R&D ... research matters for Aramco

R&D ... research matters for Aramco

In 2016, Aramco achieved the industry’s first trillion-cell simulation and hydrocarbon migration algorithm, run on the latest evolution of its POWERS (parallel oil and water enhanced reservoir simulator) technology

Saudi Aramco originates impactful, innovative solutions to make its resources more dependable, sustainable, and valuable – for the benefit of its business, Saudi Arabia, and energy consumers around the world.

Technology and innovation are key drivers of its strategy to maximise the inherent value of the resource base, enable a more diversified and globally competitive domestic market for its products, and create a Saudi workforce with a world-class knowledge base. Aramco realises these goals by developing and commercialising new technologies, evolving strategic alliances with industry partners, forging relationships with world leading research and academic institutions, and pursuing strategic acquisitions and investments to generate additional value.

Its research and development (R&D) efforts focus on the upstream, downstream, and sustainability domains – specifically on high-impact technologies that have the potential to create significant competitive advantage for its operations and help grow new businesses. In 2016, Aramco progressed initiatives across the hydrocarbon value chain, from underwater robotic seismic acquisition and faster reservoir modeling to improved refinery yields and new fuel formulations, Aramco says in its Annual Review 2016.

In its more than 80 years of managing the kingdom’s oil and gas resources, continuous technological innovation has been the driving force behind Aramco’s upstream operations and remains fundamental to its future success. Its technological advances have made exploration more effective and economical, opened new sources of supply, and enhanced its ability to recover more oil and gas to secure sustainable growth.

In 2016, Aramco achieved the industry’s first trillion-cell simulation and hydrocarbon migration algorithm, run on the latest evolution of its POWERS (parallel oil and water enhanced reservoir simulator) technology. Aramco developed POWERS in-house, and at the time of its first deployment in 2000, it was capable of million-cell models. In 2010, Aramco unveiled GigaPOWERS, which ran billion-cell models. Now, the development of TeraPOWERS will make it possible to model the physics of hydrocarbon reservoirs from their original generation to their final production, from microscopic rock pore scale all the way to giant field and even basin scale.

The breakthrough model was made possible through collaboration with the King Abdullah University of Science and Technology (Kaust), located north of Jiddah on the Red Sea. TeraPOWERS will help prioritise prospects, reduce exploration risks and costs, and enable us to sustainably manage the kingdom’s oil and gas resources for future generations.

Led by Dr Ali Dogru, Aramco’s TeraPOWERS team ran the industry’s first trillion-cell simulation and hydrocarbon migration algorithm. The insights generated by TeraPOWERS, combined with data gleaned from core samples, allows for more precise drilling – enabling sustainable management of the kingdom’s petroleum resources for future generations.

Aramco continued to explore geochemical techniques developed in-house, including correlating geotracers – natural compounds found in crude oil – to help evaluate the distribution, migration, and accumulation of subsurface fluids. The knowledge gained from the data generated by these techniques lowers the risks associated with new prospects and and test a range of improved and enhanced oil recovery technologies to maintain its capability to help meet growing energy demand.

Aramco also built and tested two autonomous underwater vehicles designed to acquire seismic data in shallow offshore environments. These innovative subsea vehicles could reduce data acquisition costs by 30 per cent and speed up data acquisition by 50 per cent, providing high-quality data more cost effectively. During 2016, Aramco continued to develop and test a range of improved and enhanced oil recovery technologies to maintain its capability to help meet growing energy demand.

|

Ras Tanura ... planning to deploy new hydrocracking catalyst |

Aramco’s SmartWater Flood research programme continued to show potential to improve oil recovery rates from carbonate reservoirs by an additional 4 per cent to 8 per cent. The results of its in-house research programme and single-well field trials have shown that injected seawater, whose ionic composition has been optimised, outperforms traditional seawater injection.

In 2016, Aramco completed detailed engineering design for the main surface facilities for a multi-well demonstration project at ‘Uthmaniyah, and advanced the design of another demonstration project at Khurais. With a goal to reduce CO2 emissions while also efficiently increasing oil recovery, Aramco continued to monitor the performance of its CO2 enhanced oil recovery demonstration project – the largest such project in the Middle East. Since the initial injection of CO2 in north ‘Uthmaniyah in 2015, the response from the test wells has been positive, with oil production rates increasing three to four times.

