Smart PFM Oil in water analyser using microscopy

Smart PFM Oil in water analyser using microscopy

In a white paper, Rivertrace offers ship owners guidance on the different optical technologies available and how to choose the best solution for their application

Rivertrace, market leading maker of smart water quality monitoring equipment, has cautioned ship owners confronted with a choice between several different sensor technologies suited to specific applications from selecting inappropriate oil-in-water monitoring technologies, which can jeopardise environmental compliance.

It has published a white paper intended to help ship owners understand the optical technologies available and choose the best solution for their application. The paper provides a simple description of each technology along with the advantages and disadvantages for each and a set of criteria for suitable applications.

Oil-in-water monitoring on ships is needed to comply with MARPOL measures for the prevention of oil pollution as well as in several other areas. Stringent measures governing oil pollution require that if monitoring is not effective, discharges cannot be carried out – providing a significant operational incentive for ship owners to select the right technologies.

Mike Coomber, Managing Director of Rivertrace says: "Oil-in-water monitoring is used in a wide array of marine and industrial applications and it is crucial that operators know which technology is the most appropriate for their purposes. Rivertrace’s foundation in research and development across all these solutions means we can offer a balanced view based entirely on customer needs."

Ship owners have four optical technologies to choose from:

Scattered light monitoring measures the amount of light that is scattered by oil particles in water to measure oil content. This is a well-proven, robust, and cost-effective sensor technology that is deployed in multiple solutions, including those monitoring oil in bilge water or ballast water discharge.

Absorbance sensors measure oil concentration based on the principle that different particles absorb light of different wavelengths. Monitors use multiple wavelengths to identify solids and oil particles. The technology is particularly effective where oil types are not known and works well even with turbid water. It has often been used in offshore production facilities.

Fluroescence sensors identify the presence of a specific oil type by measuring the light that particles give off when exposed to light of a particular wavelength. This technology is ideal when very low concentrations need to be detected, such as monitoring scrubber wash water discharge.

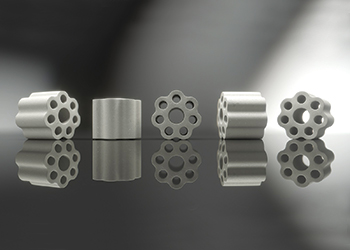

Microscopy technologies use the size and number of particles to visually identify oil concentration. Images from a high-speed camera are analyzed against a predefined library which can distinguish between oil, gas and solids. This technology is useful when dealing with unknown oil types and does not require calibration. It is well suited to monitoring oily water discharge from ships.

Coomber says Rivertrace is well positioned to offer guidance, deploying all four technologies across a wide range of monitoring equipment. The company has also played an active role in developing oil pollution monitoring regulation in the marine sector. As a result, the company understands how each technology can be best applied to help ship operators achieve environmental compliance.

Rivertrace’s expertise is underpinned by an internal research and development team dedicated to continually developing its existing products. Its engineers can draw on experience gathered from more than 30,000 monitors and systems installed worldwide, as well as working with a client list that includes leading separator manufacturers and many leading shipping, offshore oil and gas and land-based industrial companies.

Rivertrace’s white can be accessed at: https://rivertrace.com/customer-area/file/my-files/2020/04/24/white-paper-choosing-the-right-technology/

Rivertrace is an ISO9001 quality-assured company and market leader with over 30 years’ experience of oil-in-water monitoring. Headquartered at a 10,000-sq-ft facility, which incorporates a production factory in Redhill, 20 miles south of central London, the company has actively developed a global presence covering 32 countries, serviced by 28 technically trained distributors and agents.