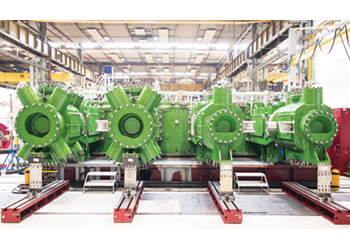

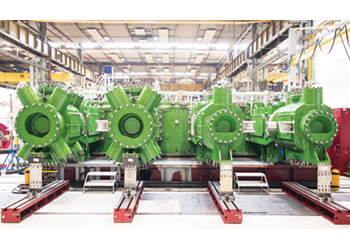

Reciprocating compressor built for KNPC

Reciprocating compressor built for KNPC

While it is crucial for oil and gas to drive sustainability throughout its processes, the role of compressors in the transition to a more sustainable future will be central, Massimo Bizzi, COO, Howden group, tells OGN

As governments and industries across the world look for ways to become more sustainable, ‘energy transition’ is the phrase that is becoming increasingly popular.

Strictly speaking, the term would refer to the decreasing use of fossil fuels in our economy’s energy mix. However, in reality, the term has been extended to mean much more, being synonymous with decarbonisation and moves toward a net-zero or low-carbon society.

This transition in the energy market is necessary to preserve the needs of future generations and will take years of continuous change to both processes and business cultures. It will be driven by innovation and evolution towards a better state of lower consumption, cleaner energy production and reduced CO2 emissions.

Our vision at Howden is to enable our customers’ vital processes, which advance a more sustainable world. Our technical expertise, application knowledge, global reach and specific products like our market leading compressors, give Howden specific insight and practical experience in supporting the energy transition for our customers.

The energy transition often comprises three main themes: the shift in the energy mix, the adoption of carbon capture technology, and an increased focus on efficiency improvements. Compressors have a vital role to play in each of these themes.

ENERGY MIX

|

Bizzi ... offering efficient compressors |

The first theme is the shift in the energy mix. For a successful energy transition there needs to be an increasing percentage of renewables, such as solar and wind, and the adoption of other zero or low carbon energy resources in use, such as nuclear and biofuels.

This theme represents the very core of the energy transition and it is the main challenge for the traditional energy industry.

One exciting industry that looks set to become key is the hydrogen market. With over 100 years of experience in the compression of hydrogen, Howden’s industry leading compression solutions will be instrumental in the energy transition by, amongst other things, advancing the environmental hydrogen eco-system and modernising the oil and gas industry.

With solar becoming more competitive than any other energy resources, as confirmed by the International Energy Agency’s (IEA) in their World Energy Outlook 2020, hydrogen has taken a key role in the energy industry.

Hydrogen offers a solution to the intermittent and unreliable nature of solar and wind, which has been, together with cost, a significant hurdle in the adoption of renewables, having the capability and capacity to provide energy storage and thus balance demand with energy produced by renewable sources.

Hydrogen is very versatile and offers some additional degrees of freedom when compared to electric batteries. It can be used for power generation in fuel cells and in mobility in cars and trucks.

Hydrogen can also be blended with natural gas in pipelines (provided some specification requirements in the pipeline are met), and used in traditional combustion-based processes, creating an immediate impact of carbon reduction.

It can also be used as a chemical reactant in many industrial processes. It can be converted into ammonia, which then can be used as a chemical or as a fuel.

Hydrogen can also be used as a reduction agent in ‘fossil-free’ steel production, or as a reactant for e-methanol, which can then be used as a blend in traditional fuels.

The expansion and importance of the hydrogen industry is clear in the additional funding and attention it has received from economies and governments around the globe.

Howden’s strong offering in hydrogen is based on decades of focused experience in the oil and gas industry.

With thousands of active references on hydrogen compression alone, our experience in the field is certainly very significant. Our reciprocating compressors – both diaphragm compressors and piston compressors – have been key in driving this industry forward.

Our ‘Burton Corblin’ Diaphragm Compressors, invented by Henri Corblin in 1916, provide zero contamination, leak-tight compression of any gas and can reach high pressures of up to 3,000 bar.

Our Thomassen piston compressors provide one of the most trusted solutions in the industry, especially when high pressure and significant flow rates are required.