Aramco maintained progress on several in-house studies of chemical enhanced oil recovery, including better characterisation of the pre-selected chemical formulation in different rock types, and evaluation of potential synergies with its SmartWater Flood technology. Aramco plans to conduct a single-well tracer test in 2017 to demonstrate the effectiveness of the chemical formulations in the field.

Surfactants are chemicals that reduce the surface tension of liquids, and can be used to help loosen oil from rock. Aramco has conceived and developed sustained release surfactant nanoparticles in-house as a potentially efficient means of enhancing oil recovery. In 2016, Aramco completed new formulations and conducted characterisation and stability tests in support of a single-well test planned for 2017.

Aramco completed integrated reservoir studies for 31 fields and reservoirs, incorporating static data (geology and petrophysics), and dynamic data (well testing and production), to create detailed 3-D models. Applying best-in-class reservoir development and depletion strategies, including advanced well architecture and completion technologies, enables Aramco to analyse the oil recovery performance of reservoirs and manage them for the long term.

Underbalanced coiled tubing drilling allows it to optimise drilling performance and maximise recovery rates from gas wells to help meet growing demand. In 2016, this technology helped mitigate formation damage to achieve a production rate of 60 mmscfd from a gas well. Aramco plans on assigning additional wells to the technology project in 2017 to enable the drilling of areas with low reservoir pressure, without damaging the reservoir.

IMPROVING EFFICIENCY

Aramco continued to investigate cable deployed electric submersible pump (ESP) systems that can be deployed and retrieved in one day using the pump’s power cable, thereby eliminating the need to use a workover rig and significantly reducing costs while boosting oil recovery. Major milestones achieved in 2016 included the testing of ESPs in its Khurais and Abu Hadriyah fields.

Other highlights of its research programmes include:

• High-temperature fracturing fluid system using untreated seawater and designed to conserve freshwater and treated seawater;

• Waterless fracturing fluids based on CO2. This technology uses supercritical CO2 (carbon dioxide in a fluid state) to keep hydraulic fractures open. Aramco synthesised nearly 100 polymers and co-polymers and expect to test them under supercritical CO;

|

Expec Arc ... leveraging new technologies |

• Aramco conducted a successful implementation of using resin-enhanced local sand to fracture a gas well in 2016, with further trials to follow in 2017. This initiative offers the potential to lower gas production costs as well as promote economic development using local resources. Aramco is also identifying locally produced drilling and stimulation chemicals to replace imported versions;

• In a novel approach to address the challenge of losing drilling fluids and mud in drilling operations, Aramco is exploring the potential of local date tree seeds and fibres as loss circulation materials. In 2016, Aramco filed patents for three loss circulation materials and conducted field trials of the seed-based solution. The new products, designed to replace expensive imported loss circulation material, could significantly reduce drilling costs while creating jobs in local communities;

More broadly, Aramco also evaluated a slate of local materials and chemicals for their suitability to replace more expensive imported conditions in 2017.

LEVERAGING TECHNOLOGY

Aramco’s research efforts are aligned with its downstream strategy to integrate its refining and chemical facilities – a synergy that generates a powerful value multiplier effect. In 2016, its R&D teams progressed an array of initiatives to capture additional value through new technologies. These included:

• Crude oil to chemicals: Aramco optimised the conditioning step of pyrolytic cracking of crude oil, employing a novel catalyst system. Work is ongoing to confirm the process, with initial results delivering higher chemical yields than originally estimated, suggesting greater potential to capture additional value;

• Transforming lower value streams to higher value chemicals: Aramco investigated and successfully demonstrated four processes and catalyst options to upgrade the quality of the reformate stream (heavy naphtha processed from crude oil) to produce benzene, toluene, and xylene; and

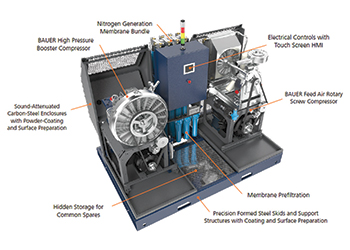

• Developing new catalyst products to increase production of value-added products such as diesel and propylene:

Aramco deployed a new hydrocracking catalyst at its Riyadh Refinery in 2014, increasing mid-distillates by 2 volume per cent. The next step will be to deploy the catalyst in its Ras Tanura Refinery. Aramco also developed a new catalyst for fluid catalytic cracking (FCC). The product, capable of producing an additional 4 per cent to 7 per cent of propylene relative to commercially available catalysts, has cleared the demonstration stage in an integrated FCC pilot plant.

