Irwin ... finding the right solution

Irwin ... finding the right solution

Market-leading asset lifecycle information management software by Bentley can help organisations unlock the value in their digital information from the day it is deployed, Richard Irwin of Bentley Systems, tells OGN

Asset-intensive industries, such as oil, gas, and process industries, mining, electric, gas, and water utilities, and rail and transit transportation, rely on accurate, comprehensive, and up-to-date information for effective operations.

However, through maintenance, procurement, modifications, and upgrades, asset information is always changing, and all these functions use the same information.

Therefore, it is imperative that asset information is consistent across all consumers to ensure safe, reliable, and efficient operations, says Richard Irwin, Senior Product Marketer for Digital Twin and Industry Marketing, Bentley Systems.

But the information is often held in disparate and unconnected silos with limited management of change across the digital ecosystem, resulting in personnel spending a lot of time trying to find the information they need and verifying its validity and accuracy.

This can result in making wrong decisions and increasing costs due to duplication or the wrong work being carried out, which ultimately puts the safety of the workers and the reputation of the organisation at serious risk.

What is required is a digital solution that connects these disparate sources together, validates the information, brings visibility to all changes across the asset lifecycle, and ensures reliability at the point of use.

Market-leading asset lifecycle information management software, such as Bentley’s AssetWise® ALIM, can help organisations unlock the value in their digital information from the day it is deployed.

Whether a company is in the planning stage of a new project, or operating an existing asset, it needs a flexible system that is easy to implement and ready when it takes the first step on an asset management or digital twin journey to save costs, improve safety, and reduce risk.

RELIABLE INFORMATION IS THE FOUNDATION OF A DIGITAL TWIN

A digital twin is a virtual representation of real-world entities and processes, synchronised at a specified frequency and fidelity.

Digital twin systems transform business by accelerating holistic understanding, supporting optimal decision-making, and enabling effective action.

An ALIM system can be the foundation of your digital twin solution, where the information and data it manages ensures that the digital twin is always consistent and up to date by synchronising with ALIM.

This allows control of the lifecycle information quickly and easily by tailoring the solution with the addition of advanced tag management, document control, or developing robust change management workflows.

|

The reality model of a facility provides a clear presentation of the actual site |

As such, organisations can work toward an immersive asset environment in which an object within a model can be clicked on to reveal its information, documentation, and change history.

Ideally, an ALIM system should operate in an open, interoperable, and connected environment, offering a set of cloud-provisioned services that provides support to digital workflows, context, and concepts, enabling access to accurate, reliable, and consistent information.

A set of standard connectors to multiple third-party systems, such as SAP and Maximo, ensures all users are accessing a common, validated, and up-to-date source.

As you build up a digital picture of your asset, an asset information management solution validates the information against your specifications and across sources, building trust.

This information is made available to any stakeholders who need it, wherever they are located.

Changes are managed and then made available, guaranteeing that everyone is working with the same, up-to-date information.

SUPPORT YOUR DIGITAL TWIN

Used as the starting point of the digital solution, ALIM is integral for keeping digital twin evergreen through formal change management and workflow automation.

This is achieved within AssetWise ALIM via an iTwin viewer that enables access to the asset’s operational information in the context of reality models, 3D models, and 2D drawings.

ALIM users can search for assets based on specific criteria and then visualise them within the iTwin platform for further analysis.

The iTwin viewer simplifies daily operation and maintenance activities by providing quick access to relevant and up-to-date asset information such as operational objects, related documentation, affected change requests, and projects, providing complete visibility of the asset’s status including any planned changes.

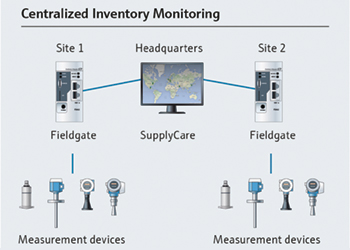

|

The ALIM system allows to view relevant and up-to-date |

This visualisation aspect provides effective tools to navigate within the model, find information faster, highlight critical asset data, and share information easily.

ALIM is the ideal entry point for your digital twin strategy and can be easily scaled up to advanced use cases by using PlantSight.

ALIM’s flexibility and openness means you can work with the information you have within third-party software – by supporting interoperability, the data doesn’t have to come from Bentley applications.

ALIM also provides integration with other mission critical systems including SAP and Maximo.

Sixty-nine percent of operations executives in the 2020 Verdantix survey mentioned open architecture for integration as either a 'very important' or an 'important' criterion when evaluating software applications for asset management.

AssetWise, including ALIM, works within an organisation’s your existing information ecosystem to drive actional information from the data you have.

REMOTE FAMILIARISATION & CONTROL OF WORK

Safety requirements, workforce flexibility, remote sites, and infrequent maintenance are driving the need for virtual, simultaneous familiarisation and control of work.

A digital visualisation layer, such as that provided by Bentley within its ALIM application, allows a facility to enable dedicated teams, workers, and contractors to prepare work safely and efficiently, while reducing the need for on-site visits.

This familiarisation is also critical for supporting daily operations and ensuring that processes are executed safely and on time.

The visualisation provides the context for managing work on site by displaying the operational status of the assets and ensuring a holistic view of the operational information that is needed to perform tasks.

This is valuable when planning or working on a specific area of a facility as it provides a quick visual assessment on a piece of equipment, showing what changes may be pending as well as the equipment’s detailed information.

USER STORIES

AssetWise ALIM has been successfully implemented over many years across a wide range of industries, delivering tremendous benefits and ROI.

Here are two examples highlighting how ALIM delivered trusted information to engineering, operations, and maintenance teams.

One of Australia’s leading natural gas producers, based in Queensland, has a master tag registry for its assets that includes over 20 million data points.

To handle a doubling of data from documents and model files, as well as migration of documents from systems based on energy performance certificates, the company uses AssetWise ALIM software, hosted on Microsoft Azure.

This has reduced tag capture time by 90 per cent, as well as lost time from maintenance crews arriving on site without correct parts and tools.

The Ameren Callaway Energy Center in Missouri, US, is a nuclear power plant that started operating in 1984.

The efficiencies introduced by using AssetWise ALIM as a single modern platform for Ameren’s information management system ensured timely and effective modification and maintenance during scheduled plant outages, significantly reducing costs.

Using ALIM’s relationship capabilities to automate manual processes and streamline information improved its access and accuracy, reducing the time required for plant staff to find and verify documents and resulting in less rework.