MH Hydraulics FZC, a leading hydraulic solutions provider in the Middle East, provides an insight into headspace management in hydraulic and lubrication systems.

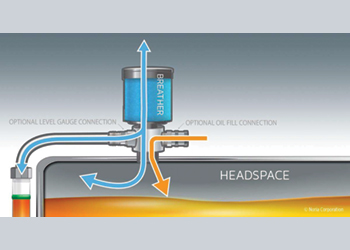

Headspace is the clearance between the inside ceiling of an oil tank or reservoir, and the top of the lubricant or oil within the container or it is simply the air above the oil in tanks, reservoirs, and lubrication compartments.

It is important to manage the headspace because equipment breathes. As we use our equipment, there will be oil level fluctuations in the reservoir. When the oil level drops, we need to draw in air from the atmosphere; and when the level rises, we need to expel air from the inside of the tank to the outside.

During this breathing, there are possibilities of moisture and dirt particles entering the tank or reservoir and getting in contact with the lubricant or oil and causing oil contamination.

There are three ways to manage oil contamination:

• Monitoring – visual inspections and oil analysis;

• Removing – by means of filtration; and

• Excluding – by using efficient breathers.

There are many ways to carry out visual inspections to monitor the condition of oil or lubricant such as by using sight glasses and by installing permanent sampling ports on the tank for collecting oil samples from time to time for external laboratory analysis.

Having a dedicated offline filtration system can help to remove the contaminants from the lubricant or oil.

The best practice, however, is to prevent oil contamination. Studies show it costs about 10 times as much to remove contamination as it does to exclude it.

Having an efficient breather is vital for a clean and dry headspace. Breathers absorb moisture in the headspace and keeps the air inside the reservoir dry. The breather also limits dirt particles entering the reservoir.

Most of the OEM breathers are not effective, they only prevent solid particles from entering the tank. A quality desiccant breather can ensure a clean and dry headspace. It combines a drying media with a combination of filters to prohibit water and microscopic particulates from entering the system, and to remove water from the reservoir to prevent condensation.

Desiccant breathers are not expensive for example, Des-Case DC-2 Model costs approximately $65 while Des-Case KL93 Model costs $150. Having a desiccant breather is an economical way of managing headspace and thereby, limiting oil contamination.

So how does one select the right size of desiccant breather? The technical article in our online edition (https://ognnews.com/) provides the details.