Matsubayashi ... taking a quantum leap

Matsubayashi ... taking a quantum leap

Yokogawa has put together a five-year In-Kingdom Total Value Add (IKTVA) plan to be completed by 2022. One of the company’s aims is to improve its IKTVA score as a corporate KPI (key performance indicator)

Yokogawa, a leading provider of industrial automation and test and measurement solutions, aspires to at least double the size of its Saudi business with more local content through the business opportunities presented by Saudi Arabia’s Vision 2030.

'We plan to train and develop 2,000 more Saudis males and female technical resources in addition to the current 550 we already have,' Hideki Matsubayashi, vice president, chief executive for Middle East, Africa & India, Yokogawa Electric Corporation and Ahmad Al-Abdrabbuh, senior executive vice president and board director, Yokogawa tell OGN in an exclusive interview.

Yokogawa has put together a five-year In-Kingdom Total Value Add (IKTVA) plan to be completed by 2022. One of the company’s aims is to improve its IKTVA score as a corporate KPI (key performance indicator).

'We plan to increase the current localisation percentage of 42 per cent to 60 per cent by recruiting, training and developing more Saudis at various levels in the company. Our actions and strategies are aligned with IKTVA as guided by Saudi Aramco and Vision 2030,' they say.

Local procurement, more domestic manufacturing, local supply chain and supplier development are some such dimensions. Yokogawa also wants to increase revenue generated by the export of goods from Saudi Arabia from 3 to 10 per cent.

The technology major will continue working with elite Saudi academic institutions such as the King Fahd University of Petroleum and Minerals (KFUPM) and Jubail Technical College, Jubail Industrial College, Prince Mohammed University, Yanbu Technical College, Yanbu Industrial College and others collaborating in education, research and training for Saudi nationals.

This will provide a constant input stream for local resources that will contribute to a localised knowledge economy. Yokogawa is fully aligned with Vision 2030 contributing to the successful future of the kingdom. Through an MoU with Saudi Aramco, Yokogawa will cover collaborative dimensions including manufacturing, research and development as well as the digitalisation of the oil and gas industry, they say.

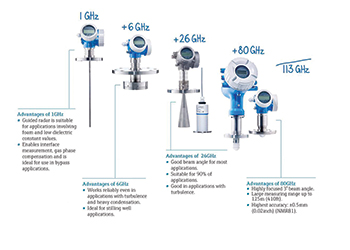

Yokogawa has been improving its line-up of products and expanding their functions for target customers including products that have already been in development. Yokogawa has released more than 20 products since the start of 2015. This includes new versions of CENTUM VP integrated production control systems, Yokogawa’s main product, and the ProSafe-RS safety instrumented system as well as transmitters, Coriolis mass flowmeters and laser gas analysers.

Yokogawa has major ambitions to develop and offer IIoT cloud data services with the best in technology and cybersecurity all with a reduced customer detailed input. Yokogawa is transforming in order to drive incremental business value to its global customer base.

Excerpts from the interview:

What have been the highlights of Yokogawa’s performance in Saudi Arabia and the wider Middle East during the first half of 2017 and how is the trend comparing to 2016?

It has been both challenging and exciting. Continuing effect of low oil prices and consequential dynamics offered significant market challenges.

Stakeholders at all levels revisited plans and even strategies to cope, adapt and thrive. Some investments and projects were postponed or cancelled. Organisations and customers were focused on cost cutting and optimisation.

SAUDI-JAPAN VISION 2030

At the same time, there have been many activities and opportunities including high-profile engagements. The president and CEO of Yokogawa Electric Corporation, Takashi Nishijima, visited Amin H Nasser, President and CEO of Saudi Aramco in October 2016. Yokogawa also participated in the Saudi-Japan business forum meetings for Saudi Vision 2030 in September and October 2016.

|

|

Saudi Arabia’s King Salman with Yokogawa President and CEO Takashi |

The Saudi delegation to Japan was led by the Custodian of the Two Holy Mosques, King Salman. HM King Salman met Nishijima on March 14, 2017 in Tokyo. At the time, a landmark memorandum of understanding (MoU) was signed with Saudi Aramco to cover a number of collaborative dimensions including local manufacturing, research and development as well as digitalisation in the oil and gas industry.

