Dr Al-Faqeer ... welcoming competition

Dr Al-Faqeer ... welcoming competition

While Sadara has pioneered some of the speciality chemicals in Saudi Arabia, such as isocyanates and polyols, it recognises that the kingdom is becoming an increasingly competitive chemical marketplace, says Sadara Chemical Company CEO Dr FAISAL AL-FAQEER in an interview with K S SREEKUMAR

Continuing to look downstream towards enabling more end-user product manufacturing and attracting investors to the market will help Saudi Arabia lower its reliance on imports of those products and switch to in-kingdom provision and exports, says Sadara Chemical Company CEO Dr Faisal Al-Faqeer.

“This will help lower the premium costs associated with importing products and localise more the investment in products ‘Made in KSA’,” says Dr Al-Faqeer in an interview with OGN.

.jpg) |

Sadara ... making speciality chemicals |

“While Sadara has pioneered some of the speciality chemical sectors in Saudi Arabia, such as isocyanates and polyols, we recognise that the kingdom is becoming an increasingly competitive chemical marketplace, primarily due to the industrial move downstream that is central to the country’s national economic diversification under Vision 2030. We welcome this competitive environment, and we are confident that Sadara will thrive in this marketplace,” he says.

Excerpts from the interview:

What were the highlights of Sadara's performance this year?

In January, Sadara was awarded certification by the Saudi Customs Authority as an Authorised Economic Operator (AEO), in a global programme facilitating movement of the company's imports and exports. The Authorised Economic Operator programme, a component of the World Trade Organization (WTO) Trade Facilitation Agreement of 2017, seeks to build a partnership between customs and business enterprises that enhances the security of the global supply chain while providing more benefits to facilitate trade.

In March, Sadara broke ground on the EO/PO Pipeline Project, to provide Ethylene Oxide and Propylene Oxide feedstock to manufacturing facilities in PlasChem Park. This year, three companies broke ground on their PlasChem Park facilities: Surfactant Detergent Company, Halliburton and Baker Hughes.

|

Sadara has become a game changer in the chemicals sector |

In September, Sadara became the first Saudi Aramco joint venture to gain certification as a Responsible Care Company. Responsible Care is an international, voluntary initiative developed to drive continuous improvement and achieve excellence in environmental, health, safety and security performance by companies in the chemical industry. Sadara successfully completed a five-day external audit required for RC14001:2015 certification. Sadara is a signatory and active member of the Responsible Care Committee of the Gulf Petrochemicals and Chemicals Association (GPCA). This certification takes the company's operations to the next level of excellence and could not have been achieved without dedicated efforts from all who participated.

It's also worth noting that soon after the Responsible Care certification, we became the first Aramco JV to produce an annual Sustainability Report according to Global Reporting Initiative (GRI) standards.

What are your thoughts on the competitiveness of Saudi Arabia’s downstream sector?

While Sadara has pioneered some of the speciality chemicals in Saudi Arabia, such as isocyanates and polyols, we recognise that the kingdom is becoming an increasingly competitive chemical marketplace, primarily due to the industrial move downstream that is central to the country’s national economic diversification under Vision 2030. We welcome this competitive environment, and we are confident that Sadara will thrive in this marketplace.

What are the strategies that would help the region create more enduring wealth for chemicals?

