Hong ... rethinking RO plants

Hong ... rethinking RO plants

RO plants can be powered as stand-alone facilities and can produce carbon neutral water if run on renewable power thus overcoming thermal plant challenges, Jong Myong Hong, VP, Engineering Technical Services, Engie, tells OGN

Desalination is a separation process that is used to reduce the dissolved salt content of saline water to a usable level.

Desalination can be done either through a distillation process (which is akin to boiling water and collecting the steam through evaporation) or by a reverse osmosis (RO) process, which is done using a spiral wound polyamide membrane.

In the UAE, 83 per cent of desalinated water is produced at thermal plants.

The thermal desalination plant is usually coupled with the thermal power as a cogeneration plant to enhance the overall fuel efficiency by using the low-pressure steam left after producing power in desalination once more.

The challenge with thermal plants lies in the seasonality of the power and water demands; in summer both are near 100 per cent, but in winter water demand is around 80-90 per cent while power demand is lower than 50 per cent.

If the power demand is low while water demand is high, auxiliary boilers need to be operated to supply the steam to the thermal desalination which is inefficient.

Until the beginning of the 21st century, RO was considered an unreliable technology, where thermal desalination was the technology of choice due to its proven reliability in harsh and challenging seawater conditions.

Following improvement in the pre-treatment technologies and the membrane performances, the first successful utility scale RO desalination plant was built in Fujairah, UAE, in the early 2000s.

When the size of the power and water system in a country is relatively small, the cogeneration can provide the power and water economically.

However, as the size of the power and water system becomes bigger, the mismatch in demands widened and resulting inefficiencies require ‘decoupling’ between power and water.

RO desalination gained attention as it can run by electricity only as a stand-alone plant.

Moreover, the advent of low energy RO membranes and isobaric work exchangers halved the energy consumption of RO desalination.

Also in recent years, as countries in the region have been working on reducing their carbon footprint, RO desalination has gradually become the technology of choice in almost all new capacity additions.

The carbon emissions for RO desalination plants depend on the energy mix of the power grid, but it is generally much lower than with thermal desalination.

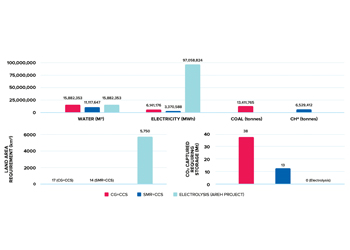

Many of ENGIE’s RO plants are equipped with a solar PV plant within the asset that provides the electricity needed to run the plant.

Examples include two assets in Saudi Arabia currently under construction: the Jubail 3B IWP (570,000 cu m/day of seawater desalination plant) that has a 61-MWp capacity solar facility to help optimise electricity consumption and reduce grid reliance; and the Yanbu-4 IWP (450,000 cu m/day seawater desalination plant) that includes around 10 MWp of solar energy units to reduce grid electricity consumption throughout the desalination process.

Thanks to improvements, the cost of water produced with RO was significantly reduced. The recent IWPs were awarded at sub 0.5 dollars for each 1,000 litres of fresh water out of seawater.

Moreover, if a RO plant is run on renewable power only, it will be producing carbon neutral water.

By operating 15 desalination plants in the GCC serving 10.6 million people daily with potable water, ENGIE demonstrates its commitment to ensuring that communities and businesses have continuous access to high-quality water using the most advanced and efficient solution adapted to the market.

-...jpg)