Firms that effectively leverage AI have a distinct advantage

Firms that effectively leverage AI have a distinct advantage

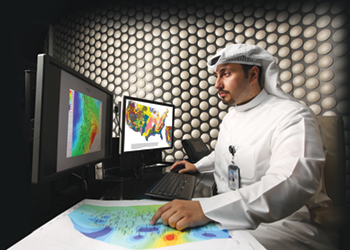

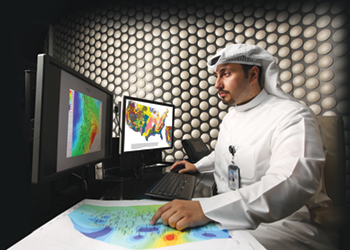

Data captured from the field is huge and if obtained and utilised, it will help companies improve operations in the downstream, upstream or even in the back-end, says Wassim Sleiman, Country GM-Kuwait, GBM

Kuwait's oil and gas industry is witnessing rapid adoption of digital technologies, something crucial to achieving operational efficiency while increasing production output.

At the centre of these technologies is data, which is produced in huge amounts. It is, therefore, important that a mechanism be put in place to store this data and make it available whenever needed.

"The data captured from the field is huge. If we can get this data and build what we call the knowledge base database system for the oil industry, it will help companies improve their operations whether in the downstream, upstream or even in the back-end," Wassim Sleiman, Country GM-Kuwait, GBM, said in a webinar held by Forbes Middle East.

As the fifth largest oil producer in the world, Kuwait’s economy is primarily driven by the oil and gas industry; and data, for the industry, is the key to its transformation and its future.

Systems such as artificial intelligence (AI) or machine learning (ML) used to extract information are primarily built on data.

IBM says it is working to build what it calls Kuwait Oil Knowledge Database System to harness data and the information that resides within it.

With technologies evolving rapidly, oil and gas companies need to be flexible to take advantage of innovations.

Shoaib Niyazi, Energy, Utilities, Materials, Industrials Industry Leader at IBM, says companies that effectively leverage AI today have a distinct advantage over those that lack an accurate understanding of their reservoirs, operating processes and producing assets.

He says broader industry trends such as commodity cycles, capital planning challenges and increasing operational risk make it more important than ever to make smarter and more efficient decision.

He says AI and automating have benefits across the entire value chain, including exploration, drilling, production and even sustainability.

In exploration, operators can make use of AI and ML to better understand reservoirs, mimimise geoscience risk, and to make better exploration and production decisions.

Niyazi cites a case study where a client managed to reduce time spent by the geoscience team reading and searching through data source by 75 per cent, in addition to reducing analysis time from six weeks to just three days.

In drilling, AI has proven to be very effective at improving well design, drilling execution and well completion, with the ability to be customised to the area’s geology.

Producers can maximise ROI on every well by optimising well placement and well spacing, well design (to optimise recovery and total cost) and predict subsurface risk.

When it comes to the success of production, accurate well production forecasts are critical.

It is here that ML machine learning can help optimise flow rates, pressure and other variables to maximise lifetime well productions.

Additionally, anomaly detection capabilities allow operators to anticipate well issues well before they cut off production.

In process and refining, AI can come in handy for predictive maintenance and maintenance optimisation.

Niyazi says operators can model and quantify the risk of failure for key critical equipment part during maintenance shutdowns to allow them to make more informed decisions about scope and reduce total shutdown cost, and to improve asset reliability.

For a customers, he says, maintenance optimisation save them approximately $400 million per year in maintenance costs.

Also in sustainability, AI and analytics solutions are helping oil and gas companies with accurate calculation of Scope 1, 2, 3 emissions and to record and track progress on their decarbonisation goals.

Niyazi, however, cautions against the significant exposure of oil and gas companies to cyberattacks due to digitalisation, and says an effective AI-based security solution, which holistically addresses an end-to-end security exposure, is critical for the long-term success and resilience of the organisation.

GBM EMPOWERING DIGITALISATION OF KUWAITI O&G

GBM has been working for over 20 years with oil and gas stakeholders in Kuwait to help them on their digital transformation a journeys. These include Kuwait Oil Company (KOC), Kuwait Petroleum Corporation (KPC), Kuwait Gulf Oil Company (KGOC) and others.

The company focuses on three key areas in digital transformation:

• Customer experience: By changing the interaction of the customers (of the oil companies), GBM gives them a closer look from a technological perspective. Through a common interface, the oil industry can communicate with partners and distributors.

• Transforming the business model: This involves operations, whether it is in the backend, upstream or the downstream. For example, through IBM’s Maximo suite, oil firms can do predictive maintenance. This allows them to sustain their operations for a longer time and avoid any downtime, which can be costly.

"We have adopted a lot of IoT technology and intelligence into this business model to enhance the operations of companies," says Sleiman.

• Operational processes: GBM is working with KOC on different projects related to digital infrastructure. The company has built a hybrid cloud for KOC to reduce the latter’s overall cost and allow them flexibility with the evolving technology.

Another area of automation is in the back-end processes, where GBM has developed applications using IBM technology to automate the processes for 17 departments. This will have an impact on operations and cost.