Vertechs Wizard Frac Seat

Vertechs Wizard Frac Seat

The completion efficiency of unconventional wells can be improved with optimal dissolvability and design structure of dissolvable frac plugs, writes Jack Wang, Product Development Engineer, Vertechs Oil & Gas Technology

Casing deformities and slow mill-out runs greatly reduce the efficiency of well completion, increasing overall costs and delaying wells from producing. These problems are extremely common in China, the Middle East and Argentina.

Before dissolvable technology was introduced and implemented in plug and perf operations, operators heavily relied on cast iron and composite frac plugs. These tools can be reliable and cost-effective, but they can be extremely difficult to remove from the well in the case of downhole restriction or mill-out run. You might ask why composites are difficult to remove? Aren’t they designed to be milled out within 5 to 15 minutes, like many suppliers claimed?

CASING DEFORMITY ISSUES

A lot of factors can cause casing deformity that prevents a smooth plug and perf run, such as formation stress change during fracking, poor cementing quality, mechanical damage during running and more.

Most of the time, we don’t know if there is a downhole restriction, even until we have pumped down a plug that hits something and gets the bottomhole assembly (BHA) stuck. It is only later that we spent hours and days getting the BHA unstuck, flush the well and run coiled tubing to remove the plug and to confirm the severity of the restriction.

It normally takes up to 2-3 days to retrieve the stuck BHA. But if wireline gets snapped from the BHA while trying to pull it out, then a fishing operation must be arranged, exposing it to uncontrollable risks and delaying wells from production. Calling in another wireline crew to work on other wells on the pad will increase overall completion cost, and face the uncertainties of operation risk. Such decisions are, therefore, not to be made lightly.

MILL-OUT RUN LIMITATIONS

Based on statistics, it normally takes up to 25-60 minutes to mill out a composite frac plug in the south-west region of China. There are many factors for such extended mill-out time.

Firstly, the size of coiled tubing used in China is only 2 inches. This is due to the transportation limitation for oversized vehicles in mountainous terrain. Due to the restriction of size and weight, 2-inch coiled tubing is the best we can get here.

Secondly, limited by size, the choices for aggressive motors and mill shoes are also limited. High downhole temperature and chloride concentration impairs the viscosity of gel sweep, affecting cutting carrying ability. And the circulating rate will also be relatively lower.

Thirdly, the length of these frac plugs are quite long (sometimes over 20 inches). This means a lot of cuttings are produced during mill-up. So the coiled tubing crew is required to make short trips after milling every three frac plugs, to assist getting the cuttings out of the well and to prevent cuttings from filling up the annulus.

Combining all these factors, the overall mill-out efficiency is greatly reduced. Now imagine doing all that with multiple downhole restrictions in long horizontal laterals. To make matters worse, what if these plugs aren’t composites at all?

For the past few years, operators have desperately turned to dissolvable technology to resolve these challenges. Dissolvable frac plugs have with time replaced the majority portion of cast irons and composites from the market, reducing mechanical intervention hours and costs, bringing more wells into production at an unseen rate.

PURSUIT FOR EFFICIENCY

As I mentioned in another article, ‘Overcoming Learning Curve Leads to Successful Deployment of Dissolvable Plugs in Chinese Shale’, balancing the scale of mechanical properties and dissolvability is the key to construct a qualified dissolvable frac plug.

Although these dissolvable frac plugs have successfully addressed the above challenges, there is still a lot of room for improvement. Since some dissolvable frac plugs on the market still inherit the same traditional structure design of cast iron and composite frac plugs, they tend to be long and made up of many parts.

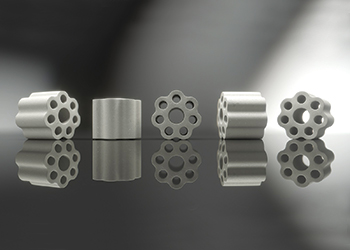

In order to improve efficiency, the dissolvability of these new plugs needs to be improved. This is called ‘Frac Seat’. Improving dissolvability simply means less materials used to construct the plug, and less materials to be dissolved downhole. The larger the surface contact area with wellbore fluids, the more thorough the dissolution.

Compared to traditional frac plug structure, the newly designed structure is 60 per cent shorter in length with 50 per cent larger ID once it is set inside the casing. And without compromising its anchoring and sealing abilities, the pressure rating of 70 MPa is still a certain feature. By compacting the structure, parts such as upper slips, upper cone and back rings are removed thus reducing the length of the mandrel that is required to support them.

If we run them separately and compare the end results (old structure versus new structure), assuming both plugs are constructed with the same dissolvable material composition for a specified downhole condition, the dissolution rate will be identical.

But the new structure features will greatly improve the dissolvability by reducing total body mass and increasing surface contact area with wellbore fluids. This will result in a much shorter total dissolution process, leaving zero debris downhole.

In early 2019, Wizard Frac Seats were deployed in several major shale play regions in North America and China.

With 70 MPa pressure rating and improved dissolvability, it ensured successful frac jobs and smooth clean out runs all the way to TD in multiple high temperature applications, reducing completion time and overall costs. Furthermore, it was also implemented in north-west region of China, where downhole temperature of 100 deg F can be extremely challenging for dissolvable completion tools.