Projects large and small will be necessary for a worldwide shift to more renewables in the energy mix, and Howden has proven its ability to deliver on all scales including the largest hydrogen compression system in the world.

Kuwait National Petroleum Company (KNPC) upgraded two of its existing refineries, and in 2015 and 2016, Howden delivered Thomassen compressors to the engineering firm Fluor to build the largest API618 reciprocating compressor system ever constructed for hydrogen service.

The eight-cylinder Thomassen C-85 reciprocating compressor was delivered within a challenging one-year deadline.

The compressor is one in a series of six, delivered over a six-month period, which processes more than 1,000,000 Nm3/h of high pressure hydrogen.

This project was a key milestone, as very similar compressor technology has been used lately by Howden in several renewable hydrogen compression applications, where hydrogen is produced by electrolysis.

This highlights the importance of the link between the traditional energy industry and the increasingly popular renewable hydrogen, where reliable and well proven solutions can be adopted to improve safety and accelerate the evolution of process performance in this fast growing industry.

Another application of great interest is the use of Howden compressors in the world’s largest hydrogen refuelling station (HRS): the Beijing Daxing HRS in China.

The Daxing HRS has the capacity to produce 4.8 tonnes per day of hydrogen and refuel up to 600 hydrogen fuel cell vehicles, including large vehicles such as trucks and buses.0

The Daxing HRS is part of the 200,000 sq-m Beijing International Hydrogen Energy Demonstration Zone.

In this project, Howden diaphragm compressors were selected, showing again the credibility of our brand and how technologies that have been used for decades in the industry now provide important building blocks to the new hydrogen economy.

DECARBONISATION

The second general theme of the energy transition, central to the oil and gas industry, is carbon capture, storage and utilisation (CCUS).

In my view, there is broad agreement across the energy community that CCUS remains necessary to hit the CO2 reduction targets set out by the Paris agreement and COP26.

However, it is also true that some may have a less generous view of CCUS as it could be perceived to mitigate any commitment to phase out fossil fuels.

There is widespread recognition that the utilisation of CCUS will be a challenge when considering the very high amounts of CO2 that will need to be captured, and the most credible technical solution still remains underground storage.

Unlike hydrogen combined with renewables, the real economic case for CCUS remains a challenge and CCSU will be likely adopted purely as a way to avoid CO2 emissions.

Without a profit-based business case creating a driving force to increase adoption, the technology would then rely heavily upon governmental policies.

At the same time, when considering the challenging net carbon zero targets of all major economies, it is difficult to imagine how these targets can be achieved without a contribution from this technology.

The technologies are in place and they have a well demonstrated track record of technical feasibility.

Our involvement in CCUS has seen us provide gas handling solutions for all the different technologies currently available in the market.

Howden has participated for example in the development of the first rotating adsorption machine, and has also supported traditional solvent based technologies with fans and compressors.

Consistent with our vision, we continue to work on the market to enable the different CCUS technologies with our gas handling solutions, and we are contributing to create an ecosystem of technology partners that can tackle the challenge of carbon capture.

ENERGY EFFICIENCY

The third and final theme of the energy transition is the need for efficiency improvements and waste reduction.

The extension of Howden’s product range beyond compressors and into areas including steam turbines, mechanical vapour compression, low grade waste heat and heat pumps, demonstrates our over-arching focus on the energy transition and enabling our customers to be more sustainable.

Of course, compressors still play a central role in this theme too. For example, Mechanical Vapour Recompression (MVR) increases the pressure of vapours and recovers the energy of evaporation, thus reducing primary energy consumption and leading to a net energy saving.

We have undertaken more than 2,500 MVR installations in over 70 countries with a range of 5 to 6,600 kW per compressor. This leads to a total of 1.3 million kW installed.

It is now crucial that the oil and gas industry focuses on the energy transition and driving sustainability throughout all of its processes.

It is the responsibility of everyone to make the changes a priority and it will require collaboration of experts and technologies.

As outlined, there are multiple themes and applications to consider but at Howden, we are proud of our technical innovations and of the central role compressors will play in the transition to a more sustainable future.