PRESERVING VALUE

Aramco’s ability to reliably and safely deliver its products to customers across the kingdom and to its export terminals depends upon infrastructure maintained to the highest standards – an approach that also improves operational efficiency. In 2016, Aramco continued to enhance its maintenance capabilities with innovative technology:

|

Scientists at work in Aramco |

• Its proprietary Saudi Aramco Inspection Robot (SAIR) is a unique wireless robotic technology capable of conducting visual inspection, ultrasonic thickness gauging, and gas sensing on hard-to-reach steel surfaces. Aramco enabled the creation of a new startup company by licensing SAIR to the Arabian Robotics Company, reflecting its commitment to support new technology-based businesses in the kingdom. Aramco anticipates SAIR will begin inspecting company assets in mid-2017; and

• Its Shallow Water Inspection and Monitoring Robot (SWIM-R) is a remotely operated vehicle designed to perform underwater inspection tasks. In shallow water environments, diving support vessels encounter accessibility and positioning challenges, making the inspection of pipelines in shallow water difficult. In contrast, the SWIM-R vehicle can be deployed from shore or by using a low-cost inflatable vessel, reducing inspection time and costs, and can complete inspection tasks four times faster than divers. Aramco demonstrated the SWIM-R in the Red Sea and the Arabian Gulf, and the technology is protected by seven filed patents.Designed, developed, and tested in less than two years, its Shallow Water Inspection and Monitoring Robot (SWIM-R) enhances pipeline inspection speed, efficiency, and safety. The creation of innovative solutions across its operations underpins its strategy to create greater value.

Its state-of-the-art Detroit Research Centre enables researchers to collaborate with engine designers and major automakers to explore new fuels technology in engines and whole vehicle systems – ideas with the potential to become scalable technologies that can reduce emissions and improve fuel economy.

SECURING ENERGY

Throughout 2016, Aramco continued to explore technologies that will increase the efficiency and environmental performance of fuels derived from oil to ensure future generations can enjoy the economic benefits of accessible, reliable, and sustainable supplies of petroleum while also protecting the natural environment. Aramco is working with auto manufacturers on the advanced integrated engine fuel systems of the future.

Throughout 2016, Aramco continued to advance its efforts to develop new fuel and engine combinations. Aramco plans to create automotive technologies that, in combination with innovative new fuels, can make a substantial impact on reducing emissions and improving efficiency, all while maintaining vehicle performance.

Its technology developments in this area are tested extensively in state-of-the-art research facilities around the world and in the labs of its collaborators – major automakers, engine designers, R&D organisations, and consortiums. At its Detroit Research Centre, five engine test laboratories and its first vehicle chassis dynamometer are now operational. Equipped with this lab, the Detroit team is able to demonstrate new fuels technology in both engines and whole vehicle systems.

Additional highlights from its research into fuel engine systems include:

• Working collaboratively with European and US automakers, Aramco demonstrated significant fuel efficiency and pollutant emissions improvements using Gasoline Compression Ignition (GCI) technology. This was done on several light-duty and heavy-duty platforms using market and blend stock gasoline fuels (like naphtha) instead of diesel;

• In collaboration with IFP Energies nouvelles (IFPEN), Aramco demonstrated the feasibility of octane on demand in a light-duty vehicle. This approach utilises two fuels to supply the necessary anti-knock quality based on engine requirements while improving fuel efficiency; and

• In collaboration with the Kaust Clean Combustion Research Centre, Aramco released two new fuel formulation tools in the public domain. First, AramcoMech 2.0 allows researchers to investigate the combustion behaviour of different fuels under different conditions at a molecular level.

This model has been cited in more than 380 international research institution publications and adopted by leading transportation companies for product development and research. The Fuel Design Tool complements AramcoMech and can be used to develop surrogate fuels that match most of the physical and chemical properties of real fuels.

.jpg)