Kanoo ... leading investments

Kanoo ... leading investments

After years of partnership between the companies, the assembly and production of Shutter Valves in Saudi Arabia is not only a natural next step, it also makes sense to have the valves manufactured, assembled, and serviced closer to customers in the region

The strong partnership between Yusuf Bin Ahmed Kanoo Group (YBA Kanoo) and US-based Clarke Valve, manufacturer of the proven precision control Shutter Valve, is seeing a natural progression. The companies are actively coordinating to build a production line of Shutter Valves in the Kingdom of Saudi Arabia (KSA).

YBA Kanoo is the exclusive representative of Clarke Valve in the GCC, selling and servicing all Shutter Valves in the region. The company also acted as the lead investor in Clarke Valve’s recently completed Series C financing, further strengthening their relationship.

"The assembly and production of Shutter Valves in KSA is, therefore, a natural next step in our ongoing relationship. It also makes sense to have our valves manufactured, assembled, and serviced closer to our customers in the region," Kyle Daniels, President and CEO, Clarke Valves, tells the OGN.

|

Daniels ... design perfection |

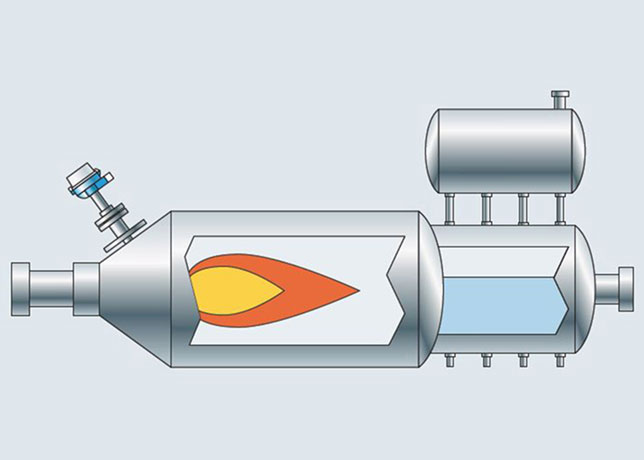

The Shutter Valve is claimed to be the world’s most compact and efficient control valve, with the same face-to-face dimensions and valve characteristics of globe valves at a fifth of the size and weight.

"If you look at the before and after picture (Figure 1), you will see what we mean. Clarke Valve meets ANSI B16.34 wall thickness requirements throughout the Shutter Valve product line for each appropriate pressure class, while these valves weigh only 1/5th of what competing globe valves weigh. This weight difference is due to the Shutter Valve’s unique geometric configuration, which still utilises all of the same materials and manufacturing processes as other valve types," says Daniels.

Having the exact face-to-face dimensions as traditional valves allows for no modifications required during installation, ensuring a cost-effective and straightforward switch.

The Shutter Valve derives its design from aerospace industry techniques for fluid control, sealing, and mechanical systems. It was engineered to be bubble-tight, compact, precise, low-torque, inexpensive, and premium quality for easy maintenance and improved uptime. "We wanted to create the perfect valve for customers that demand precision flow processing and a low total cost of ownership," says Daniels.

|

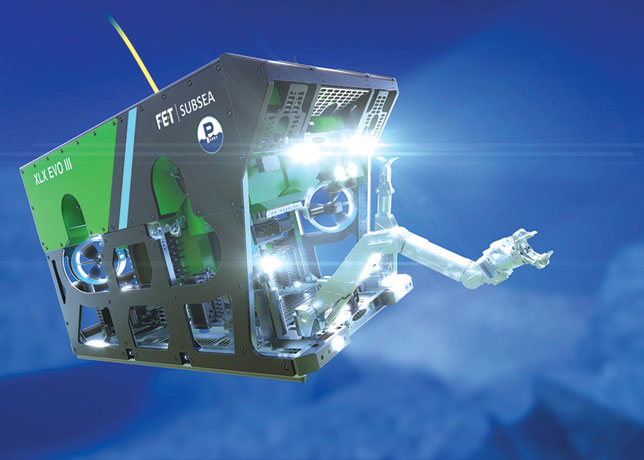

YBA Kanoo's valve facility |

The valve’s design features a continuously centralised flow path, providing virtually no noise or cavitation. The petals that open and close the valve’s orifice allow for a smooth, predictable pressure drop, while the centre notches of the petals protect the seals and provide a tight shutoff.

The aperture also creates a centralised flow stream that can range anywhere from a fine mist to a wide-open port, resulting in certified 500:1 rangeability. This rangeability is, on average, 10 times more than what is offered by globe valves.

