Continuing the series on the importance of oil cleanliness for equipment, leading hydraulic solutions provider in the Middle East MH HYDRAULICS details the best ways to prevent oil contamination in its Tech Talk No 2.

The most common channels for oil contamination in equipment are:

• New oil, which in almost all cases is not totally clean;

• Inlet and outlet vents, filling ports, breathers of hydraulic systems, gearboxes, pumps; and

• Hose replacements.

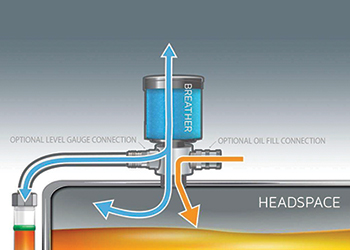

Equipment breathes when the oil level fluctuates in the tank; and there are temperature fluctuations – air will be sucked in when the temperature in the headspace drops (usually at night).

Thus, when air flows into the asset and this air is contaminated with small particles and moisture/ humidity, the hydraulic oil/lubricant will get contaminated. Humidity will turn into condensation, which will cause surface corrosion in the headspace and water droplets will fall into the hydraulic oil/lubricant.

Therefore 'headspace management' is very important to keep the oil healthy. This is where desiccant breathers from Des-Case RMF Systems - a market leader and manufacturer in filtration products and desiccant breathers from the USA and the Netherlands - come into their own. Des-Case breathers work both ways, when inhaling and exhaling they absorb the moisture in the air, thus, minimising condensation in the head space.

Desiccant breathers work not only to prevent moisture from getting in, but they are actively dehydrating the headspace, resulting in dryer oil. They also prevent small particles (3 micron and above) getting into the oil. Desiccant breathers can extend machine component life by three to eight times.

In addition, to minimise the possibility of air contaminants from entering the system, filling ports must be modified to allow oil to be added without exposing the machine to the ambient environment. The easiest way to achieve this is by using quick-connects and custom adapters that replace conventional fill ports.

So how do desiccant breathers compare with common OEM breathers and what are the advantages of installing the adaptor kits?

The technical article in our online edition (https://www.ognnews.com) provides the details.