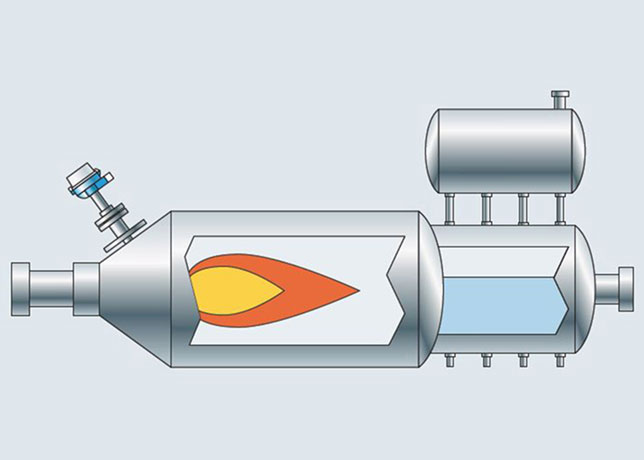

The increased focus on climate change has resulted in more intense scrutiny about how the oil and gas industry can overcome the significant challenges of fugitive emissions and leak detection and repair (LDAR). Valve stem leakage is a key contributor to fugitive emissions, says Kyle Daniels, President and CEO, Clarke Valves, adding valve stem leakage from globe type and other legacy valves account for over 60 per cent of refineries’ fugitive emissions, according to the US Environmental Protection Agency (EPA).

He says: "The current response to dealing with valve stem leakage is to have technicians routinely tighten packing followers. While this does marginally reduce emissions, it also increases torque requirements and total energy consumption."

But the Shutter Valve addresses this market challenge head-on, with an extremely reliable stem seal technology that reduces fugitive emissions by 98 per cent and doesn’t require increased torque, operating energy, or frequent physical retightening of the stem packing.

"Clarke Valve’s Shutter Valve earned its ISO 15848 fugitive emissions certification by allowing only 2 ppm methane leakage. In comparison, the typical ‘low emissions’ globe valve releases 100 ppm," he adds

Furthermore, the Shutter Valve can play two crucial roles in the shale sector, as it gains traction in the region: reduce cost and increase performance.

"With a low initial cost and minimal maintenance costs, the Shutter Valve is uniquely positioned to deliver superior value to the cost-sensitive shale sector. In terms of performance, the valve’s patented geometric petals provide a centralised flow path through the valve, allowing for precise flow rate stability. The Shutter Valve’s flow rate stability eliminates the need for valve ‘hunting’ through flow rates that typical globe valves struggle to maintain," says Daniels.