Businesses are investing heavily in sustainable hydrogen production

Businesses are investing heavily in sustainable hydrogen production

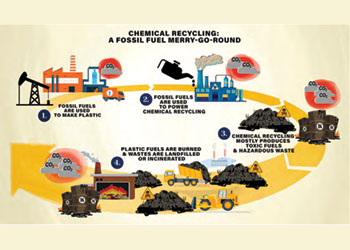

The topic of carbon emissions and footprints has been under discussion for a long time now. And these emission are in no way decreasing especially as demand for energy grows.

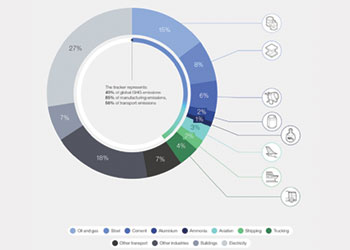

Amongst all sectors, transportation has seen the greatest demand for oil, and this has resulted in an increase of 2.5 per cent, or 268 metric tons (Mt), to 11.2 gigatons (Gt) in CO2 emissions in 2022.

In terms of natural gas, emissions decreased by 1.6 per cent, particularly in the Asia-Pacific and Europe.

The oil and gas industry can reduce CO2 emissions significantly by implementing strategies such as carbon capture and storage, investing in low-carbon technologies, and integrating renewable energy.

THE SUSTAINABILITY WAVE IN THE INDUSTRY

The oil and gas sector has been gradually moving towards cleaner and greener practices, with numerous developments underway making it easy for industry processes to ride the sustainability wave.

The primary contribution comes from the production technology side, where energy efficiency is prioritised to achieve maximum output even at low energy levels.

Utilising electricity rather than coal is now feasible thanks to technological advancements, and production becomes environment-friendly if the electricity originates from renewable resources like solar or wind.

In fact, a lot of businesses are expanding their product lines to include bio-based derivatives.

Mitsui Chemicals, for instance, holds certification for manufacturing bio-based derivatives.

By acquiring the bio-based BDO from Qore, BASF can cut its carbon footprint by approximately 86 per cent in comparison to BDO derived from fossil fuels.

CONCERNS ABOUT HYDROGEN

There are numerous methods to create hydrogen, and businesses and sectors are eager to incorporate them into their manufacturing processes.

And while each of these approaches has benefits and drawbacks, one of the most important issues to address and improve upon is the significant release of CO2 emissions.

Steam reforming is one technique that is widely used because it can affordably produce hydrogen on an industrial scale.

Typically, the production process yields 8–10 kg of CO2 for every kg of hydrogen. This method allows to produce 90 per cent of the hydrogen produced by all methods combined.

If renewable energy sources are used instead of fossil fuels, some techniques can be classified as completely clean and green energy production methods, like electrolysis.

The lack of infrastructure and the high cost of production remain two of the primary reasons why the adoption of green hydrogen is not happening at a fast pace.

Thus, it wouldn’t be wrong to say that industries are extensively contributing to the creation of more CO2 because of hydrogen production.

The solution to this problem can be carbon capture technologies, which can help collect the released CO2. One such technology is CCUS. The production of hydrogen moves one step closer to being green when such methods incorporate CO2-capturing technologies. However, the deployment of CCUS comes with its own cost-related issues.

IMPACT OF CCUS ON COST OF HYDROGEN PRODUCTION

There are unique obstacles, such as financial constraints, associated with the deployment of CCUS during hydrogen production.

Over time, managing the CO2 released during hydrogen production has become increasingly significant.

The cost per kilogram of natural gas produced in recent years has ranged from $0.7 to $1.6. The cost of the entire hydrogen production process may, however, go up with the deployment of CCUS.

The cost of green hydrogen would be around $4 to $5 per kg over the next 20 years, while the cost of gray hydrogen can be from $2 to $2.5 per kg.

Further, blue hydrogen can be 10-15 per cent higher than gray hydrogen due to the cost contribution of CCUS.

Moreover, the price difference between green and blue would vary depending on the regions, renewable energy, and natural gas costs, among other factors.

However, the subsidies for green would be higher so that it could compete against blue hydrogen.

This increase in price may hinder the adoption of targeted initiatives to develop processes that capture CO2 emissions.

Nonetheless, there are numerous tax credit programmes and government incentives that can assist businesses in leveling the cost envelope.

Green hydrogen production may also increase due to the declining cost of renewable energy.

Countries like India, where renewable energy is available at a low cost, are surely going to boost their green hydrogen production capacities in the future.

Many significant players are collaborating to obtain better technology that will enable them to reduce their carbon footprints along the value chain.

Businesses are investing heavily in sustainable hydrogen production. For example, industrial key players such as BASF, Linde, and SABIC are developing a one-of-a-kind electric steam cracker. Compared to existing technologies, this type of cracker has the potential to reduce carbon emissions by approximately 90 per cent.

FUTURE OUTLOOK

Due to its minimal or nonexistent impact on reducing carbon emissions, blue hydrogen may encounter challenges in the future.

In order to lessen their reliance on outside suppliers, businesses are also concentrating more on internal renewable energy production. Refineries are also looking for new derivatives in order to allocate feedstocks to compensate for the reduced demand for petrol/diesel due to the shift from internal combustion engine (ICE) to EV.

The future of cleaner and green practices in the oil and gas industry is looking promising because of incentives, increased investments, and extensive shows of interest.

* Vikash Kumar is Program Lead, Polymers and Materials, at ChemBizR, a s pecialised chemical business research and consulting company, and Jasleen Kaur, Marketing and Communication Specialist.