The Ventil test and repair container

The Ventil test and repair container

PreVenTest is an ingeniously designed system for testing all types of spring operated relief valves in-situ, without disturbing the process conditions. This means that there is no dismantling of the valve, so there will be no plant shut-down

A great number of valves in process plants are safety-relevant or at least, have a great impact on the plant’s reliability and availability.

However, quality and safety can be ensured only when valves are given the right treatment. At a time when market conditions and worldwide competition are putting today’s plants under intense financial pressure, maintenance budgets are among the first to be cut. It’s a trend that shows no sign of changing says Arthur Baars, director, Ventil Test Equipment in Netherlands.

'At Ventil we have followed this trend over the past years and responded by developing a variety of products and solutions to reduce or even postpone plant shut-downs related to valve maintenance and repair. We have developed smart tools and equipment which enable valve engineers to trim operational and maintenance costs,' says Baars.

PREVENTEST

One of the most important and cost saving products is the Ventil PreVenTest, the in-situ test system for pressure relief valves. Failure of pressure relief valves to function properly can result in catastrophic damage and life threatening situations. Therefore periodical testing is needed to ensure that they will provide the so important protection, says M S Bala Chandar, director of Ventil’s Middle East operations.

The Ventil PreVenTest is an ingeniously designed system for testing all types of spring operated relief valves in-situ, without disturbing the process conditions. This means there is no dismantling of the valve, so no plant shut-down. There will also be no loss of productivity.

The lightweight and portable PreVenTest system enables the user to prove the correct performance of the valve or identify pressure relief valves in need of repair.

|

|

PreVenTest … online safety valve testing in action |

Welded valves can be accurately tested without costly removal from the plant, and there is no need for uncertain temperature corrections because high temperature (steam) valves can be tested on-site in ‘real’ process conditions, he says.

Here is how it works. A lightweight and fully adjustable test bracket with double acting hydraulic cylinder, a force transducer, a displacement sensor and an acoustic sensor are placed on the valve. To enable the user to execute and monitor the test from a safe distance, the test bracket is connected to the control box by a wear and temperature resistant cable, he explains.

The system automatically applies a proportional force to the valve spindle to overcome the spring tension and bring the valve in a controlled manner to the point where the disc commences to lift (set pressure). The rugged designed PreVenTest computer combines the found test results with the valve data and line pressure. The system then automatically concludes and prompts the set pressure of the valve. The test results and valve data are automatically stored and a detailed test certificate is made available.

The Ventil PreVenTest bracket and intelligent registration software is prepared for testing all spring operated pressure relief valve brands, types and sizes, used in the process and power industries. An ATEX version enables its use in explosive atmospheres and a variety of options is available for testing the most extreme and exotic valve types. The Ventil PreVenTest system is used in 56 countries, approved by a numerous test authorities and recognised by all major pressure relief valve manufacturers, he says.

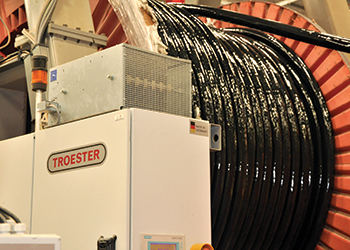

TRANSPORTABLE CONTAINERS

When valves fail to perform and are in need of repair, time is of the essence. To reduce expensive plant down time, full service can be given on-site through Ventil transportable valve repair and test containers. Ventil supplies 10’, 20’ and even 40’ containers, fully equipped and prepared for ‘fast track’ overhaul, repair and testing of valves.

The scope of the transportable valve repair facilities can be fully prepared for pressure relief valves, or have a more universal character for also reconditioning and testing more common shut-off valves and even process control valves. This is based on many years of experience and customer feed-back.

The containers feature all required tools and equipment needed for safe operations and have a high level of quality and finishing. The containers can also be equipped with portable grinding and lapping which enable the service crew to even repair valve in-situ, without dismantling the valve from the plant.

In case a larger amount or variety of valves needs to repaired, a set of special, modular containers can be combined to create an efficient, large scale, on-site overhaul facility. This includes blasting, painting, testing and storage of repaired valves. For offshore applications, the new 10’ or 20’ containers are fully fabricated and certified according to DNV 2.7 / EN 12079. This also includes preparations for the use in potentially explosive atmospheres (ATEX).

The Ventil test and repair containers are delivered as full service and turn-key products, prepared for specific climate conditions and based on many years of experience.

VENTIL VALVE ACADEMY

As the industry evolves and the big crew change marches on, knowledge and hands-on experience become crucial. Well trained personnel is the key to quick turn around and assets optimisation, says Bala Chandar.

Ventil has addressed the growing need for valve technicians by launching the Ventil Valve Academy, a training school for valve experts. The programme starts with the basics and fundamentals about the common valve types and continues with a variety of courses on specific subjects including valve automation, engineering and selection, valve repair and fugitive emission testing. The strength of the ‘VVA’ training courses lays in the great practical character and independent perspective to any valve manufacturer or brand.

The latest is the Ventil e-learning platform. 21 training courses are being made available at www.ventil.nl/valve-academy. E-learning enables valve technicians to start their individual learning journey, anytime, anywhere at any location on any device.

The courses are an excellent solution for technicians and engineers involved in selecting or maintaining valves. But operators and supervisory personnel responsible for process installations will benefit from the broader overview they will get, says Bala Chandar.

The objective of the Ventil Valve Academy is to provide the highest quality and brand neutral information, giving the service provider and plant management the assurance that they have the skilled people they need to maximise asset value, he adds.

.jpg)