Bahrain-based SNSI and Gerotto, a market leader with its highly technological machines from Italy, have joined hands to bring to the region innovative technology that guarantees remarkable advantages compared to traditional techniques

Quality of life is an elusive idea. Many equate it with wealth, but it doesn’t address everything one wants such as one’s physical and mental health. By providing man with ways to control uncertainties, technology has allowed him to increase the quality of his life in the practical sense of the term.

Being in the 21st century when people are given the possibility to assemble their own robots to increase their life quality, it becomes irresponsible and completely unnecessary to expose people to dangers and risks, while executing Industrial activities in confined spaces, when several non-man entry systems are available on the market.

Confined spaces are sometimes accessed for inspection, maintenance, or repair purposes. A confined space is an area or place where a person cannot enter nor exit in a natural or common way. Limited entry and egress areas are not suitable for human beings, because they create unavoidable exposure to danger and risks.

Confined space accidents are of particular concern in occupational safety and health due to the hazards that they pose to the victim and subsequently to a rescue team. Confined space training outlines the skills and protocols for safe entry, and includes precautions such as locking and tagging out connecting piping, testing of breathable air quality, forced ventilation, observation of workers in the space, and a predetermined rescue plan with appropriate safety harnesses and other rescue equipment standing by.

Remotely operated vehicles were demonstrated since the late 19th century in the form of several types of remotely controlled torpedoes. Nikola Tesla publicly demonstrated a wireless-controlled torpedo in 1989.

The use of a remote control to operate a robot eliminates the need for the operator to be in direct contact with a potential danger while executing industrial activities. This means the operators can position themselves in an area, away from moving parts, harmful dust, noise and vibration or falling debris that may occur. Operating by remote control also allows the operator to move more freely, enabling him/her to gain the best view of the work being performed.

Bahrain-based Sarens Nass Smet Industries (SNSI) a leading manufacturer of high performance vacuum loading equipment and Gerotto, a market leader with its highly technological machines from Italy, have joined hands to bring to the region innovative technology that guarantees remarkable advantages compared to traditional techniques.

SNSI and Gerotto combine manufacturing expertise, market knowledge, and regional application to design and develop specific products that will help companies engaged in industrial cleaning activities to replace humans with robots to perform dangerous cleaning and digging works, in mines, refineries, industrial plants and many more confined areas where human entry is not safe.

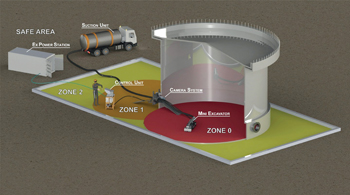

This partnership combines SNSI’s branded product 'The fluid Vacuator', in regional terminology the super suckers, for interventions with Gerotto’s Mini Excavators, Suction Excavators and Industrial Aspirators that considerably expand the range of interventions that companies engaged in industrial cleaning activities in the region could engage in. 'We have also realised a whole range of explosion proof products (with ATEX certification) for working safely in high explosion-risk areas,' says a company spokesman.

'With mines, refineries and petrochemical plants putting greater emphasis on health and safety as well as cost effectiveness, our robotic technology will ensure reduction in time required to perform tasks thereby reducing costs; and ensure that certain tasks could be executed under normal production circumstances without any need for a shutdown,' he says.

Innovative technology like robotics will determine the future of the industrial cleaning activities as it meets these changing requirements, elevates the cleaner to a machine operator, creates improvising ability, logical thinking, awareness and avoids exposure of people to dangerous working conditions.