Alderley's smart metering system makes real-time assessment of assets

Alderley's smart metering system makes real-time assessment of assets

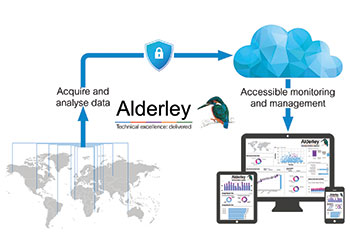

The Alderley Smart Measurement Integrity Management system gives operators complete certainty and control over their measurement system’s performance, wherever they or their assets are in the world, Mike Shepherd, Business Development Director at Alderley, tells OGN

A key challenge for all businesses is the restriction on local and international travels. This continues to be a necessary barrier to help reduce the spread of Covid-19.

However, in many industrial applications this has highlighted the dependency of onsite personnel to monitor and maintain assets.

"Digital has long been on the agenda for many sectors. The advent of Covid-19 has reinforced and expedited the need for digital adoption. The energy industry is a perfect example of this," Mike Shepherd, Business Development Director at Alderley tells OGN.

Energy producers, and in-particular oil and gas operators, use sophisticated metering and measurement systems to determine the quantity, quality, efficiency and value of their energy.

Acting as the cash register of the energy industry, the performance of these production critical systems is paramount. Even the smallest unmanaged change can have a significant impact on a company’s operational and financial performance.

Measurement systems are, therefore, closely managed by skilled engineers typically performing routine, time-based maintenance activities onsite.

Despite this being the standard maintenance model for the past over 50 years, this process is often inefficient and outdated compared with practices in other industries, for example, automotive and aviation.

Routine maintenance activity can only assure performance at the point of assessment. This creates two sub-optimal scenarios: If the asset is performing as required, then the mobilisation and costs are unnecessary; and if the asset is not performing as required, then how long has the instrument been displaying drift, and what are the environmental and financial implications as a result?

In addition, energy producing assets are often situated in remote and/or hazardous areas. This means that engineers who are either retained onsite or mobilised to the site will incur high costs and an increased risk of personal injury. With safety a mainstay in all major operator’s objectives and with an increasing focus on efficiency — both from an environmental and economic perspective — this is not the most effective use of resource.

As a globally renowned provider of industry-leading fiscal metering and control systems and measurement software, Alderley has developed a smart solution for this scenario.

The Alderley Smart Measurement Integrity Management system gives operators complete certainty and control over their measurement system’s performance, wherever they, or their assets are in the world.

Utilising connected devices, secure cloud-platform technologies, specialised uncertainty algorithms and intuitive dashboard tools, the Alderley smart solution enables the centralised monitoring of asset integrity and performance, and the scheduling of maintenance only if and when it is required.

Central to the effectiveness of this solution — and the functionality that makes it smart — is the ability for the system to quantify the significance of a change in measurement performance, including its potential financial impact.

It achieves this by dynamically assessing the real-time uncertainty of an operator’s measurement system — at a corporate, system and granular instrument level — and quantifying its drift when an event or change in performance occurs.

This ability to quantify the drift and subsequently calculate the financial exposure is essential for truly informed remote operations; giving operators the ability make informed decisions about the scheduling and prioritisation of resource.

Furthermore, the condition-based monitoring functionality of the Alderley smart system supports the early detection and prevention of potential faults to maximise uptime. And in the event of failure, the system’s deep-dive capabilities allows the operator to pinpoint the poorly performing or failed instrument and system, conduct remote troubleshooting actions and, if required, relay detailed diagnostics to the mobilised maintenance team to optimise the efficiency, effectiveness and safety of the resource.

With Covid-19 seemingly here to stay (at least, in the short-term) and remote working becoming more the norm, the Alderley Smart Measurement Integrity Management system can continue to give operators the assurances they need in their measurement system — and to greater effect — in this new normal.