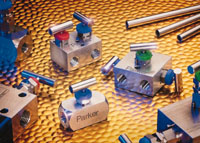

Parker Hannifin has launched a new range of miniature stainless steel needle valves and manifolds for fluid instrumentation applications which provide exceptional size savings without sacrificing performance.

The range operates at up to 414 bar (6000PSI), and offers bubbletight seating and sealing with lifecycles of more than 6,000 operations, yet typically reduce weight and space requirements by 50 per cent compared with conventional products.

The High Performance Miniature range includes two- and three-way manifolds for pressure and flow measurement applications, and a needle valve range which can be specified in globe or angled flow patterns. The needle valves are available with a user-specified choice of female or male interfaces, and may additionally be provided with integral single- or double-female CPI or ALOK compression tube connections.

These latter options halve potential leak paths and assembly labour requirements compared with conventional pipe threaded connections.

Valves are fitted with Viton 'O' ring seals, supporting an operating temperature range up to 204¡C. This sealing system is designed for high integrity, and features an anti-extrusion backup ring, plus an anti-blowout design with back seating which minimises atmospheric leakage in the event of a stem seal failure.

The high performance of the new range makes the products suitable for gas or liquid applications. The space savings are likely to be of particular interest to panel builders, and any other application where space or weight is at a premium, such as on offshore platforms and in portable equipment.

As an example of the savings made possible by Parker's new range, the body of the three-way manifold measures 51 x 51 x 27mm. The whole unit, complete with its miniature valve assemblies, weighs just 550g.

Parker Hannifin says that it is a worldwide leader in the production of motion, control and critical flow components and systems for hundreds of instrumentation, industrial and aerospace markets.