Alfa Laval's free rotating rtractor

Alfa Laval's free rotating rtractor

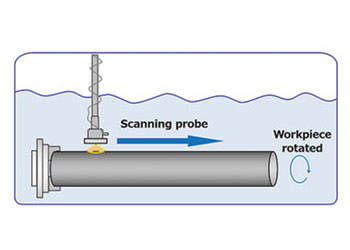

Alfa Laval has launched a new free rotating retractor, a high-efficiency retractable cleaning device that provides complete cleaning assurance, enhancing product safety while boosting uptime and productivity.

It addresses the uncertainty faced by manufacturers in cleaning confined spaces like ducts and tanks.

The free rotating retractor is the latest example from Alfa Laval that makes 100 per cent cleaning coverage in hygienic processing lines, like milk or infant powder plants, and other processing industtries a reality.

"It is a dynamic and resource-efficient device for quickly and economically cleaning hygienic ves-sels. It remains sealed off from the product area during production, flush with the vessel wall. The spray head sprays cleaning media in a 310-degree-up pattern, retracting after cleaning," says Babak Shojaei, Manager, Product Management, Tank Cleaning, Alfa Laval.

It effectively removes residues from hard-to-clean vessels, minimising cross-contamination and increasing productivity. It complies with FDA, EU, and China regulations.

This dynamic cleaning device offers 35 per cent water, chemical, and time savings per CIP cycle, enhancing sustainability in manufacturing operations and resource efficiency.

It is a cost-effective and easy-to-maintain cleaning device that can be fully automated by pairing it with an existing CIP system.