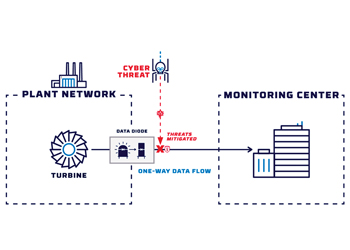

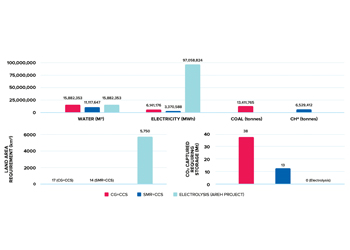

Fig 1 ... Resources required for the production of 1.76 Mt OF H2 from coal or gas with CCS

Fig 1 ... Resources required for the production of 1.76 Mt OF H2 from coal or gas with CCS

Both blue and green hydrogen are essential in the future net-zero emissions economy. Therefore, faster growth is needed over the next three decades to support achievement of net zero emissions targets, says a report by Global CCS Institute

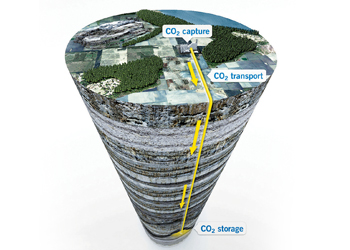

Fossil fuels, such as natural gas and coal, can be converted to produce hydrogen, and the use of carbon capture, utilisation, and storage (CCUS) can reduce the carbon footprint of these processes.

Clean hydrogen can be produced in three ways: from fossil fuels with CCS (blue hydrogen); from biomass; and from electrolysers powered by renewable electricity (green hydrogen) or nuclear power.

This diversity of potential supply sources is an important reason why hydrogen is such a promising energy carrier.

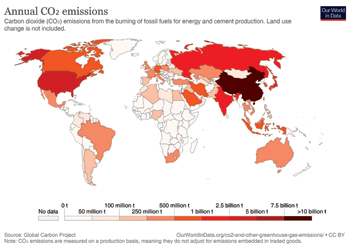

According to the 'The Global Status of CCS: 2021' report by Global CCS Institute, hydrogen could deliver multi gigatonnes (Gt) of abatement annually, when used in various industries, transport and stationary energy.

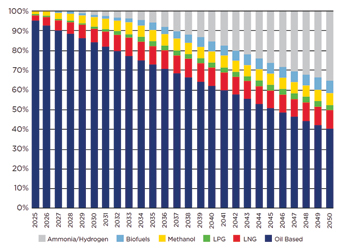

The global Hydrogen Council estimates that hydrogen demand could exceed 500 Mt by 2050, delivering up to 6 Gt a year of abatement.

Achieving 6 Gtpa of abatement, requires that demand for, and supply of, clean hydrogen increase. Two factors critical to realising this opportunity, are scale and cost:

• Production scale must rise from approximately 1 Mtpa in 2020 to over 500 Mtpa by 2050.

• Production costs must be low enough to compete with fossil fuels – taking into account the current policy environment – to stimulate demand.

SCALING UP PRODUCTION OF CLEAN HYDROGEN

|

|

Fig 2 ... Capital cost of essential infrastructure to support production of 530 Mt of |

Blue hydrogen is very well positioned for rapid scale-up, having been produced in commercial quantities (hundreds to over 1,000 tonnes every day in each facility) since 1982.

In comparison, the world’s largest electrolysis hydrogen production facility, powered by wind or solar energy at Fukushima, Japan, can produce around 2.4 tonnes a day of green hydrogen.

There are currently seven commercial facilities producing blue hydrogen. Their total combined production capacity is 1.3 to 1.5 Mtpa, depending on assumed availability.

To rapidly scale up clean hydrogen production, certain resources are essential. The best clean hydrogen production method in a specific location is determined by available land, water, electricity, coal, gas and pore space for CO2 storage:

• Clean hydrogen using electrolysers, or coal or gas with CCS, requires similar amounts of water – around 6 kg/kgH2 for gas plus CCS and 9 kg/kgH2 for coal plus CCS or electrolysis.

• Electrolysis has extremely high electricity demands of 55 kWh/kgH2 compared to 1.91 kWh/kgH2 for gas plus CCS and 3.48 kWh/kgH2 for coal plus CCS, including electricity to produce the gas or coal.