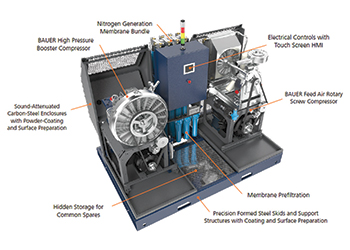

We are looking at co-innovating the future with our key stakeholders in the region to create maximum value for our customers. In November 2016, Yokogawa inaugurated its first local transmitter line in Saudi Arabia. Now that the transmitters have been approved by relevant bodies and customers, Yokogawa is producing and delivering transmitters from its facility in Saudi Arabia in record time.

Despite the downturn, Saudi Arabia has been active with some new awards and a healthy preparation for the future.

In the wider Middle East, we have been successful in adding new customers in the water and power segments reflecting customer confidence in our ability to serve and support.

Can we look at some of the achievements and new contracts during 2016-17?

Yokogawa was successful in adding new customers in sectors other than we traditionally operate in, such as the water and power segment.

Our level of collaboration with key stakeholders in Saudi Arabia and the region has taken a new level. This is exemplified by the MoU signed with Saudi Aramco in March 2017 and the high-level event in Tokyo.

Localisation plans and actions are forging ahead from research and development at our global R&D centre in the Dhahran Techno Valley Dhahran as well as steps towards more local manufacturing and increasing numbers of Saudi nationals providing technical resources.

New projects include Saudi Aramco’s Fadhili phase one and phase two of the Master Gas System (MGS) expansion project. Yokogawa was also awarded a maintenance programme supporting Saudi Aramco’s uninterrupted oil production. PetroRabigh has also awarded a number of upgrades and expansions.

As industry takes advantage of Internet of Things capabilities to improve manufacturing operations, how much has Yokogawa progressed in developing a dedicated IIoT architecture?

In February 2017, Yokogawa announced that it is working with Microsoft Corporation, FogHorn Systems, Bayshore Networks and Telit IoT Platforms to integrate their technologies into an industrial IoT architecture for the delivery of new services. With this architecture, Yokogawa aims to transform its business model, expand its business scope, and help its customers run their businesses more efficiently.

Furthermore, Yokogawa’s wide scope of products, services and development initiatives support its customer’s digital transformation efforts in many ways. KBC Advanced Technologies, a Yokogawa company offers cloud-based services including Data-as-a-Service (DaaS) and a new simulation-based service called KBC Co-Pilot programme. Yokogawa recently released its Process Data Analytics that can detect a decline in quality or productivity at an early stage of the manufacturing process by analysing process data, facility status information, operational history, and other data.

|

|

Al-Abdrabbuh ... co-innovating the future |

Through co-innovation, Yokogawa’s augmented reality programme is designed to provide field workers with maintenance procedures and real-time data via an augmented reality display. Yokogawa is working with customers to develop unique cybersecurity solutions. This is underpinned by Yokogawa’s leadership in measurement and sensing technologies, which are critical for the pervasive use of digital technology.

Do you plan to expand and invest further in the region? If so, kindly elaborate?

The region at large is still one of the most promising globally. As we grow, we undoubtedly would invest in expansions and reinforcing our presence in countries realising most value for our customers and our business alike. For example, an alignment with Saudi Arabia’s Vision 2030 and the signed MoU with Saudi Aramco as well as our IKTVA plan, we are eyeing opportunities presented by the country’s progressive ambition and set plans for growing our business. Our investment in Saudi Arabia will be in line with the vision through exploring opportunities in manufacturing, engineering, R&D, and local resources, training and development.

What are your new value offerings, which would help Yokogawa enhance its customer base and presence in the market?

Since its founding in 1915, Yokogawa has been engaged in cutting-edge research and innovation. Our company’s philosophy is 'As a company, our goal is to contribute to society through broad-ranging activities in the areas of measurement, control, and information. Individually, we aim to combine good citizenship with the courage to innovate.' In the process control domain, Yokogawa introduced the world’s first Distributed Control System (DCS) CENTUM in 1975 which developed into our flagship platform. With the technological evolution of the CENTUM VP R6 DCS system Yokogawa has expanded its range of offerings through pioneering initiatives in the sophisticated fields of Coriolis flow metering, wireless transmission and advanced solutions.

