PDO believes there is tremendous further potential for harnessing solar energy within Oman’s oil and gas sector. This in turn offers a unique opportunity for the Sultanate to position itself as a regional hub for renewable technologies, helping to further diversify the economy and creating skilled employment prospects for Omanis.