The DCZ series of DBB valves are designed with a large 14 mm bore

The DCZ series of DBB valves are designed with a large 14 mm bore

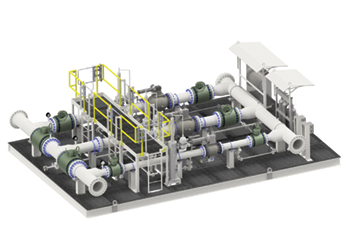

AS-Schneider valves are being successfully used at Oman’s Amal oilfield, which uses steam generated at the Miraah solar thermal facility, to boost production with a lower carbon footprint

Boosting recovery from aging oil fields is a major challenge in oil production. As production starts to taper off, oil companies must employ enhanced oil recovery (EOR) techniques.

By using EOR technology, production can be increased to keep the field economically viable.

EOR methods can help extract up to 60 per cent of a reservoir’s oil as compared to 40 per cent using primary and secondary extraction methods.

In the Middle East, steam injection has been successfully used as an EOR technique for the recovery of heavy viscous oil.

|

|

The traditional method of steam generation |

In this method, high temperature steam is injected into the well to heat up the subsurface oil. The oil production from a heated well increases due to the effects of lower viscosity, vapourisation and thermal expansion.

Traditionally, natural gas is burned to produce the EOR process steam. The oil and gas industry, however, is under increasing public and regulatory pressure. Worsening climate change blamed on greenhouse gas emissions from the use of its products, and the additional use of fossil fuel, during the extraction process, exacerbates the environmental concerns.

Compared to the traditional method, solar thermal energy for steam generation is a clean and environment-friendly alternative to burning natural gas.

This method uses mirrors to reflect and concentrate solar radiation on to receivers that convert solar energy to heat. The clean energy is then used for the EOR process steam generation.

The solar thermal approach not only reduces the carbon footprint of the extraction process but also lowers the cost of extraction.

An increasing number of Gulf state oil companies are working on replacing natural gas-based steam generation, and have included a solar steam process as part of their environmental agenda.

A prime example is the solar steam generator at Oman’s Miraah Solar Plant, one of the largest solar plants in the world.

Boasting a solar thermal capacity of 1,021 MW, the plant has a daily steam output of up to 6,000 tons. That translates into annual gas savings of 1.6 TWh and annual CO2 emission savings of 300,000 tons.

|

|

AS-Schneider DBB valves have a standard rating of 420 bar |

The 6,000 tons of solar steam generated daily at Miraah constitutes a substantial portion of the EOR steam requirements at the Amal oilfield operated by Petroleum Development Oman (PDO). The steam EOR increases the well productivity at Amal by 300 per cent.

The design temperature for steam injection wells is typically in excess of 400 deg C. At these high temperatures, the hardness of the valve material is reduced and its fatigue-resistance is compromised. Small cracks may appear which can propagate across the section causing failure.

Valves with O-rings and thermoplastic seals are unsuitable for use in this temperature range. High-temperature, high-pressure applications demand that valves have a specialised design and construction.

Metal-to-metal seated ball valves, with a larger bore and fire safe graphite sealing, are generally used as isolation valves in steam EOR application.

These valves are constructed from special alloys and are protected with a heat, corrosion and wear-resistant coating/cladding, applied using a specialised process.

Some valve manufacturers can take several weeks to supply such valves.

A ball-set (ball + seat) must be ordered from third-party suppliers. And in the event of an unplanned shutdown, procurement and replacement of these special purpose valves can become a challenge for the maintenance team.

The cost of using these valves can be high both, in terms of the procurement cost, and the production loss suffered while waiting for a replacement to arrive.

Furthermore, maintenance and safety protocols demand periodic service and replacement of critical valves.

DOUBLE BLOCK AND BLEED VALVES

Traditionally, metal-to-metal seated ball valves have been used for high temperature applications. These valves can be difficult to procure as they are made from special alloys and require a specialised coating process.

Also, in steam injection wells, pressure transmitter/pressure gauge (PT/PG) isolation valves are of critical importance.

Based on customer demand, AS-Schneider has developed a bigger bore globe type needle valve in double block and bleed (DBB) configuration that is ideally suited to this application.

DBB valves are used for controlling process flow to allow for maintenance, sampling, and flow diversion.

These valves have two seating surfaces which isolate pressure at each end. It includes a provision for venting/bleeding the cavity between the two seats.

In addition to providing safety against pressure at both upstream and downstream ends, DBB valves help isolate instrumentation such as pressure indicators and lever gauges.

They help prevent product contamination, allow removal of instruments for calibration, cleaning or repair, and simplify product sampling.

The bleed valve is used to relieve pressure which can build up due to thermal expansion of the fluid in the cavity. It helps prevent over pressure which can lead to leakage or rupture.

For high temperature and pressure applications, such as steam EOR, AS-Schneider offers the DCZ series of DBB valves.

These valves are designed with a large 14 mm bore, needle type block in DBB configuration that is rated up to 550 deg C. It is a compact and tough design built to last in extreme applications.

The innovative design of the valve head allows smooth low-torque operationand gives the valve a long service life.

The standard rating of AS-Schneider DBB valves is 420 bar but valves can also be produced with a 689 bar rating for high-pressure applications.

The series contains monoflange and dual flange models with specialised process and instrument designs. The valves are readily available from the company as they are faster to produce and do not require special third-party components.