TF2017

These initiatives are a strategic part of an organic expansion towards Yokogawa’s revolutionary ‘Transformation 2017’mid-term business plan intended to take the quantum leap from being a supplier of high-technology products into an advanced solutions provider increasing the value addition to the end-users.

Industrial automation and control, test and measurement, information systems and industry support are the core business of Yokogawa. The objective is to continuously develop and supply solutions and services with optimum quality and reliability thereby contributing to industrial growth. For that purpose, the company has continuously invested in research and development for new technologies.

Yokogawa has been improving its line-up of products and expanding their functions for target customers including products that have already been in development. Yokogawa has released more than 20 products since the start of 2015. This includes new versions of CENTUM VP integrated production control systems, Yokogawa’s main product, and the ProSafe-RS safety instrumented system as well as transmitters, Coriolis mass flowmeters and laser gas analysers.

Yokogawa has major ambitions to develop and offer IIoT cloud data services with the best in technology and cybersecurity all with a reduced customer detailed input. Yokogawa is transforming in order to drive incremental business value to its global customer base. One of the ways the company has transformed itself is through a series of strategic acquisitions including KBC Advanced Technologies and Soteica Visual Mesa. These strategic acquisitions help Yokogawa drive differentiated customer value by discovering areas for improvement, automating the manufacturing processes and sustaining these benefits whilst continuously making improvements.

Yokogawa will continue striving to provide customers highly reliable products and solutions that make comprehensive use of company expertise. It is part of ‘Co-innovating tomorrow’, our corporate brand slogan to continually create value for our customers.

What effect did the entry of new players in the control and information equipment industries have on Yokogawa’s business?

We view the entry of new players as opportunities. Yokogawa continues to broaden its business and value solutions range through ICT, IIoT, and smart digital technologies and services. Yokogawa creates new value with our customers by providing solutions and services for optimisation, sustainability and operational excellence.

How has your strong R&D base given the company an advantage over your competitors?

In line with Japanese culture and Yokogawa’s corporate values since its inception, the company has promoted manufacturing excellence by supplying devices and system with long-term stability. Our R&D base with a healthy expenditure helps Yokogawa be at the forefront of new and reliability-enhancing technologies and inter-operability through global standardisation activities.

What effect did the falling oil price have on business In Saudi Arabia and how are you countering it?

The overall project activity has slowed down due to the relatively low prices of crude oil. In order to thrive under the current challenging conditions, Yokogawa needs to keep reinventing itself. We need to create new value along with our customers to provide comprehensive solutions that are a win for all parties. We have been doing that for many years already, but we want to bring this to a new level. To communicate this Yokogawa Electric Corporation introduced a new corporate brand slogan, ‘Co-innovating tomorrow’, at the time of our centenary in 2015.

This brand represents our determination to create new value by developing solutions in long-term partnerships with our clients. Our traditional customers are oil and gas, chemical and petrochemical producers in the Middle East and Africa where we hold a reasonable market share in these segments.

Aligned with our long-term business plan, we are placing great efforts in developing water and power, renewable energy, mining and extraction industries and the sugar plant market.

Creating new value involves expanding our breadth and depth to maximise our high value-added solutions and services by acquisition and co-innovation. We acquired KBC, Soteica and Industrial Knowledge allowing us to provide a portfolio of comprehensive solutions. The acquisition of KBC means the combined entity has the KBC industry knowledge to identify the value, need, specification and deployment of digital technologies for high value realisation in customer operating assets.

Similarly, what effect does Yokogawa see in its business as result of GCC governments gradually withdrawing energy subsidies and introducing new taxes?

Change is part and parcel of the challenges in today’s market. As Heraclitus said, ‘the only thing that is constant is change’.

Operating plants will be more aggressive in the areas of energy management and optimisation, operational efficiency and market agility. New investments and old operating facilities alike will seek higher returns on investment, sweating the assets and optimising the operation from design to sustained operational aspects.

Realising this Yokogawa must create value for the customer by targeting solutions and services that address the operational cost, energy supply, and demand optimisation. With our recent acquisitions, current and under development technologies as well as accumulated expertise in various industries, Yokogawa is equipped more than ever to support its customers with the needs not only to survive but also thrive and grow with these challenges and changes.

.jpg)