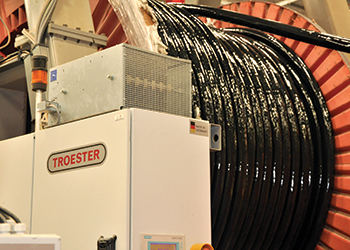

Shawcor ... FlexPipe line pipe being installed next to steel pipe

Shawcor ... FlexPipe line pipe being installed next to steel pipe

Shawcor makes composite line pipe and trains and supports pipe installers for a seamless installation

Corrosion in the oil and gas industry is a common term; something one talks about on a daily basis. Mitigating corrosion is vital to production, associated costs are carefully tracked and analysis is done to determine life cycles. What options do producers have to protect their assets? Most recently the industry has been turning towards composite line pipe over traditional steel to minimise chemical breakdown and extend asset life.

Coming to market almost 20 years ago, spoolable composite line pipe is a relatively new technology. Beyond the main advantages of lower install costs, straightforward installation and the reusable nature of the pipe, it is also corrosion-free. This means significantly reduced corrosion inhibitor programmes and no failures due to rust. Importantly, there is increased safety for installation crews – there are no heavy 12-metre steel pipes to handle.

Composed of several different layers, Reinforced Thermoplastic Pipe (RTP) is a combination of a thermoplastic liner, a reinforcement layer, and a thermoplastic outer jacket. Some offerings are fully non-metallic composite (using glass fibres and tape reinforcement), while others have metallic reinforcement.

Shawcor’s Composite Production Systems group, home to the FlexPipe, FlexCord and FlexFlow product lines, manufactures composite line pipe and trains and supports pipe installers for a seamless installation and full-service offering.

Recently, Petróleos de Venezuela, (PDVSA) selected FlexCord Linepipe Anti-buoyant for gas lift injection lines in Lake Maracaibo, Venezuela, an oil-rich region just larger than 36,500 square kilometres with estimated reserves of 44 billion barrels. Oil production activities started in Lake Maracaibo in 1922, and as a result, there are thousands of kilometres of corroded steel pipe lines in need of replacement. PDVSA decided on FlexCord Linepipe Anti-buoyant for a number of reasons, most importantly its anti-corrosive nature as the environment is susceptible to excessive corrosion thanks to a high salt content and warm temperatures.

In just the first six days of the project, 16 wells were installed with injection lines varying in length from 600 to 4,000 metres. The operating conditions for the project were 1,000 to 1,400 psi and temperatures of 28 deg C to 38 deg C. PDVSA reduced installation time and costs by up to 35 per cent compared to previous installations and repairs using steel pipe.

"The technology has solved a great problem for us," says the PDVSA lake maintenance superintendent. A true testament that composites are the solution to highly corrosive environments.

In another instance, one of Canada’s largest oil and gas exploration, development and production companies, chose to challenge Shawcor’s 3-inch and 4-inch FlexPipe Linepipe product against stick fiberglass to see which product would best meet their needs. They installed both products, in equal lengths (2,030 metres), in Steelman, Saskatchewan, to replace steel lines that had the potential for failure due to corrosion. Not only did FlexPipe Linepipe save the operator 20 per cent on total installed costs, but they were also able to reduce the overall project duration. "Since switching to FlexPipe Linepipe, we’ve increased our installed meterage per day by 50 per cent," confirmed a field consultant for the job.

The operating conditions for the project were 80 to 120 psi and temperatures of 32 deg C to 40 deg C, falling on the low end of the product’s capabilities.

Ultimately, Shawcor’s FlexPipe Linepipe was selected for the job because of its recognised benefits including performance in sour environments, corrosion-resistance, high durability and proven performance globally.

They were pleased with the installation time, reduction in third party costs (eg, casing for road crossings, sand, construction inspection) and smaller right of ways (ROWs) with no requirements to enter the ditch to rake sand. Setup of the ditch did not need to be sloped for better access. These elements resulted in reduced time and trenching costs. Thanks to the success of the project, they would recommend FlexPipe Linepipe to other operators with similar applications.

In the Middle East, the FlexPipe Linepipe product line is very well received, due also to its lack of corrosion. Saudi Aramco has purchased some 400 kilometres of 4-inch FlexPipe Linepipe High Temperature pipe.

.jpg)