Also, the curved petals operate perpendicular to the flow, reducing the required torque of the valve. This allows the customer to use electric automation, reducing overall automation costs.

The Shutter Valve recently received the API 607 Fire Test certification, meaning it withstood a fire of 750–1,000 deg C (1,350-1,800 deg F) for 30 minutes at 75 per cent of the maximum working pressure, with zero leakage from the shell, and only 4 mL/min leakage at the stem.

Daniels says the Shutter Valve is the first and only control valve to meet the US Navy specification MIL-DTL-32632. "This specification establishes the criteria for the design, materials, and functional capabilities of all ‘dilating disk’ valves for flow control of naval shipboard water, oil, and gas service. Meeting the NAVSEA Spec aligns the Shutter Valve with the US Navy’s goals of reducing weight and increasing efficiency in their valve systems to meet fleet modernisation goals."

YBA KANOO DIVERSIFICATION

|

Figure 1: The globe valve (left) replaced by the Shutter Valve (right) |

Early this year, Clarke Valve completed the sale of multi-million Series C Preferred Stock. This round was led by YBA Kanoo, with the manufacturer’s existing strategic investors, such as Saudi Aramco, Chevron, and Climate Investments also participating.

"Their investments clearly show their belief in our technology and the value that our innovation brings to the market. This funding provides Clarke Valve with operating cash and strengthens our balance sheet. It also allows us to invest heavily in scaling our business and innovating in an industry that has not experienced significant innovation in over 50 years," says Daniels.

YBA Kanoo has always been at the forefront of forming successful joint ventures and setting up local manufacturing since the last 40 years with reputed partners like Halliburton, Akzo Nobel, BASF, etc to name a few, according to Ali Abdulla Kanoo, President, Kanoo Industrial & Energy.

He says: "We are continuing our efforts to diversify further and contribute to the In-Kingdom Total Value Add (IKTVA) programme as best as we can. We started off with a meagre score of 14. But with the patronage of and directions from Saudi Aramco and government support, we take pride in announcing our latest IKTVA score of 49. But we are working to improve that further."

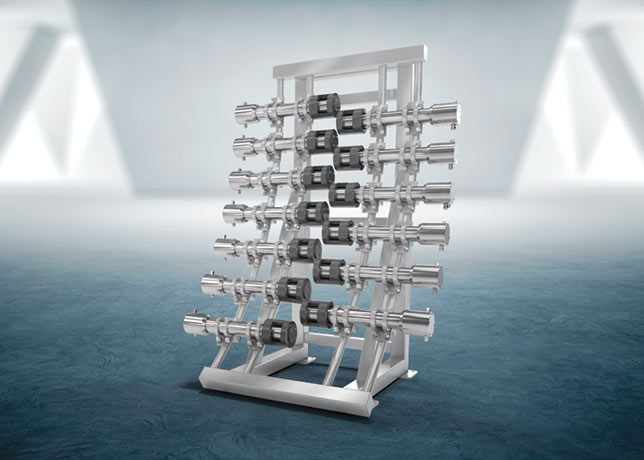

A few years back, YBA Kanoo set up its safety valves manufacturing facility in-Kingdom. It then extended that to pressure vacuum valves in its existing unit in Dammam for valve assembly and repair. From this facility, the company has produced over 3,500 units and supplied to major clients like Saudi Aramco, Sabic, Saudi Electricity Company (SEC), Ma’aden, Sadara, Satorp and others.

"We extensively supply to greenfield projects throughout the Mena region working through multinational EPCs like Saipem, McDermott, Technipfmc, CB&I, Tecnicas Reunidas, SNC Lavalin, ENPPI, EPPM, JGC, etc," says Kanoo.

A new facility has now been added in the Royal Commission, Support Industrial Area 3, Jubail. Spread over 8,500 sq m, the state-of-the-art facility is equipped with latest testing, machining and repair equipment procured from globally reputed suppliers and trained technicians, and will cater to manufacturing and servicing of Clarke control valves amongst others. Besides the safety valves and breather valves, Kanoo says they are adding new assembly lines for various other valves as part of their manufacturing expansion of local content and IKTVA plan. These include:

• Lubricated plug valves with license agreement from Brdr Christensen, Denmark, which is already in the process of approval from Aramco.

• Shutter Valves from Clarke Valve, US.

• Future addition of many other niche market valves for the oil and gas industry.

• Moving to manufacturing of valves from component/casting level, to be machined/sourced locally in-Kingdom and aim at valve automation very soon.