KNPC ... modernising the Mina Al Ahmadi refinery

KNPC ... modernising the Mina Al Ahmadi refinery

Name of client : KNPC – Kuwait National Petroleum Company

Revised budget : $900 million

Facility type : Gas production

Sector : Gas

Status : Engineering & Procurement

Location : Mina Al Ahmadi

Feed : AMEC

Background

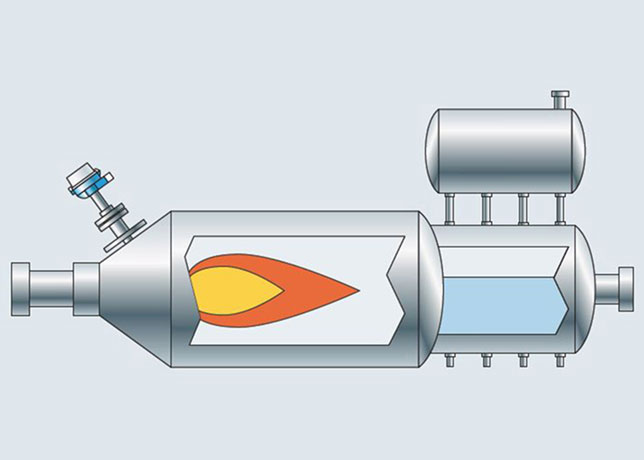

Mina Al-Ahmadi Refinery Modernisation Project (RMP) was basically intended to provide the local and world markets with low sulphur-content petroleum products, and to reduce dependence on gas as fuel.

Project status

May 2015:Tecnicas Reunidas wins contract to build the fifth gas new fractionation train at Kuwait’s Mina Al-Ahmadi refinery.

Project scope

The scope of the scheme involves:

•Feed gas compressor;

• Feed gas dehydration;

• LPG dehydration;

• NGL recovery;

• Fractionation & product treating unit;

• Substation;

• Flare system;

• Nitrogen generation & distribution system; and

• Air compression system.

The fifth gas train is designed to process associated gas and condensate from KOC gathering centres in southeast Kuwait and north Kuwait oil fields. It will also be supplied with refinery gases from the acid gas removal plants at the two other refineries owned and operated by the KNPC Shuaibah refinery and Mina Abdullah refinery.

Project schedule

Feasibility Study Q2-2011

EPC ITB Q3-2014

Engineering & Procurement Q2-2015

Construction Q4-2015

Completion Q4-2017