Air audits can help plants save 10-20 per cent in operating costs

Air audits can help plants save 10-20 per cent in operating costs

Air audit is a very critical activity in the design of optimum sized compressed air system and can bring tangible and intangible benefits for a customer, Sanjeev Sharma, Regional General Manager at Atlas Copco Services Middle East, tells OGN

Did you know that the capital investment on an air compressor system accounts only for around 8 per cent to 10 per cent of the life cycle cost (LCC)? What else contributes to the LCC? The answer is energy.

'Energy on operating a compressor can contribute between 70-80 per cent of the LCC of a compressor depending on the energy tariff in the country/region. In some Emirates of the UAE, energy costs can contribute up to 85 per cent of the compressor LCC,' says Sanjeev Sharma, Regional General Manager at Atlas Copco Services Middle East.

Globally, 75 per cent of manufacturing facilities have the potential to reduce the cost of energy by avoiding wastage and optimisation of the compressed air plant.

The first step is to do a comprehensive compressed air audit or air scan.

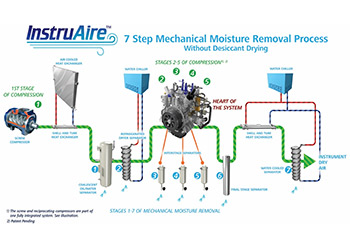

Air audit is a comprehensive audit of your entire compressed air installation, including energy input, air flow demand, system pressure, air quality, pressure drops, and more, over a significant period.

|

The result of an air audit will show:

1) A complete compressed air installation audit.

2) Find out existing wastage or problem areas.

3) Define energy efficiency, air quality, leakage analysis running conditions.

4) Define and simulate potential solutions, quality saving and propose solutions.

This is the start of any optimisation process. After the air audit, the major potential areas for optimisation will normally include:

1. Usage of right compression technology: Depending on the quantity of compressed air demand, different compressed air generation technologies can be compared to analyse the potential savings from them.

Each technology has an ideal working flow range and the specific energy consumption can be lower or higher by 5-20 per cent between technologies depending on flow and working pressure.

Case: After air audit, a manufacturing plant has 2,531 cfm air demand and is using oil injected screw compressor for its compressed air generation.

For the high air demand of 2,531 cfm, if the compression technology is switched from oil injected screw to centrifugal compressor for compressed air generation, the potential cost of energy saving is $44,995 (Table 1).

During an air audit, a current logger and power logger installed in the compressor will give all data related to power consumption.

2. Understanding the utilisation factor and demand pattern: In general, a majority of the industrial applications have a fluctuating air demand, and compressors are sized for meeting the maximum compressed air demand.

A typical weekly demand pattern of industrial plant can be as this: During an air audit, a flow measurement logger installed will give a profile or demand pattern giving a clearer picture of the minimum air demand, average air demand and peak air demand. Once the demand pattern is available the potential saving can be simulated with usage of variable speed driven compressors.

The potential saving on cost of energy can be anywhere between 20-40 per cent depending on the fluctuations. Variable speed driven compressor follow the demand pattern closely varying the motor speed of the compressor and eliminating unload running losses, which results in substantial savings.

3. Detection of air leaks and pressure drop in compressed air piping system: A well-planned air audit typically puts high focus on the air distribution network besides the generation side. A poorly designed air distribution system takes away all advantage of a well-designed compressor plant.

Most of the compressed air plants are designed considering a 10 per cent margin kept for air leakages. This is done to ensure that compressed air plant is not undersized as every air compressor system has some degree of leaks which build overtime.

Leaks often become a huge burden on the compressor system operating costs and one of the key activities during an air audit is to do the air leak detection and ensure the leaks are eliminated.

This can potentially bring savings on operating costs anywhere between 10-20 per cent depending on the age of the plant and materials used in the compressed air distribution system.

Also, another major aspect of an air audit is to measure pressure drop across the distribution system.

Typically, a well-designed air distribution system operates with minimal pressure drop. However, more often over the years, the distribution system remains the same while the plant air demand grows with growing production and expansions.

Eliminating pressure drops by adding additional lines can save the user substantially on energy. One bar of pressure drop can cost up to 7 per cent extra energy and an audit will highlight this aspect which often gets unnoticed during normal plant operations.

4. Air quality: Having the right compressed air quality is critical for any manufacturing plant. The quality of air depends on the process and applications of an industry type. Compressed air quality check is a major aspect of a well-planned air audit.

Depending on the process requirements, the air audit team will carry out measurements on dew point and performance of the filtration system. The team will then recommend adequate actions that can not only help achieve the expected air quality but also help in reducing the impact of poor air quality that makes on the process as well as energy consumption of the plant by reducing pressure drops across the dryer and filters.

High quality compressed air reduces the need for maintenance, increases operating reliability of the pneumatic system, control system and instrumentation while limiting wear of the air-powered machines.

CONCLUSION

Air audit is a very critical activity in design of optimum sized compressed air system and can bring tangible and intangible benefits for a customer. Audit can bring potential energy saving from 20-50 per cent in a typical industrial installation. An air audit is recommended at least once every year.