Petrokemya ... increasing output

Petrokemya ... increasing output

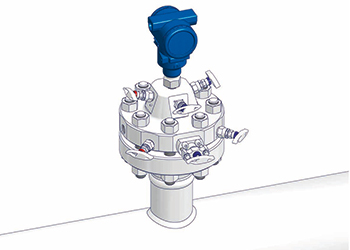

In addition to capacity expansions, Sabic is also investing in world-class technology

In light of dynamic industry trends and rapidly changing technologies, Sabic has announced a number of investments that will drive operational efficiencies, increase capacity, leverage world-class technology, and convert insights into solutions for the industries it serves.

"We are laser-focused to deliver on diverse customer needs," says Ernesto Occhiello, executive vice president, Sabic’s Innovative Plastics business. "We believe that to effectively support global customers for years to come, we must have the vision and commitment to continuously reinvest in new technologies and efficient processes, even during the most challenging of times."

Over the next five years, Sabic will add a total of 338 kilotonnes of capacity across its entire global portfolio. For polycarbonate alone, Sabic plans to bring on line nearly 35 per cent of the world’s publicly announced capacity expansions as part of its joint venture with Sinopec in Tianjin, China.

The company’s Petrokemya facility will increase its annual ABS production by nearly 80 per cent when it comes on line later this year. Sabic has also announced a 30 per cent phased increase in its global Ultem resin capacity over the next five years, while evaluating additional opportunities for further Ultem resin expansion.

"These expansions are consistent with our history in Brazil where we have expanded local production by more than 60 per cent over the last decade," says Ricardo Knecht, director, South America sales for Sabic’s Innovative Plastics business. "We’re investing to ensure we are as competitive and sustainable as we can be, while converting our deep understanding of industry trends and resulting customer challenges into solutions that address their exact requirements."

In addition to capacity expansions, Sabic is also investing in world-class technology to translate industry insights into solutions designed to meet the more sophisticated and rapidly evolving requirements of today’s customers.

Most recently Sabic announced that it is leveraging its global technology centers in the Americas, Europe, Asia and Saudi Arabia to expand the company’s application development focus in additive manufacturing technology.

Sabic’s capabilities and experience in additive manufacturing across a number of industries will enable it to work closely with technology innovators including universities, research laboratories, printer manufacturers, OEMs and emerging technology companies to help accelerate the advancements necessary for additive manufacturing to reach its full potential.

When converting industry and customer insights into solutions, Sabic leverages six key innovation capabilities:

• Collaborative Innovation: Collaborates with customers, industry designers and academia to help develop the right solutions faster and better;

• Concept Generation: Views customer challenges from new angles by developing geometric representations of innovative ideas and potential solutions;

• Material Science and Chemistry: Draws upon Sabic’s rich science and technology know-how to help develop new material solutions and to improve existing ones to better answer industry needs;

• Process Technology: Performs state-of-the-art thermoplastic processing development to evaluate a solution’s feasibility and then implement on a production scale;

• Part Design and Predictive Engineering: Utilises software tools and engineering expertise to help virtually design and test parts to help customers minimise development costs and achieve competitive differentiation; and

• Sustainability and Life Cycle Management: Performs product life cycle evaluations to suggest material candidates, design, processing and end-of-life treatment options to help customers achieve sustainability objectives.

Sabic has 19 dedicated Technology & Innovation facilities around the globe.