Intergraph helps plants tackle unstructured data

Intergraph helps plants tackle unstructured data

EVERYONE in the industry would prefer to run a plant they have been involved with from conceptual design to commissioning, all handled by a single EPC contractor who has handed over a perfect set of data files. However, in reality, most owner operators have to deal with plants which incorporate brownfield elements built in the past for another company, and usually poorly documented. Plant documentation is likely to be incomplete, unstructured and in a variety of formats. This introduces a range of operational, safety and financial risks. Consequently, software to structure and analyse such documentation is a valuable tool for brownfield site operators.

Incomplete, unreliable and unstructured plant data exposes the plant owner/operator to significant risks. It is difficult to analyse a problem on a plant or take a critical decision if inadequate information means unreliable design base documentations of critical systems on the plant.

Safety risks are even more important. If the owner does not know all the details of their plant, how can they guarantee it is safe and achieve their zero hazards goal? That requires detailed, up-to-date and easily accessible materials records.

DEALING WITH DATA

What is really needed is a single point of access to all plant data, be it historical about the brownfield elements, or created today, in any relevant data format. We need a tool to bring structure to unstructured information and make it manageable and accessible.

The key requirement is that the tool should help users find the information they need, even if initially they are not sure what they are looking for, or where to look for it.

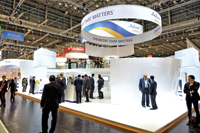

Intergraph Process, Power & Marine (PP&M), a major provider of engineering software for the design, construction, and operation of process plants, ships and offshore facilities, has developed the SmartPlant Fusion package to deal with unstructured information challenges.

SmartPlant Fusion is the latest solution developed by Intergraph to rapidly capture, organise, and make available large volumes of previously unstructured information through a simple web portal interface. The types of unstructured information include documents, drawings, 3D models, and even link to High Definition Survey (HDS) laser scans.

This ‘as-built’ information asset is vital but often undervalued representation of a plant. SmartPlant Fusion enables intuitive navigation with an accurate depicting of the as-built configuration of the plant, making unintelligent information smart.

QUICK BENEFITS

One of the first companies to benefit from SmartPlant Fusion is Woodside, the largest operator of oil and gas production in Australia, and also the country’s largest independent dedicated oil and gas company. It produces around 900,000 barrels of oil each day (bpd) from an extensive portfolio of facilities.

Intergraph was engaged by Woodside to help prepare the engineering scope for the Ngujima-Yin FPSO, which has a daily production capacity of 120,000 barrels of oil. The engineering information for Ngujima-Yin was found in multiple data sources, including several international locations. Data and documents were inconsistent and in different formats as they were managed differently at each location. There were also multiple versions of drawings and documents.

SmartPlant Fusion helped Woodside improve data and documents processing and analysis time, and it enabled the engineer to quickly search on a document and view every version before making an assessment.

The application also allows multiple users to work within the single master data source, eliminating errors from duplication or working on outdated versions. SmartPlant Fusion contains an integral web-based portal, providing project personnel remote access to live data during the project phase, an important requirement for major projects.

In a brownfield environment operators have to cope with the existing data, which is likely to be spread across a network. When first installed it should crawl through all the files in identified locations and then continue to monitor relevant folders to check if new files are added.

After the initial set up, an effective data management tool should immediately provide convenient access to the formerly unstructured plant data. This will save time and costs while improving safety and reliability.