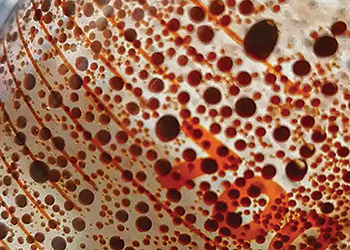

SRB colonies prevalent in crude oil

SRB colonies prevalent in crude oil

The first target in the development of a biological solution was the control of the SRB population

The chemistry of hydrocarbons has been researched in great detail since the oil age started in 1859 with a purpose-drilled well near Titusville, Pennsylvania. The knowledge gained led first to ever more sophisticated refineries.

Later issues such as dangerous H2S concentrations, high sulphur levels, decreasing API gravity and reservoir depletion developed into systemic problems. To fight against this creeping quality degradation, methods targeting some of them – with many deploying large amounts of chemicals – are in daily use these days both upstream and downstream.

As it is when dealing with symptoms without eradicating their root cause, the results vary and success is of temporary nature. And other problems, which can’t be addressed through chemicals, e.g. decreasing API gravity, are left unattended. In order to master the technical, ecological, and financial challenges the industry faces, a completely different way of thinking is required.

'We started out with taking a look from a different angle at petroleum and natural gas, trying to find answers to questions like ‘Why has a slight change of crude oil sulphur content such a big impact on API gravity?’. While empirical, tested mathematical relationships are available to calculate the numbers, the underlying questions remained unanswered to us. Thus, we had to find our own explanations. Along this journey, we adopted a view of petroleum and natural gas as a 'Hydrocarbon Based Ecosystem,’ pointing us towards a paradigm-changing direction for our solution,' says Rainer T Tesch, managing director, The Fourth Pyramid Company.

The key inhabitants of this special ecosystem are well known: sulphate deducing bacteria, or SRB.

|

|

Tesch ... a novel approach |

The control of the SRB population is the key to solving the above-mentioned issues. This turned out to be not an easy task – they have been around since billions of years and are perfectly adapted to their habitat and its physical parameters range in terms of temperature, pressure, chemical resistance, etc. This is confirmed by experiences observed in the field with biocide injections and the like: SRB always bounce back.

The first target in the development of a biological solution was the strict and permanent control of the SRB population. 'Once we had achieved this we could, e.g. in crude oil, reduce H2S concentrations from 2350 ppm to 15 ppm and extract sulphur, lowering concentrations from 2.3 per cent to 0.4 per cent.'

The second target was to find a way to repair as much as possible the impact the SRB activities have had on the hydrocarbons. 'We continued our research with the same focus on biological agents. Once we had accomplished this we could, e.g. in crude oil, increase API gravity from 24° API to 35° API and decrease viscosity (40° C) from 7.35 cSt to 1.33 cSt.'

The final step of the development process was to transfer the lab results into an industry-wide upscalable solution, which took most of last year. 'Now we can offer an additive that combines ancillary chemicals and custom biological agents in one ready-to-use liquid – made in Germany. It is non-corrosive, environmentally friendly and economically competitive as it replaces or minimizes the currently used chemicals (corrosion and scaling inhibitors, demulsifiers, viscosity improvers, etc.). And it adds value directly and indirectly through product quality improvements – no more H2S, higher API gravity, etc.

'In conjunction with our customised, simple application methodologies we are able to offer efficient package solutions to the industry, patent pending. Our technology can be applied in the reservoir, in upstream production facilities and downstream processing plants. And it works for both petroleum and natural gas,' he adds.