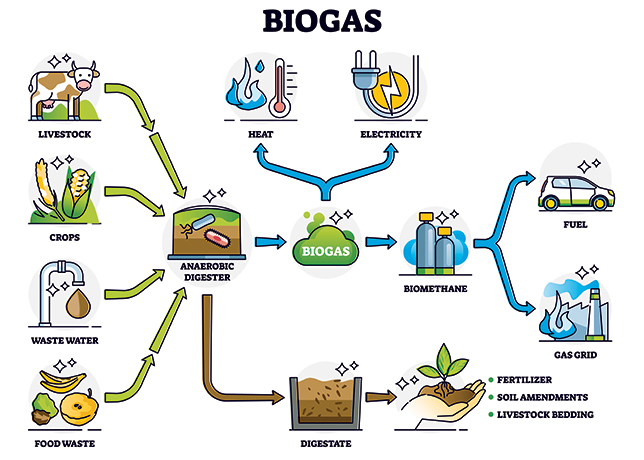

Clearly the chemical industry will benefit from the focus of the kingdom’s Vision 2030, which promotes the development of diverse manufacturing facilities that make use of various chemical products. For example, we at Sadara manufacture polyols and isocyanates, which are precursors for polyurethane foams that can be used in a variety of products, including automobile dashboards, furniture, mattresses and the like.

Continuing to look downstream towards enabling more end-user product manufacturing and attracting investors to the market will help Saudi Arabia to lower its reliance on imports of those products and switch to in-kingdom provision and exports. This will help lower the premium costs associated with importing products and localise more the investment in products “Made in KSA”.

How did the attacks on Saudi Aramco's facilities affect the feedstock availability for Sadara? How long did you take to claw back to status quo?

The interruption to Sadara feedstock supply from Saudi Aramco was very minor, amounting to an approximate average of 16 per cent in different proportions. This curtailment only lasted for short period of time (two weeks in total) and Sadara was able to maintain regular operations throughout this period.

What is the target date of completion for the Amec Foster Wheeler-designed ethylene oxide (EO) and propylene oxide (PO) pipeline project? What is the scope of the pipeline project? How will it contribute to the 12 sq km Plaschem Park?

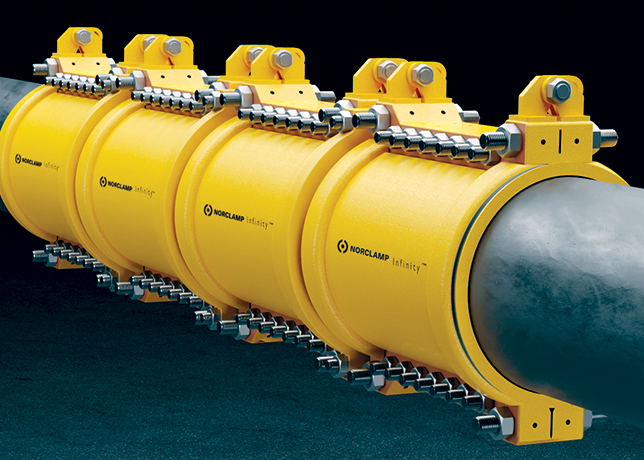

In May 2018, Sadara entered into a detailed engineering contract with Amec Foster Wheeler and Partners Engineering Co – Al Khobar for the design, engineering, material specifications and procurement for two 7-kilometre special material pipelines to transport EO and PO from Sadara plants to PlasChem Park. With the design phase completed, the EO/PO Pipeline Project, serving one of PlasChem Park's most attractive clusters, is continuing to move ahead on schedule. We broke ground on the project in March of this year. The EO/PO transportation system will be commissioned in time for the first wave of our EO and PO cluster investors and will provide a strong incentive for similar investors to locate in PlasChem Park. The pipeline system will be second to none in the entire Mena region.

PlasChem Park is a key element differentiating Sadara from other petrochemical, chemical and plastics manufacturing projects in Saudi Arabia. It is uniquely positioned to enable and support downstream opportunities in many market segments, including the Hydrocarbon Resin Cluster, Ethylene Oxide/Propylene Oxide (EO/PO) Cluster, Polyurethane Cluster and a Plastics Cluster.

This year three companies broke ground on their planned manufacturing facilities for PlasChem Park: Surfactant Detergents Company, Halliburton and Baker Hughes.

How much of your target for investments in the PlasChem Park have been achieved?

As you know, PlasChem Park is being developed by the Royal Commission for Jubail and Yanbu with the support and cooperation of Sadara. We are very pleased with the ongoing progress in the development of the park.

.jpg)