• Renewable hydrogen requires sufficient land to host the wind and/or solar photovoltaic (PV) generation capacity.

• Fossil hydrogen with CCS requires land for CO2 pipelines and injection infrastructure. It also needs coal or gas, and pore space for the geological storage of CO2.

|

|

Blue hydrogen production facilities in development as of June 2021 |

The Asian Renewable Energy Hub (AREH) project in Australia’s remote north-west which, if constructed, will be the world’s largest green hydrogen project, plans to produce 10 Mtpa of ammonia.

This requires approximately 1.76 Mtpa of hydrogen, produced by the electrolysis of water and powered by a combined 23 GW of solar PV and wind capacity located on 5,750 sq km of land

Figure 1 compares resource requirements for renewable hydrogen based on the AREH project, to the same quantity of hydrogen produced from gas or coal with CCS.

Compared to renewable hydrogen, blue hydrogen production requires modest amounts of land and electricity. For example, producing 1.76 Mt of hydrogen (equivalent to one AREH project) via steam methane reformation (SMR) with CCS would require around 14 sq km of land, assuming a 500 km CO2 pipeline in a 20 m wide corridor, 2 sq km for the plant, and four CO2 injection wells situated over a 2 sq km area.

Production of blue hydrogen also requires access to coal or gas and pore space for the geological storage of CO2. Both the coal and gas industries are mature with well-established supply chains, so accessing coal or gas to support blue hydrogen production in any location would be routine.

Global resources for geological storage of CO2 are also more than sufficient for CCS to play its full role in hydrogen production; storage for CCS is ample under any climate mitigation scenario for all applications in all industries.

To illustrate, in an extreme hypothetical case where all 530 Mt of clean hydrogen produced in 2050 is blue hydrogen, annual CO2 storage requirements would be just 7.6 billion tonnes. This compares to a global storage capacity measured in thousands of billions of tonnes.

COST OF PRODUCTION OF CLEAN HYDROGEN

Production costs for clean hydrogen are not just affected by capital requirements. The price of natural gas affects blue hydrogen costs and the quality of the renewable energy resource (which impacts electricity price and capacity of electrolysers) affects green.

Overall, hydrogen produced from coal or gas with CCS is the lowest cost clean hydrogen. It is expected to remain so, except in regions with access to the best renewable resources and lowest-priced renewable electricity.

In addition to the direct capital and operational costs associated with hydrogen production shown in Figure 2, capital is required for essential off-site infrastructure that supports production:

• For green hydrogen, supporting infrastructure includes constructing renewable electricity generation capacity and where necessary, associated transmission lines.

• For blue hydrogen, supporting infrastructure includes CO2 pipelines and the development of geological storage resources.

The capital cost of essential supporting infrastructure is estimated in Figure 2 for two extreme scenarios – producing 530 Mt of blue or green hydrogen (the potential 2050 demand estimated by the Hydrogen Council).

Supporting 530 Mt of green hydrogen would cost over $8,000 billion, compared to approximately $300 billion for blue hydrogen. This covers pipelines, electricity generation and distribution.

There are many assumptions built into these cost estimates. While not definitive, they illustrate that the essential infrastructure required to support production of climate-relevant quantities of green hydrogen could cost 20 or 30 times more than the infrastructure required to support production of the same quantity of clean hydrogen using fossil fuels with CCS.

NEW INVESTMENT

The opportunity for clean hydrogen to offer a decarbonised alternative in industry, stationary energy and transport has supported a wave of new project announcements.

As of September 30, 2021, the Global CCS Institute’s CO2RE Database included 18, either producing blue hydrogen for sale to third parties or for use in production of ammonia, fertiliser and electricity.

The total capacity is uncertain, but considering information in the public domain, it is likely to exceed two million tonnes of hydrogen each year.

There are certainly more blue hydrogen facilities in development than those listed. They will be added as they become sufficiently advanced and defined.

However, even with this recent increase in project activity, clean hydrogen production capacity must speed up.

Faster growth is needed over the next three decades to support achievement of net zero emissions targets. Both blue and green hydrogen are essential in the net zero emissions economy of the future.

-...jpg)